| Author | Message | ||

Xl1200r |

I've got a little project going where I need to bend some steel tubing in the 5/8-3/4" range to 90 degrees in a pretty small radius - no larger than an inch or so. I don't have a pipe bender, so I don't know the best way to go about this. I was thinking of filling the pipe with sand or dirt to keep it from kinking and using heat to bend it around something. Better ideas out there? | ||

Ryker77 |

muffler shop and $5.00 bill? Also many dirt track racers, offroad shops, and other race shops have tube benders. Lowes/Homedepot has pipe benders of conduit that might work on heated metal? | ||

Badlionsfan |

yeah, take it to a fab shop that has a mandrel pipe bender and let them bend if for you. | ||

Xl1200r |

I used to work at a garage and we had a mandrel pipe bender, but our dies woudln't be able to accommodate a pipe or a radius this small. I'd really like to be able to do this on my own if at all possible because the angles will likely not be exactly 90 degrees, but I won't know until I need them. | ||

Mikej |

You want to bend a 3/4" pipe around a 1" radius? Is that radius to the centerline of the pipe or to the inside bend of the pipe? Either way it's going to be tight and you might be better off finding a cast fitting to avoid kinking or tearing the pipe. How thick are the pipe walls? Googled up this .pdf for pipes, look at page 7 table 4.2-1. http://engstandards.lanl.gov/stds_dcc/specs/pdf_hi story/15215-R1.pdf | ||

Mikej |

These folks get into some fancy bending work with their projects: http://www.ihpva.org/people/tstrike/building/tubeb end.htm And a link from that discussion on how to build a pipe bender: http://www.lindsaybks.com/dgjp/djgbk/pipe/index.ht ml Fun stuff if you have bandaids and aspirin handy. | ||

Xl1200r |

It doesn't have to be 3/4" tubing, and doesn't have to be as tight as 1 inch... Would I be able to use something like this? http://cgi.ebay.com/imperial-tubing-bender-5-8-o-d -2-1-4-r_W0QQitemZ280223012300QQihZ018QQcategoryZ1 04220QQssPageNameZWDVWQQrdZ1QQcmdZViewItem | ||

Hughlysses |

IIRC, 5X the nominal pipe diameter is the normal minimum recommended bending radius. If you want something tighter, buy a short radius butt-weld elbow and weld it in. | ||

Mikej |

I've used the smaller tubing benders for gas and brake lines, and have used plumbing sized benders for conduit thin walled stuff with variable success. The plumbing pipe benders could work if you get a long enough leverage pipe. If you want to go caveman style you could whittle out a channel in a block of wood about the diameter of the pipe, use a torch to heat the pipe up just short of red, then hammer it around a branch using the carved out block as a forming tool. It works if you have no other way, smoked a bit too.  Having a friend with heavily calloused hands and a high threshold for pain nearby helps as well. Having a friend with heavily calloused hands and a high threshold for pain nearby helps as well.  | ||

Mikej |

Just a thought, but do you have any friends or friends of friends who do commercial electrical work? Some of them have some nice hydraulic heavy duty conduit benders in their trucks. A 6-pack of soda or their favorite beverage should get you a bunch of tubing bent up. Quick and easy and cut to length too. Some of that commercial grade conduit stuff is fairly heavy duty. | ||

Buellinachinashop |

There's no electrical hydraulic or step pipe benders that will do 3/4" conduit in a 1" area. You'd need more like a foot. Its a very gradual 90° made to pass wire through. | ||

Mikej |

You'd be surprised at how creative a thirsty friend will get for a 6-pack. Saw one once rig up a short chunk of drainpipe as an anvil to bend a tight tubing radius around. I stood way back. It worked. The bent piece was then put into service for what it was made for (a short replacement section of framework on an old bike). | ||

Mikej |

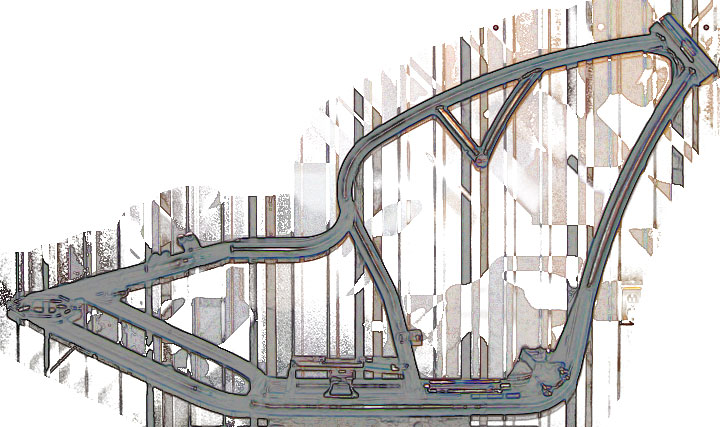

The folks bending up this pipework probably have a pipe bender they don't use much after hours. Shop around your area for a small custom indy bike shop.  http://www.redneckengineering.com/DropSeat-Web-02. jpg | ||

Etennuly |

Depending on a lot of things like how thick the pipe is and how perfect it needs to be, you could weld a 1" dia piece of pipe to a plate and weld a holding pin for the work piece. Heat the work piece and stick it between the two and wrap it around the 1" piece. | ||

Slaughter |

Ok - this is old school but for thin walled tubing in tight radius, we would use glass beads and cap the ends to prevent shifting. The beads would prevent wall collapse. The Brits still use it and our old school Brit machinist had a table of glass bead sizes for use for different wall thicknesses and diameters. Worked like a charm. Remember though, you're really thinning the tension side of the curve with this method. (edit) - you MUST pack the sand in place and really cap the ends... either drive in a tapered plug or actually weld ends shut. San shouldn't be allowed to shift. (Message edited by slaughter on May 06, 2008) | ||

Watrousmark |

Forget the electrical conduit benders, we use a large radius to make it easier to pull the wire. 3/4" ID conduit uses about a 6" radius. If your wall thickness is fairly decent heating and bending a section at a time will work. If you overbend it a bit, let it cool and then straighten it you will get a slightly smaller radii. | ||

Xl1200r |

I'm thinking of just using solid round rod instead - it should still be strong enough and much easier to work with. | ||

Mikej |

Rebar! Easy to find, industrial to look at. Whatcha building????? | ||

Xl1200r |

I'm mounting saddle bags to the bike. Well, actually, I've already done that. I'm remounting them in a much better way. The hoops are going to be mounted to a new pan the clicks into the passanger seat area, so I need to build the supports that will hold the hoops to the seat pan. | ||

Xl1200r |

FYI - project is done... ended up using 5/8" solid rod. Check it out, pretty nice if i say so myself  http://www.badweatherbikers.com/buell/messages/327 77/360741.html?1210707768 | ||

Nillaice |

those should help you with your wheelie issues.  | ||

Xl1200r |

Haha - i think i have some bricks laying around, lol |