| Author | Message | ||

Eshardball |

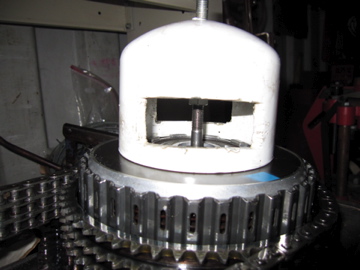

Since I have gotten several contacts on the subject, I figured I would share my McGiver tool with my fellow Badwebbers. Please be advised that this was Cyclonecharlie's idea that I pirated. Materials are 1 3" PVC cap, 1 5/16 X 2.5fine thread bolt, 1 washer and 3 nuts also 5/16 fine. Charlie did his without any welding although I'm not sure how. I wanted to leave enough room to be able to remove and install the Spring retainer & snap ring without too much difficulty   | ||

Fasted |

thanks for the pix and info......again | ||

Ebutch |

Nice to Know!!!  | ||

Cyclonecharlie |

Eric, Now I see why you made the shaft, my cap was flat on top. Also I cut mine all the way down(across the bottom)Either way, good job.Money in your pocket.  | ||

Eshardball |

Beats the hell out of $70-80 for the specialty tool that will live most of its days in the bottom drawer of my tool box. It should work on my Road king too | ||

Ft_bstrd |

I've got one I'll lend out if anyone needs one. | ||

Buell_bert |

OK I built my own version of the clutch spring compression tool and it works super. I have the engine sprocket nut off also but what do you hold on to to get the left hand mainshaft nut loose. I am almost there. | ||

Buellistic |

BUELL_bert: Pictures, "PLEASE" of clutch tool ... | ||

Buell_bert |

Buellistic I took pics but I don't think I know how to shrink them to post them. Send me a PM and I'll send them to you. OK. It's actually close to what is posted here but still works great. I welded 2 nuts to the head of the 5/16 bolt and I used one that was 1 5/16 long. I screw the 2welded nuts to the adjuster then slip the pvc over and put another nut and washer and tighten it up till I can get the seat pushed in to get at the snap ring. (Message edited by Buell_Bert on August 27, 2010) (Message edited by Buell_Bert on August 27, 2010) (Message edited by Buell_Bert on August 27, 2010) | ||

Fahren |

Buell_Bert, I'll send you a pm so you can send them to me and I will shrink to fit and post. -Chris | ||

Jim2 |

Buell_bert, I think your supposed to use the locking tool between the main shaft and the clutch hub before you remove the clutch pack in order to remove the main shaft left-hand thread nut. I locked the transmission in fifth and put a wooden dowel in the wheel spokes and against the swingarm. I made my own locking tool. Buy an electric lawn edger blade from any hardware store and cut it to 4 1/8". This is the plain square blade. You now have a locking tool. | ||

Buell_bert |

Jim2 I made a locking tool last night and it is just shy of 4 1/2" long 1 1/4" wide and 3/16 thick steel. Also I kinda figured I may have to stick something between the spokes too. I'll go out and grab a 2x4. Damn at least I have not wrecked anything yet. | ||

Cyclonecharlie |

James, You got the cart before the horse,you need to put your clutch pack back in so your locking tool will work. But you can do whatever you need to do to the clutch pack first. Now if you have some old plates laying around (that your not going to use for anything) You can bolt two steels and a fiber together and use that to lock your inner and outer hubs together. And you will have made another special tool. Aint this fun.  | ||

Buell_bert |

Well I used the 2x4 and got it off. The clip/retainer was gone when I pulled the clutch drum so at least tomorrow I can get the clip and start putting it back together. Damn in another 50 years I may not even need the manual. The clutch spring tool works just fine also, so thanks for all the help. Lets see what else I can break next week. Also the clip cost is .70 cents what a part to take you down. And they did not even have it. (Message edited by Buell_Bert on August 27, 2010) | ||

Fahren |

Here are Buell_bert's pix:    | ||

Eshardball |

For what ts worth, I used Aluminum flat stock to make the locking tool so that the tool would distort before causing any damage to the sprocket teeth on either the crank pulley or clutch drum | ||

V74 |

where do you get that plastic cap from as i want to take the spring plate out soon ??? | ||

Eshardball |

Home Depot or Lowes. If not, any hardware store that handles drainage pipe should be able to help you out. Its just a sch 40 cap. Nuthin special | ||

V74 |

thanks, i am in the uk,so hope i can get the same over here, | ||

Jos51700 |

That's a lot of work. Ever heard of a couple c-clamps and some scrap lumber? Or welding vise-grips? | ||

Buell_bert |

Hey thanks Fahren for posting the pics and yes my camera sucks. Jos51700 I'ld like to see pics please how you compress the spring plate on your Buell with the C-clamps and wood or the welding Vise Grips. Do you have enough room to access the clip for removal and reinstallation? I do know that the manual says to only compress it enough to get the clip off and no more to avoid distorting it. I think I'll go work on the Jeep now. And YES it is a Eshardball knockoff He deserves all the glory. Thank you. (Message edited by Buell_Bert on September 02, 2010) | ||

Eshardball |

I would imagine that its like watching someone use the set of 3 individual spring compressors on a Mcpherson strut. I have a set that I have offered to more than one person on the condition that I get to watch them try use them. At least there would be someone around to call 911 when things got ugly | ||

Buell_bert |

Yea Eshardball I remember changing front springs on a 76 or 77 Trans Am, Smokey and the Bandit type. I really thought the wife was going to get to use that life insurance policy after all. I did not have the correct tool but we got it done. The good news is I get to still pay the premiums and we are still together. | ||

Jos51700 |

I just always found it faster ( and more thorough ) to zip off the whole primary drive and change a clutch on the bench (disconnect the battery first, of course). Trying to work through the spring compressor was always a PITA, for me anyways... But, I always use the opportunity to clean, loctite, and re-torque the front sprocket nut, so I'm halfway there anyway. |