| Author | Message | ||

Shupe |

My M2 started blowing oil filter gaskets. Once the first one blew, it blew about 3 more shortly after startup. I tried various degrees of tightness on the filters - didn't matter. Oil pressure is forcing a small section of gasket out and blowing oil out. Return to tank is spotty, just a little oil spitting out. I removed oil pump. It looks fine, nothing clogging the return part. I haven't pulled the cam cover yet. The hole in the gearcase to drain oil to the return section of the pump: does anyone have a pic of an empty gearcase showing the hole from the gearcase side? Sticking a weed wacker string up from the oil pump side - it goes in less than an inch and is obstructed, by what, I don't know. Not sure what's going on here. Shupe | ||

Buellistic |

With the oil filter gasket and gasket surface clean, run the oil filter on finger tight and then tighten 3/4 of a turn ... | ||

Shupe |

Believe me, it is not a filter installation issue. I've exhausted that possibility (and I've installed hundreds of oil filters over the years). It's an oil pump return issue. I've also eliminated a kinked or blocked return line as a possibility. Any theories appreciated. | ||

Buell_bert |

OK this may not be the problem but I have had this happen on cars. The old filter left it's gasket on the mating surface and the new oil filter mated up to it and blew 4+ quarts on my driveway right on startup. There should only be 1 gasket, not 2 piggybacked. Since then I always look under my vehicles after the oil change and right after it is started. Let us all know what you find. | ||

Shupe |

Good idea (that's happened to me working under a car in dim light), but not the case here. | ||

Mighty_mouse |

Do a google image search for "sportster cam install". Looks like a oil galley In the case. Have you tried to use some low psi compressed air to see if its blocked? MM | ||

Odd |

Just throwing it out there but what about the ball and spring behind the oil filter adapter, | ||

Reepicheep |

If the pressure is ***increasing*** on the filter, I guess the only way it could happen is if something on the output side of the pump is blocked. So instead of circulating, it's just ramping up until the weakest link lets go, which makes sense that it would be the oil filter gasket (probably a good thing too, it's a mechanical fuse in the system that is avoiding much worse things). | ||

Shupe |

If the pressure is ***increasing*** on the filter, I guess the only way it could happen is if something on the output side of the pump is blocked. So instead of circulating, it's just ramping up until the weakest link lets go, which makes sense that it would be the oil filter gasket (probably a good thing too, it's a mechanical fuse in the system that is avoiding much worse things). That's the conslusion I reached. I replaced the check ball and I can push it in with my finger easily enough. I'm focusing on the drain from the cam chest to the pump. I'd like to see a pic of the hole in the cam chest floor that drains into the return side of the pump. | ||

Reepicheep |

If you havent done it yet, drop the oil pump and look up into the cam chamber at the pinion gear. You will see the view that is the picture if you click my ID to the left and look at my profile. I don't think that is the problem, but it is a semi-chronic issue on the tubers, so its something you want to check anyway. Check it in a few positions. Or just pull the cam cover and check everything and be done with it. One factory cam in my M2 had crappy hardening from Harley and was grooved. Found it before it did any damage. (Message edited by reepicheep on October 02, 2014) | ||

Buellistic |

Have you done anything with the oil lines ??? | ||

Alfau |

I drilled a hole through the pump end of the oil line, tied rope through the hole and pulled hose through from the oil tank end leaving the rope to reverse procedure for the replacement. as easy as shitting in bed and kicking it out. Make sure you flush the oil tank to remove any gunk. Remove the oil filter and service pressure release valve. OIL PRESSURE See Figure 3-50. The oil pump is nonregulatory and delivers its entire volume of oil under pressure to the oil filter mount. When an engine is cold, the engine oil will be more viscous (i.e., thicker). During start-up of a cold engine, oil pressure will be higher than normal and oil circulation will be somewhat restricted within the oiling system. As the engine warms to normal operating temperature, the engine oil will warm up and become less viscous — oil pressure decreases. When an engine is operated at high speeds, the volume of oil circulated through the oiling system increases, resulting in higher oil pressure. As engine speed is reduced, the volume of oil pumped is also reduced, resulting in lower oil pressure. To check oil pressure, use OIL PRESSURE GAUGE (Part No. HD-96921-52A) and OIL PRESSURE GAUGE ADAPTER (Part No. HD-96940-52A). Remove oil pressure indicator switch and insert pressure gauge fitting. See Figure 3-51. Ride motorcycle at least 20 miles (32 km) at or above 50 MPH (80 KM/H) until engine oil reaches normal operating temperature. At 2500 RPM, oil pressure will vary from 10-17 psi (69-117 kN/m2). At idle speed (950-1050 RPM), oil pressure will vary from 7-12 psi (48-83 kN/m2). GENERAL See Figure 3-58. Oil is pressure-fed from the oil pump to the filter mount (4) via a hose (5). Oil travels through the filter mount into the filter via outer filter holes. Adequate oil pressure activates the oil pressure indicator switch (6) in the filter mount, which turns off the oil pressure indicator lamp. The check ball (2) in the filter adapter (1) “opens” at 4-6 psi (28-41 kN/m2) oil pressure. Filtered oil leaves the filter, flowing past the check ball. | ||

Buellistic |

Alfau: Very good "INFO", you have broaden my mind !!! Guess the mooslambs have not taken over AUSTRALIA yet as you are still on BWBers ??? | ||

Shupe |

thanks for the responses. To respond: - I have the pump out, it looks fine. - I've replaced the oil lines and flushed the tank. I'm sure the return line is clear. Made no difference. I guess I'll have to pull the cam cover. Shupe | ||

Buellistic |

Just a thought, "BUT" no one has asked do you have the right oil filter ??? | ||

Alfau |

Could also be that HD changed the timing cover gaskets in 2000. http://xlforum.net/vbportal/forums/showthread.php? t=858305 Buellistic! There is an invasion throughout the world caused by the clitless fleeing their blissful lifestyle. No sign of it taking over here yet. I'll keep an eye out. Cheers for caring. | ||

Buellistic |

Another thing that has not been asked ??? What changes did you make before you had this problem ??? Alfau: There is not enough of them here yet for them to start pushing their will and pleasure !!! (Message edited by buellistic on October 04, 2014) | ||

Shupe |

Another thing that has not been asked ??? What changes did you make before you had this problem ??? Alfau: I made no changes. It blew a filter gasket out of the blue. Then blew 3 more in quick succession. I changed the lines, blew them out once in place to make sure the return was clear. I also swapped out the check ball and flushed the oil tank with diesel fuel. I put oil in, started it up and within a minute it blew another filter gasket. The filters I tightened normaly just blew to where you could see a small section of gasket sticking out and oil pumped out. For the heck of it, I tried tightening one of them really tight. It blew too, spurting oil out about 12 feet. That was a K&N filter which have a slot in the metal filter housing in which the gasket fits. Shupe | ||

Buellistic |

Try another brand of oil filter !!! | ||

Alfau |

http://www.ertproducts.com/H-D_OIL_PRESSURE_FACTS. html worth a look. | ||

Kalali |

Out of curiosity, did that happen at idle speed? Seems more than only 10psi | ||

Screamer |

In the late 90s, we saw a few circumstances where excess crankcase sealant (factory applied) in the flywheel cavity came loose, migrated and lodged in one of the oil passageways. The symptom was oil leaking (blowing) from every where - it could not return to the tank. This may not be what Shupe is experiencing but it might be something similar. | ||

Oldog |

I am with Lafayette try another filter. then check the filter mount for a flaw ( crack or chip ) perhaps run an oil pressure test at the pump, cold the engines can reach over 30 psi ( i have a gauge on mine ) normal cold idle pressure is about 15 psi for my x1 | ||

Shupe |

If anyone is curious about this old item, here's an update. I removed the cam cover. Using compressed air, I verified that all oil passages were clear: -from filter mount to oil trough in case. -from each oil hole in trough to lifter bore. -Pushrods interior passages -rocker tips to oiling hole near the valve -cam cover hole to pinion bushing in cam cover -checked oil pump for any obstructions/junk - it was clean. Everything seemed to be fine. Then I looked at the end of the pinion shaft. The hole there is small and hard to see, but I pulled a small sliver of aluminum out of there. It appears there is more junk blocking the hole there. Where did this tiny aluminum junk come from and how to get the rest of it out? I think I'm screwed. (Message edited by shupe on November 04, 2014) | ||

Kmbuell |

I took a non-running S2 apart a few years ago that didn't seem to have a good reason for spinning the cam bushings. It had a complete new top end on it. Seemed strange that the cam chest was full of oil. Dropped the oil pump and it was packed with tiny aluminum pellets. Pretty sure it had dropped a valve and somebody threw a top end at it. The crank chopped up the piston parts into small enough parts to get picked up but they just packed all the passages. No oil return, pumped the oil tank dry. What a mess. Then found out there are no oversize cam od cam bushings. Any chance this motor has has a catastrophic failure in its past? Kevin | ||

Shupe |

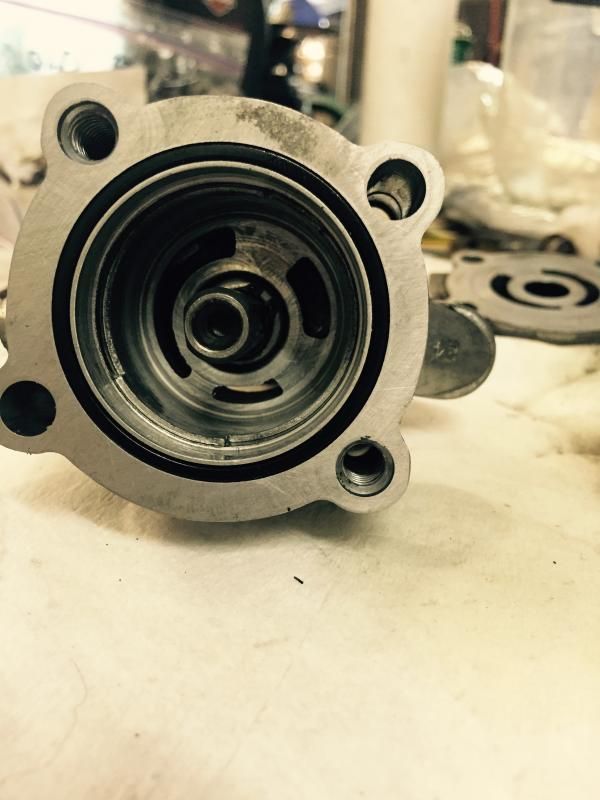

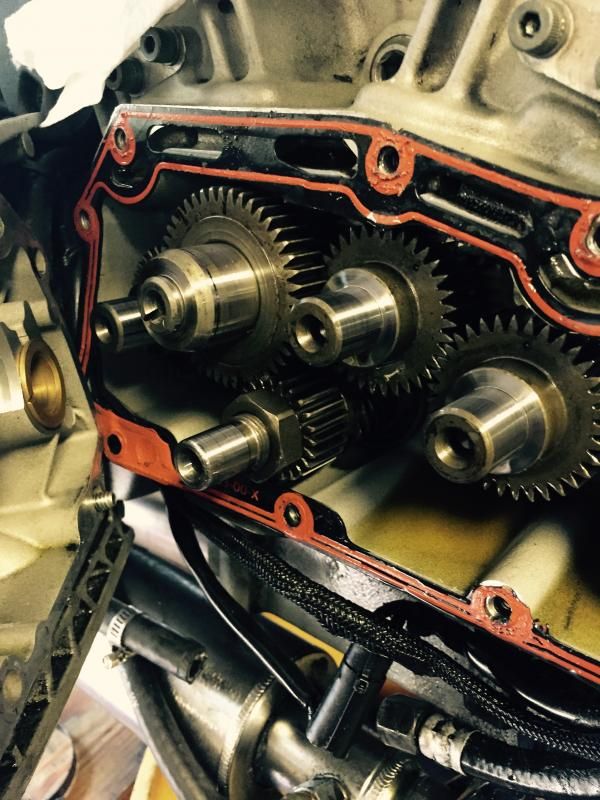

Any chance this motor has has a catastrophic failure in its past? Kevin No, but i'm beginning to think something broke a chunk off and I've got debris in the bottom end. The cam chest and oil pump were very clean, though. Oil pump showing the (clear) drain channel.  Cam Chest  Tiny piece of aluminum in pinion shaft hole. Yes, it's small, but so is the hole. There's more in there still.  | ||

Oldog |

Shupe is your oil pump bottom scored? | ||

Shupe |

<<Shupe is your oil pump bottom scored? No. It looks pristine, really. The filter should have caught that piece I got out, so WTF? | ||

Jolly |

Any chance that's a portion of a thread from the bolt or threaded hole for the timing cup? Have you checked those threads to see if they are damaged? Might help show how much more metal there could be. Or the oil pump drive gear had a tooth sharpened then it chipped off, but it looks more curved like a thread stripped out. Just a thought... | ||

Natexlh1000 |

Oh no. This is starting to sound like the issue I have been trying to figure out with my 1979 ironhead. If the oil pump looks pristine, is it possible that it was replaced? The crime my old iron is guilty of: Two needles from the cam followers fell into the pump and it stopped pumping oil back to the tank. Recently, I finally assembled it with its new cams, oil pump, and cam followers. It ran and pulled fine. Didn't even leak! I changed the oil and rechecked my filter for stuff and no oddities were found. Rode it to work and it puked oil out between the pump and engine case. It's acting like something is blocked up in there. Surfaces are flat and gasket was swapped all without having a good effect. Then I had twins and it's been sitting there in my garage like a disco era monument to AMF quality control ever since. |