| Author | Message | |||

Jim2 |

Only about 75 yards from the turn to my subdivision and I hit a nasty ridge in the crappy road. Snap!, and my bike was buzzing. At least I was close to home.  Gonna have to dig this out  Time to gather a parts list and re-read some old post. | |||

Petethekiller |

I have a spare I'll part with for $25.00 plus shipping. | |||

Buellistic |

Jim2: REVERSE FLUTE DRILL !!! PROPER INSTALLATION !!! Help available when you need it !!! | |||

Jim2 |

@Petethekiller, I may take you up on this so dibs. Does your spare motor mount have the tab to mount the factory OEM airbox to it? I just checked and the billet replacement from American Sport Bike doens't seem to have the tab(American Sport Bike part # 16031 for XL). I still run my OEM airbox and would like to continue to. @Buellistic, Will the bolt extractions kit that Al at American Sport Bike has do the trick(American Sport Bike part # A16323 - 96-02)? Any pros or cons to using it other than I don't know how to use it. | |||

Petethekiller |

sorry for the late response....The tab has been cut off by the previous owner, it also was professionally repaired as it broke just like yours. I ran it as is for about 5 years without any troubles, I just bought a new billet one to replace it. If you still want it let me know. I'd run with it if you dont need the tab. | |||

Jim2 |

Hey Pete, thanks for getting back with me. I'll pass on it because I want to keep the factory airbox. Lafeyette told me that I could have a good welder weld it and it would be good. Your testimony follows that conversation! Around here it's hard to find someone to do a simple job, they don't want to be bothered with it. You have to talk them down more than half what they ask to even make it worth it. I'm also afraid of alignment issues if I can't take the mount and the bike to them and I'm not able to do that. I put an ad in the parts wanted and I hope to hear from someone soon. If not I can still get if from the Buell dealer. | |||

Dannybuell |

I had broken bolts 3 times until I found some better than grade 8 bolts. The mount! wow! Buellistic/LaFayette has it right. they come out real easy with the drill in reverse. All you do is drill a small pilot hole then put the tip of the extractor into the hole. If you can put enough pressure on the broken stud with the bit, you may not even have to drill a pilot hole. | |||

Lakes |

Jim2 do you have pic's of the Billit mount on your bike? sounds good. my M2 2000 came to me from e bay with one broke front engine mount bolt. i replaced both bolts with Allen Head equal to the old Unbrako brand. what are the bolts you use ? thanks i'm in Australia. so want a bullit proof set up for out rough roads. | |||

Jim2 |

Lakes, I never purchased the Billet mount. I want to run the OEM factory airbox and the Billet mount does not have the mounting arm and it costs a lot more. I've just placed an order for a new OEM mount. The original bolts for this are 7/16-14 X 2 3/4 zinc, grade 12 I've researched a bit here and found an old thread from way back where there was speculation that the grade 12 bolt is too brittle. People were replacing them with grade 8 and 9 bolts. I'm going to see if I can find the time to go to a Fastenal store and see what they have, or I may just order the bolts that Al at American Sport Bike has. They are grade 9 replacements of the same dimension. they are hex head bolts. The local stores I went to have 2 1/2" or 3" but not 2 3/4". I did manage to buy the left-hand threaded drill bit set made exactly for getting out broken studs. Got it at Harbor Freight tools for $9.99 USD. I also picked up an indexed set of center punches. You select the correct size for the hole the stud broke off in and the punch will fit into the hole. It automatically centers the punch when you rap it. I don't know if I'll be able to dent the grade twelve that is broken off in there but I'll give it a try. I'm told that I need to soak it in something to loosen the corrosion first and then give it a good rap with a punch to loosen the mating surface before using the left-hand drill bit to extract it. | |||

Jramsey |

http://www.allensfasteners.com/search_results.asp? txtsearchParamCat=73 | |||

Buellistic |

Just if done properly about any FASTENER can be shortened !!! | |||

Blks1l |

I just bought some of the F911 fasteners from Allens fasteners as well for the same installation. They are the same as the OEM, which worried me a litle because of all of the issues, but I pulled mine to reseal the top end, not because anything broke. Let me see if I have an extra mount with the airbox mount. In the picture do the heads of the bolts say F911? Mine didn't have the integrated washers like yours appears to have. (Message edited by Blks1l on June 19, 2012) (Message edited by Blks1l on June 19, 2012) | |||

Jim2 |

Yes, the bolts to day F911 on the head. The washers are not integrated as they appear to be. | |||

Buellistic |

What breaks FASTENERS is IMPROPER INSTALLATION in setting up, applying of torque'ing compound and IMPROPER TORQUE'ing !!! | |||

Brother_in_buells |

Speaking about F911 bolts!  http://www.badweatherbikers.com/buell/messages/384 2/220504.html | |||

Buellistic |

"YES", "THE DEVIL IS IN THE DETAILS !!!" | |||

Jim2 |

Today I was able to extract the broken mount stud. It was such a joyous occasion the sky lit up with Fireworks!!!   This is the broken stud and the extractor bit I bought from American Sport Bike . I highly recommend this extractor.  I used the transfer punch and left handed drill bit set I bough from Harbor Freight Tools.  The punch set is nice because you select the size that fits inside the hole and it has a cone shaped tip that will automatically end up in the center of the bolt.  The only problem is this punch set wasn't really strong enough for the F911 bolt. That tip stared out as a nice point. It left a nice mark that showed me where center was but I don't think it left a dent in the bolt. Hitting with the punch does serve to help loosen the bond of corrosion so it wasn't a lost cause. I had also soaked it in PB Blaster over night. The first hole I stared was the smallest bit I had. I managed to drill what looked like dead center to start. After I shattered the first tiny bit I went up a few sizes. I did this several times, oiling the bit every couple of minutes as I went along. Each time I went up a size the hole moved slightly towards the edge a little more off center. I was starting to get worried but not to the point of panic just yet. I kept hoping that the bit would bit in and spin the broken stud free but it didn't happen. I was trying to drill deeper but it seamed that after 3/8" deep it just wasn't cutting at the tip anymore. When I got to the size that was just one size below the 1/4" size recommended for the extractor, I decided to see if it was big enough to fit the extractor in. It was barely, so I gave it a light tap and it really seemed to bite good. So I put the wrench on it and the broken stud end turned free with no problem. I could have saved an hour of drilling if I had just not tried to go so deep. I highly recommend the extractor bit.  Here is the old and new motor mounts.  I ordered the part number from the 2002 M2 parts catalog. The number is L0149.CB and as you can see the new part has a totally different cut for where the factory airbox attaches. The original part has about 1/2" more material and two screw holes that orient vertically down into the mount. The new part has one single hole that is horizontal. The screw will have to go thru the back plate and into the new mount. The drawing in the parts book looks just like the original and NOT like the new part. We'll see how it goes when I get back to assembly. | |||

Buellistic |

Jim2: Good to hear the broken bolt piece came out ... "PLEASE" send me your pictures ... You are now the BUELLer with the correct "BROKEN MOTOR MOUNT BOLT EXTRACTION PLAN" !!! "AND" SOME OF THIS "INFO" WORKS ON BROKEN EXHAUST HEADER STUDS !!! | |||

Jim2 |

I forgot to mention that I couldn't have done it with the cylinder head in the bike without this right angle drill adapter. I borrowed this from a friend. Now they sell close-quarters drills that will do the job of getting into small spaces.  | |||

Buellistic |

IF YOU CAN NOT IMPROVISE AND THINK OUT OF THE BOX YOU WILL NEVER BE A "MECHANIC" !!! Jim2, you are doing just fine !!! | |||

Jim2 |

So very nice to be back on the road again  | |||

89rs1200 |

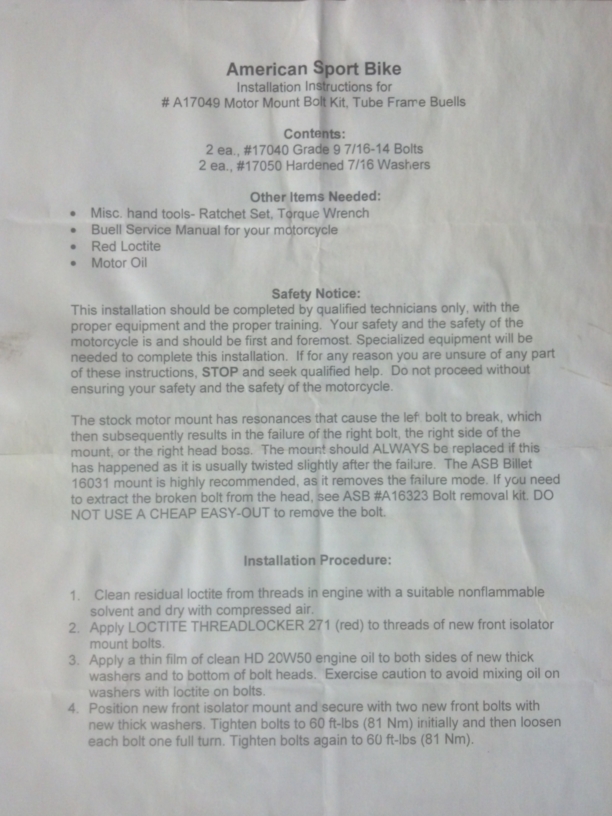

Motor Mount Bolt Kit instructions from American Sport Bike;  | |||

89rs1200 |

Motor_Mount_Bolt_Kit-Buell_Recall_B018.pdf

|