| Author |

Message |

Alfau

| | Posted on Wednesday, September 02, 2015 - 06:32 pm: |

|

another innovation by someone |

Tony302

| | Posted on Wednesday, September 02, 2015 - 11:48 pm: |

|

Man the ideas just keep pouring on in |

Harleyelf

| | Posted on Thursday, September 03, 2015 - 05:14 am: |

|

That's my innovation; I was looking for the photo to add to this thread, thanks, Al.

It's a new style shock on an old style front mount. The hat adds just enough length to lower the rear by about an inch.

Anyone got a source for M2L sidestands? I have to be careful where I park. |

Bsanorton

| | Posted on Thursday, September 03, 2015 - 08:48 am: |

|

Harleyelf can your welder make a few up for us? I'd like one myself. Thanks |

Dvc357

| | Posted on Thursday, September 03, 2015 - 09:06 am: |

|

Hey Brothers

Count me in on that! |

Harleyelf

| | Posted on Thursday, September 03, 2015 - 11:23 am: |

|

He's in Florida and I moved to Wisconsin a year ago; I doubt he kept a drawing of it. It's a simple stainless steel box, a tight fit on the shock and the rear bolt pivots at the swing arm. I can take measurements for anyone who PM's me, but you guys all have the newer front mount so that wouldn't work for you unless you kept your old mounts. |

Midknyte

| | Posted on Thursday, September 03, 2015 - 03:17 pm: |

|

>Anyone got a source for M2L sidestands? I have to be careful where I park.

My dealer found one on the parts network / lookup. Y'all shouldn't afraid to go in and ask...

Edit: shouldn't

(Message edited by midknyte on September 03, 2015) |

Midknyte

| | Posted on Thursday, September 03, 2015 - 03:21 pm: |

|

>Harleyelf can your welder make a few up for us?

Do note that he is using an old front mount in combination with that. That hat alone as shown will move it back much more than the 3/8 to 1/2 inch you want.

Whatever is done must also be rigid. You do not want the shock to flop around on compression. (Yes, technically extension internally).

(Message edited by midknyte on September 03, 2015) |

H0gwash

| | Posted on Thursday, September 03, 2015 - 08:37 pm: |

|

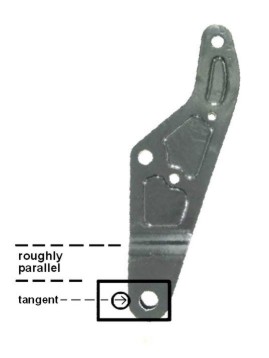

This project evolved a bit, which is why there are extra holes here. The welder, Hansen Machine Works in Sacramento, CA suggested cutting off the holes on the original old style mount and matching up the pieces of steel with holes properly before welding them back together. This is TIG welded, cost something like $40.

Of course, the next problem was the sidestand. I put the bike on the race stand, removed the kickstand and cut out about 1.25 inches with a dremel, cleaned out the inside and stuffed a 1/2 inch dia threaded rod in there gooped with plenty of marine epoxy and I was ready to ride it the next day.

(Message edited by h0gwash on September 04, 2015) |

Midknyte

| | Posted on Thursday, September 03, 2015 - 11:16 pm: |

|

One M2 Low shock, received. I'm choosing this route since it was an oem solution and is reversible if I sell and next owner wants things back to normal. Though, if this works, I don't imagine wanting to give it up anytime soon.  |

Midknyte

| | Posted on Saturday, September 05, 2015 - 03:18 pm: |

|

I won't be getting things put together for a few weeks at least, but I do have information to share. The M2 Low sidestand is the same length. Don't waste time or money fetching one.

|

Harleyelf

| | Posted on Saturday, September 05, 2015 - 03:43 pm: |

|

Thanks. Must go the shortening route. |

Robertl

| | Posted on Saturday, September 05, 2015 - 04:46 pm: |

|

I bought this for my wife's bike when I lowered it but never installed. It didn't seem to need it but I might actually install it over school break since we hope to start riding again now that cooler weather is approaching:

http://www.shop.motowerk.com/Flatfoot-for-Lowering -Kit-KN65ER-FF-LK.htm

If you want to cut down and reweld the original, this guy put all thread inside to strengthen it:

http://www.sportbikes.net/forums/fz6-fz6r/314081-b est-way-shorten-kickstand.html |

S1owner

| | Posted on Saturday, September 05, 2015 - 08:09 pm: |

|

Cut stand in middle bevel the edge put a sleeve in that fits snug keep cutting and trying till you getvthe right hieght bevel edge of bottom make sure the to old edges dont touch leave a hair between weld up you should penetrate all three surfaces.

Grind sand and paint |