| Author | Message | ||

Myclone2 |

2000 Buell cyclone turns over with new battery. No spark seems the stator is bad after testing it with multimeter. The manual says the resistance between the the two stator wires should read .2-.4 ohm. Its jumping around around 1.5 ohm. My question is will this cause a no spark issue or do I most likely have additional issues? It died while I was riding, speedometer started jumping around and ignition started missing and causing muffler explosions. The battery which was 4 months old went bad when this occurred. I replaced the battery and now no spark. Stator test failed. Bike has 20,000 miles on it. Looks like the primary fluid might be leaking near the stator connection beneath and aft of the Voltage regulator. Its obvious I'm going to need a new stator , but would this cause a no spark issue as well. Starter cranks strong and all lights work. + and ground connections look good. Should I plan to replace anything else along with the stator, such as the clutch and clutch basket, shifter paws clips or springs? Thanks. I'm gonna go smell the primary fluid and check the coil wires. | ||

Upthemaiden |

Have you upgraded your primary chain tensioner and replaced the clutch spring plate? I'd at least do those two while you're in there. Shift detent is a plus. Depending on how involved you're looking to get, the starter gasket, crank oil seal, and pulling the stator so you can put some rtv on the wire where it passes through the engine case are all good ideas, but not as important as the first two I mentioned. | ||

Ratbuell |

You could have killed the voltage regulator with the bad stator; that could have caused other (high) voltage issues that could take out other components like the ignition box or the coil or the ignition pickup. | ||

H0gwash |

when my 1988 sportster's cam sensor went out the bike would backfire thru the muffler and freak out and generally be unpredictable. But that bike was much older and had much more miles than your 20,000 mile 2000 bike. I don't think there is a way to test the cam position sensors though other than replacement. | ||

Myclone2 |

Thanks y'all, I have the primary cover off. Now to find these two giant sockets and start making a parts list. Thanks for the suggestions. My shifter is sloppy, only I can find neutral. I can't tell if my tensioner has been upgraded. It was a recall item if I remember correctly. | ||

Upthemaiden |

I just picked up those two sockets at Lowes the other week, they had them on the shelf. Make sure you get the 1-1/8 in a deep socket. The clutch can use a regular socket. | ||

Myclone2 |

What parts will I need for tightening up my shifter? Detent plate, clutch spring plate, are these aftermarket parts. EBay a good spot to look? | ||

Jim2 |

For your shifter make sure that the pins behind the detent plate have not worked their way out. They can be tapped back into place but if they work their way out once they will do it again. This causes the detent plate to sit at a angle and will affect shifting. Some people use red loctite on the pins before tapping them back into place. Also the shift drum channels have a spot that tends to deform and a burr developes making shifting difficult. This burr can be smoothed out with emery cloth and some elbow grease. When you take off the detent plate you will need a new spring clip to put it back together. If you re-use the old one you will chance it breaking in two. Some people do a modification to eliminate the spring clip. It involves bolting the detent plate into place instead of clipping it. Search Badweb and I'm sure you will find the details. The drum is hardened so it requires machine shop skills to drill and tap for the new bolt. | ||

Myclone2 |

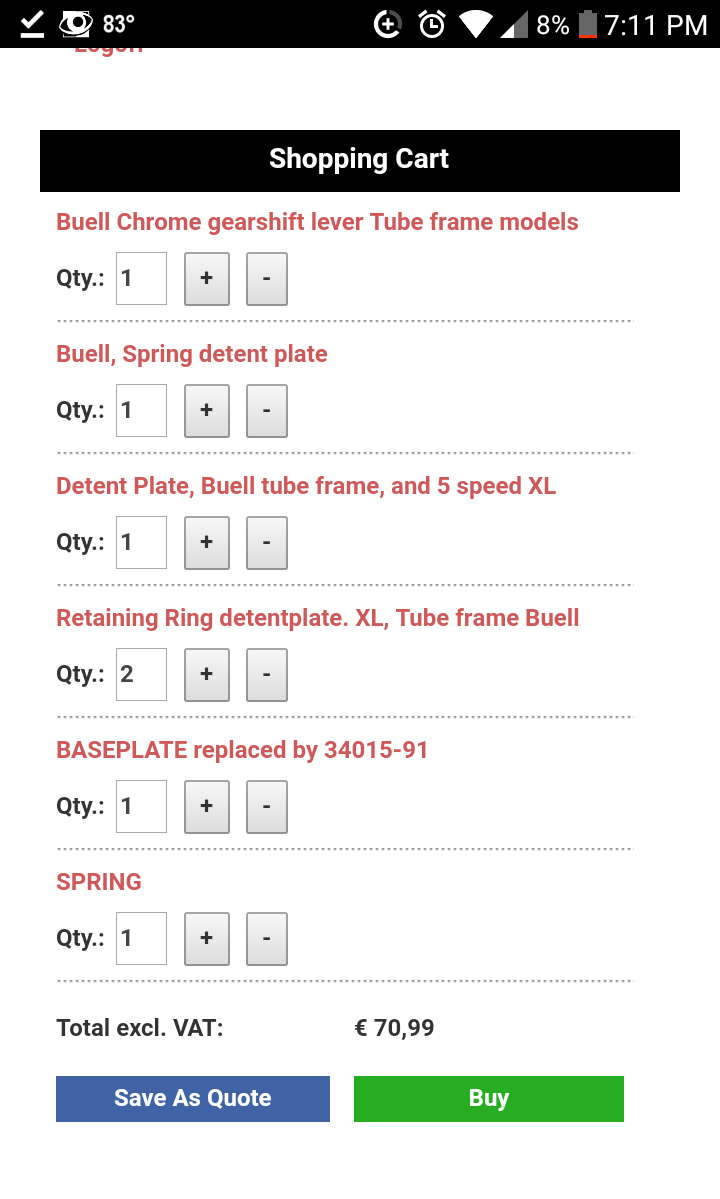

Here's what I have so far. Look good? Missing anything? Twin Motorcycles. | ||

Jim2 |

Not sure what the retaining ring is? You are going to want a new shift shaft seal for putting it all back together. I normally reuse the primary cover gasket but it would depend on the condition of the one you have as to if you can reuse it or not. You asked about how to determine if the primary chain tensioner is old style or new. The primary chain tensioner is a metal back plate that has a nylon sort of material that slide onto the back plate. The old style has a very thin back plate. It's like 1/16" or 3/32" thick. The new style plate is 1/8" or 3/16" thick. That's how you will know. | ||

Jim2 |

If you do take your shift drum out to de-burr the shift channels you will need new stainless steel cotter pins of the right size to re-install the shift channel dowels. | ||

Jim2 |

What is baseplate? If it is the plate behind the trap-door, I don't know why you would need to replace that. | ||

Upthemaiden |

Googling that Baseplate part number just seems to pull up the whole shift shaft assembly. You're welcome to replace that, but unless yours is damaged I'd save the $35. I agree you'll probably need a new primary gasket. Mine was completely shot when I pulled the primary cover off. It was stuck to the engine case and comes off in 1" pieces. I did see someone mention that they use Dow Corning 111 when they install theirs which helps it come off nice and easy next time they pull their cover off. I have yet to track and down though. When I tried to order just the detent plate, Lance also said I should really replace the springs, he put 3 on my order. One is the spring for that piece that's bolted to the trap door that rests on the concave part of the detent plate, the second was the spring for the shift shaft pawl, and the 3rd was the heavier return spring for the shift shaft itself. I'd love to replace the circlip with a bolt, as they're known to be problematic, but I don't have the time for that at the moment. Also, when I ordered my primary gasket, it came as a gasket kit, which included the gaskets for the derby cover, primary chain inspection cover, and the 2 bolts that hold the inspection cover on. I'd also recommend replacing the oring where the clutch cable screws into the primary cover, unless you just left the cable in when you pulled the cover off. | ||

Myclone2 |

Well I have the new stator installed and still no spark, can I test the voltage regulator with a multimeter? That would be the next place to look right? | ||

Jim2 |

The service manual has a good electrical troubleshooting section. Here is the link to the 96 S1 manual. It will work for you. It is in the tech bullitens section. http://www.badweatherbikers.com/buell/Manuals/S1_1 996-1997_Service/intro.pdf | ||

Myclone2 |

Update, I followed the "No Spark" Troubleshooting section in the S1 1996-1997 Service Manual. The resistance between the secondary coils is non existent. So the coil is bad too. I'm kinda relieved and hopeful waiting on a good coil now. I have the 2002_m2-m2l_manual.pdf The 2002 has a completely different electrical set up from a 2000 M2 Cyclone including a different 2 harness ignition module, and a Bank Angle Sensor. Seems that the 96 S1 Manual or a 1986-2003 H-D Sportster Service Manual is more appropriate for the 2000 Buell M2 Cyclone. Valuable information! I was able to find all three meantioned repair manuals for free online. | ||

Hootowl |

.2 Ohms is very difficult to measure with most meters. The difference between .2 and 1.5 Ohms is likely lost in the leads. Still not sure why you replaced the stator trying to fix a no spark condition. | ||

Myclone2 |

Yeah turns out the coil was ok just dirty. I was able to get a spark using the jumper wire. Now I'm looking at the the voltage regulator. Stator failed the test in the book. Said.2-.4ohm good anything higher replace. It was around 1.5 ohm. Something got fried cause it killed a new battery. | ||

Jim2 |

Make sure your voltage regulator is grounded good. Some of them have a wire for ground and that connection can get very dirty or break. I think some of them just ground by screwing to the clean spot on the chassis. When a new voltage regulator is installed some of the powder coat has to be scraped off so that you can achieve a good ground against the chassis. Sometimes people forget to do that | ||

Hootowl |

If the stator output leads aren't shorted to ground or each other (which is very difficult to test with the average meter), and aren't open (which is easy to test) your stator is likely fine. The best stator test is to measure the AC voltage it puts out. That procedure is also in the manual. | ||

Myclone2 |

How do you do that if if won't even run? | ||

Myclone2 |

It smelled like it was cooked to. | ||

Hootowl |

"How do you do that if if won't even run?" The two problems are not related. When you fix the non-running condition, you can check the stator for proper operation. The stator is/was not the reason you don't/didn't have spark. | ||

Myclone2 |

My research has lead me to believe that the malfunction of the charging system damaged one or more ignition components causing the no spark issue. "Think McFly Think!" | ||

Hootowl |

"Think McFly Think!" Quoting the buffoon Biff doesn't exactly come off as an insult to me.  I think you're on the wrong track with regard to the cause of your no spark condition. No spark either means a bad coil, a bad timing cup, or an issue with the associated wiring. Have you checked the timing cup? It's not unusual for them to fail. I don't see how a non-functioning stator could physically damage the regulator or the ignition coil, or anything else for that matter. Other than your wallet.  | ||

Ratbuell |

Stators can fail either short, or open. Open is no output. Short causes an over-volt condition that can easily fry the VR; once the VR fries, excessive voltage can go throughout the entire electrical system. I agree, the bad stator/rotor couldn't be the direct reason there's no spark, since it doesn't cause the spark to begin with. However - if it did fail shorted, and sent an overvolt into the system, the coil or any of the engine sensors or even the ignition box itself, could easily have been fried. THAT would cause a no-spark. | ||

Hootowl |

A shorted stator will only output higher voltage if the stator windings are shorted to each other, effectively putting a portion of the windings in series. His resistance measurements indicate that this is not the case. Unless I misunderstood his first post. | ||

Myclone2 |

Hey guys, not trying to insult just get a laugh. I appreciate any feedback. I'm going to go through the troubleshooting and report back with detailed notes step by step. I'm really getting frustrated with this thing. Thanks | ||

Myclone2 |

Hey guys, not trying to insult just have a laugh. I appreciate the feed back and I am really kinda puzzled by this whole thing. I've eliminated the coil as the problem. The wiring on the frame seams to test good I've followed the troubleshooting section thus far. My results are in all caps, hope this doesn't offend, just trying to be neat. Check for Ignition Spark 1. Disconnect spark plug cables from spark plugs. Check condition of plugs and cables. Clean or replace as necessary. ALL GOOD 2. Insert a conductive adapter into spark plug cable end and establish a 3/16 in. (4.8 mm) gap between adapter and cylinder head. Turn on ignition and “engine stop” switches. With transmission in neutral, press “engine start” button. Check for a spark across plug electrode gap. If a spark is produced, problem is not in electronic system or coil – check carburetion, enrichener and spark plugs. If no spark is produced, check battery voltage and battery connection condition. Battery voltage must be 11- 13 VDC. Charge battery if voltage is low. BATTERY VOLTAGE GOOD 12.38 DCV 3. Verify that the ground strap from swingarm mount block to below the circuit breakers is in good condition. If there is still no spark, then perform the tests under NO IGNITION SPARK below. GROUND STRAP AND BREAKER GOOD NO SPARK No Ignition Spark See Figure 7-2. To conduct the following tests, it will be necessary to assemble a set of jumper wires. Cut two wires of ample length to reach from a good ground connection to the negative terminal of the coil primary. If a suitable capacitor is not available, use a condenser (such as the type used in earlier breaker point ignition systems). When conducting Steps 3 and 5 of the following spark tests, connect a spare spark plug to one of the plug wires and lay the spark plug on the engine cylinder head. During the testing procedures, check for spark across the spark plug electrodes. 1. Ignition switch on. 2. Multimeter red wire to white wire terminal, black wire to ground. 3. Meter should register 12 VDC ± 1.0 volt. If meter is correct, proceed to STEP 2. YES 11.31 VDC PRESENT AT WHITE WIRE GOOD 1. Remove pink (module) wire from coil terminal. 2. Ignition switch on. 3. Multimeter red wire alternately to white wire terminal and to pink wire terminal. 4. Meter should register 12 VDC at both terminals. If meter is correct, proceed to STEP 3. YES 11.31 VDC PRESENT AT BOTH WHITE WIRE TERMINAL AND PINK TERMINAL GOOD STEP 3 1. Pink (module) wire disconnected. 2. Ignition switch on. 3. Jumper wire – connect capacitor wire to pink wire terminal. 4. Connect both wires to common ground. 5. Momentarily touch ground wire to pink wire terminal. When you remove the wire, there should be a spark at plug. If spark occurs, proceed to STEP 4. YES SPARK IS PRODUCED USING JUMPER WIRE COIL TESTS GOOD ON BENCH AS WELL. STEP 4 1. Reconnect pink wire to coil. 2. Ignition switch on. 3. Disconnect sensor. “3 WIRE TRIGGER HARNESS” 4. Connector from module–multimeter red wire to red wire socket and multimeter black wire to black/white pin. Should register 12 VDC ± 0.5 volts. If meter is correct, proceed to STEP 5. I ASSUME 12 VDC ± 0.5 volts MEANS 12 DCV PLUS OR MINUS .5 VOLTS? I GET A READING OF .33 DCV WITH THE KEY SWITCH ON OR OFF. NOT GOOD BAD IGNITION MODULE? STEP 5 1. Ignition on. 2. Momentarily place screwdriver across black/white and green connector pins. Since the ignition module ignores the first four sensor inputs, repeat this step six to ten times. 3. Strong evidence of spark at spark plug when screwdriver is removed. If there is a spark, sensor is suspect. Install known, good sensor and test again. I GET NO EVIDENCE OF SPARK GOOD LOOKS LIKE THE SENSOR IS GOOD. LOOKS LIKE A BAD MODULE PART # PART NO. N0306.9 BHP4 / 31652-96Y | ||

Jim2 |

Did you ever swap the ignition relay for the starter relay? I did not study this enough to know if your testing bypasses the relay. I would hate to see you buy a new ignition module if it is just a bad relay. |