| Author | Message | ||

Resinears |

I bought some new rubber for the M2 after suffering a couple of flats. Invested in some tire irons, rim protectors, a simple balancer, etc. After doing the front wheel, I tackled the rear which was really stiff. My knees are bruised and sore, and my hands were really stiff, but I got the tire on the rim and had to walk away before putting the wheel back on after loosing my patience. I have a Baker chain conversion, where the rear sprocket is bolted on to the wheel. The bolt heads that hold on the sprocket make sliding the rear spacer in place after the wheel is centered in the swingers impossible: the spacer and wheel have to go into position together. Same difference with the brake caliper on the left side. I assume the skinny washer that fell on the floor when I yanked out the axle goes between the caliper and the outer wheel bearing on the brake rotor side. Because the wheel bearing is slightly recessed on this side, the caliper has to also be in position (with the flat washer as well) to get the whole assembly in place. What's the %^%^#$% trick to getting this mess back on? I'm sure it will be easier next time... | ||

M2x2 |

Take 1 of the sprocket bolts off. Place the wheel with the caliper bracket and slide the axel part way in, slide the right side spacer in place where you removed the sprocket bolt, slide the axel the rest of the way in. Replace the sprocket bolt. Easy peasy. | ||

Resinears |

That will work! Thanks a ton! Sort of how I defeated the front wheel caliber removal (until I found out on reassembly that you don't have to take the front brake rotor off - just have to hold your lip "just so"). I have to say that by the time I had got those tires off and on the rims with levers, I was just too whipped to problem solve effectively. Thanks again!! | ||

Upthemaiden |

Awesome job on changing your own tires. I started changing mine a few years ago. I think the first time I did it I spend pretty much a whole weekend wrestling with those tires, taking a break, and coming back for more. After a handful of tire changes I can get the tire off and on the rim in a couple mines and without any swearing haha. Tools help too. I started working on the floor with 2x4s under the wheel and some shorter tire levers, and slowly get better at it. I eventually grabbed the harbor freight tire changing stand with the motorcycle attachment, and a no-mar bar, and it couldn't really get any easier. Anyway, as far as the back wheel, I just changed mine a couple weeks ago. I remember my method was to slide the axle in just far enough to hold the brake caliper in place(make sure you put the caliper stop in the slot on the swingarm!). I put a 2x4 on the floor under the rear wheel to semi hold it in place, then I held the right spacer against the wheel and slide it into place and sliding the rotor into the caliper at the same time. Scoot the wheel forward enough to get the belt/chain on, then pull the wheel back, get it as lined up as you can and start sliding the axle through. A rubber mallet helps there. At that point it's just a matter of trying to get all the holes lined up enough to get the axle slid all the way through. I'm not sure how different things might be with the chain conversion, but I can't imagine it's much different. It sounded like you also had a spacer on the left side? I don't remember having a spacer there, it was swingarm, brake caliper bracket, wheel, spacer, swingarm. I'm not the original owner, so if there was a spacer, it may have disappeared. | ||

Upthemaiden |

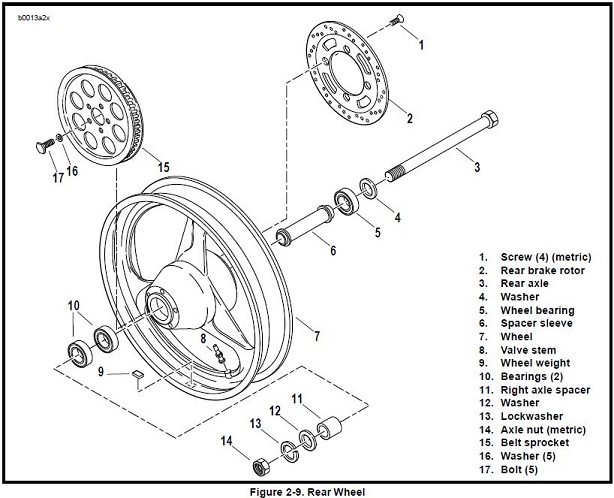

I'm wondering if the left side spacer you're thinking of is #4, which if I remember right, goes on the outside of the swingarm, between the head of the axle and the swingarm. I couldn't find a good picture in the manual of the wheel in the swingarm to show the actual orientation of the wheel/axle/brake mount/swingarm all fitted together.  | ||

Resinears |

Upthemaiden, I ended up doing the same thing with a 2x4 and some other stuff under the wheel to more or less get it lined up. The "spacer" I talked about was a washer that hit the ground when I initially pulled the axle out and tried to drop the wheel (without removing the brake caliper 1st, doh!). I surmised that the spacer came from between the caliper holder and the wheel bearing on the brake rotor side, based on the smudge and wear marks on the wheel bearing, caliper holder, and inside of the swing arms. I too had looked at the diagrams in my manual, but they don't show the relationship at all. To further confound things, my bike has the baker chain conversion, so I thought things might end up being slightly different. FWIW, my spacer (#11) looks like a machined pulley, about 2" in diameter. Maybe the washer I was trying to put in on the brake rotor side should have been on the drive side... As it is, everything rotates smoothly, and the chain looks centered to the sprocket, but now I'm thinking that if all else was stock, it would have been A LOT easier if there were no washer between the caliper carrier and the wheel. I was attempting to do the remount exactly as you described, but you can imagine that that doesn't work when there is an extra washer between the caliper bracket and the wheel. It seems that everything together was the right width for the existing space between the swingarm's sides, but next time I think I'll be trying without the extra washer. Thanks for your observations! | ||

Anonymous |

Lookup Ziptie method for motorcycle tire change video. No levers or spoons are needed. The only trick is breaking the bead. I use HF bead breaker tool for that. I used to use 2X4's and my jeep bumper. -Jim2 (Message edited by jim2 on June 02, 2017) | ||

Upthemaiden |

Did you still have a washer between the head of the axle on the left side, and the swingarm? I just went and double checked. I had a washer on the outside of the swingarm, then nothing but the caliper bracket between the swingarm and the wheel on the left side. On the right side I had that same large washer, looks nothing like the one in the diagram above. Mine has the steel swingarm, I'd assume the aluminum would be the same. Keep in mind, if you're not the original owner, someone before you could've put things together in any order. The chain conversion might've changed things too, although I'm not sure why it would have. | ||

Resinears |

Yes - still had the washer between the head of the axle and the swingarm, with the brake caliper and another thin washer between the swingarm and the wheel. I'm thinking that washer between the caliper and the wheel shouldn't be there the more I ponder it. No matter what kind of modification to the sprocket side got made, there shouldn't be any extra shimming required on the left side of the wheel. Given that whatever poor diagrams I've seen haven't hinted at this extra part, and your comment that there isn't one in your assembly (albeit your swingarm is steel) all provide me with confidence that this part will not end up back on my bike (at least on the left side of the wheel) next time I take the tire off.... (Message edited by Resinears on June 05, 2017) | ||

Tripper |

Any tips for getting the rear axle out? Its been sitting more than 5 years. Used dead mallet to get it flush with right swingarm and am stuck. I can rotate it by hand but cant make any more progress pulling it out. | ||

Resinears |

Swear at it, spray the exposed side with penetrating oil, tap it back into place, spray some more, tap back out, repeat until it frees enough. You could probably use a 3/8 or 1/2" extension as a drift to pound (tap) it through. Sorry if you tried all of this. Did you remove the brake caliper? | ||

Dave |

What Resinears said about working it back in. I presume rotating by hand didn't mean fingers... Use a larger wrench as a fork around the axle and tap out hitting the wrench (I have an adjustable wrench size Big Ass ...SAE) DAve | ||

Tripper |

Its out thanks to a large drift punch into the hollow axle. Very corroded and I fudged the threads up. Looking for a new axle. | ||

Harleyelf |

Brass makes the best drifts, softer than your threads. Closest size possible to the part being removed is best. | ||

Big_jim59 |

I know that this is an older thread but I find myself in the same predicament with my M2 Cyclone. I pulled the rear wheel to install new rubber. It has been a few days and reassembly has been a bear. I didn't think there was a spacer between the caliper holder and the wheel bearing but my caliper rubs the disk when everything is done up. | ||

Ratbuell |

USE ANTI-SEIZE. Coat the axle with that stuff when you reassemble. If you make a sloppy mess...you've just about got enough in there. Seriously. | ||

Big_jim59 |

Well I found the problem. I had my swing arm stand slightly out of adjustment and it was rubbing the real pulley. I moved it over with a big screwdriver and all is good. The wheel is a real bear to get back in. It's heavy, there are a bunch of parts that have to line up and the right side spacer has a mind of its own. I made a prop for under the tire out of some scrap lumber that kept me from having to hold the wheel in the air while I stabbed that axle. | ||

Upthemaiden |

I was gonna say... as I was reading that I was thinking I should get some wood, put the bike on the rear stand and cut the wood so it just fits under the rear tire. That way any time I'm putting the wheel in I've got something that'll hold it to the perfect height for reassembly. It'd be off slightly depending on tire wear, but you take what you can get. | ||

Williamscottrobertson |

I had the exact same issue on my S1W a couple weeks ago. Took me a minute to notice the paddle sticking out toward the inside of the swingarm about half an inch. | ||

Big_jim59 |

In the last week I had to fit a new tire to my 2000 Honda VFR800. I took the wheel to the same shop for the tire install. They tech remembered me and remarked at how light this wheel was compared to the Buell. It really was quite shocking the difference, granted the Buell had the drive pulley fitted. | ||

Upthemaiden |

"... as I was reading that I was thinking I should get some wood, put the bike on the rear stand and cut the wood so it just fits under the rear tire." I had never seen it before, but apparently they make something for this exact thing... https://www.pit-bull.com/motorcycle-stands/dual-sw ingarm-rear-stands/pit-crew-tire-wedge-f0102-000 Probably not worth the money if you're not using it constantly, but still. | ||

Jayvee |

I once made sort of a similar wedge from a piece of 2x4, cost $nothing, pretty helpful. |