| Author | Message | ||

Rickie_d |

I have put 4 & 6 pot calipers on the front of a Blast, but never blasted the back of a Vtwin. Check your MS & caliper piston ratios on that conversion! (Message edited by Rickie_d on February 12, 2010) | ||

Rickie_d |

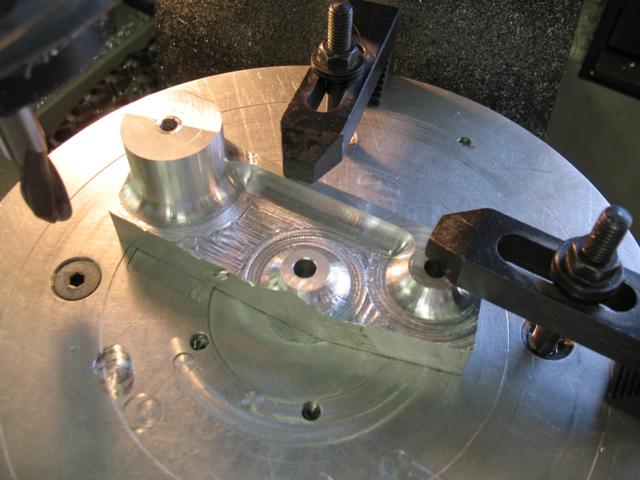

I machined the tubing inserts that will be the treaded attachment point for the axel/adjuster blocks.  Cut the insert end radiuses transferred to the blocks so when in their slots they butt up to the block.   Blocks have been rough faced to a dimension for the additional detail cuts. Before I start to add the trellis work; I will fit the block to a wheel with spacers, caliper, rotor, and pulley to ensure I have not missed some interference somewhere. Then make any adjustments as necessary.   | ||

Rickie_d |

I got to spend some time in the shop this weekend and the axel blocks started to take shape and lost a little weight There are a couple of more cuts to be made and they will be as far as I need them to be for now. I need to plane the back of the tubing inserts and make the accommodation for the brake anchor, then on the tubing. Humm, maybe I will run the rear brake line inside the swing arm tubing like I have in a couple of past projects.   | ||

Blks1l |

Rickie d that is great looking, are you doing that all manually? | ||

Rickie_d |

Yes, I do not even have DRO’s! Got to get me one someday…maybe on the next machine. | ||

Jramsey |

After 30 years of dials and the last 6 with DRO's I'd just about quit before I'd go back to only dials and digie on a stick. Cuts time in half or better. | ||

Rickie_d |

JR - DRO’s would be nice, but for my little home shop making one off parts for myself it is not a priority, especially when the complexity is not that difficult most of the time. It is the setups that are the killer of time, but then I work for myself!  More to come…. | ||

Brinnutz |

Where's the updates Rickie? I need the fix LOL! | ||

Kmbuell |

Sadly, Rickie_d no longer exists. Froggy killed him! At his request. Cause of death seems to be a lack of sense of humor on some members part. Kevin | ||

Brinnutz |

Well that isn't good...So, does anyone have his email? I'd like to keep in touch and follow his work... | ||

Fahren |

send him a pm - his profile is still up. I just did. | ||

Brinnutz |

LOL, I did that after I posted...doh | ||

The_italian_job |

that doesn't surprise me... | ||

Hootowl |

He changed his user name, he's not gone. | ||

D_bag |

Job – Happy to disappoint you …. Hootowl is right, I just switched my user name, the rest of the story is: Someone called me D_bag and to show my sense of humor I adopted it as I thought it was funny. Then one of the admin’s got their undies in a wad over some noise from whiners plus the whole multiple user name thing, so I told him to fix it if it bothered him I am only using this one. So he did, I am now proudly flying the flag of D_Bag. Brin – I have been working on it and have updates, but some family stuff has kept me running too much this week; and I am chasing some rabbits down holes elsewhere. I think that I will have the swing arm to the point where I can remove it from the jig by the end of the weekend. I shaved over 6.5 lbs. off each of those axel plates so far and there is more to go! I think I will wait until I can take that pic without the jig to post, then I will start on the caliper bracket. Rick | ||

V74 |

hi rickie d, great posts, have you seen the latest streetfighter mag issue 194 april,pages 96 to 99 ? kawasaki gpz1100 with one off swingarm incorporating oil tank and push type shock placed under engine compressed by linkages from swingarm and under engine, hate to say this because its looking great but scrap that swingarm and make one with oil contained within it and push type shock??? bet someone send me abusive reply but think of the challenge | ||

D_bag |

V74 - I will have to check the bike out…I am willing to bet they stretched the swing arm and that made it a little easer to package. When I first started to layout this bike I wanted a trellis swing arm with an oil tank built-in with fuel where the oil tank & battery reside; pushing the battery and electrics where the fuel cell would normally be. What became the tipping point for the oil tank location was the capacity I wanted for the S& S engine that will be this bike. I wanted a minimum of an additional ¾ of a quart of oil which I thought would detract from such short airy swing arm, so thing got moved around to support the current custom oil tank & location. I once had a drag racer come to me that wanted to hide his nitrous tank pumps and solenoids; we put all the nitrous related stuff in the oil tank with some of the bikes electrics. Then we were going to put the oil in the rear fender, but with the various sizes of tires he ran based on street, strip, or class we scrapped that idea. We decided to split the fuel tank and build the oil tank in the center third with a filler under the instrument panel. Then we put the battery horizontal under the swing arm pivot just behind the trans mount. There have been so many creative combinations of packaging components; it is just a matter of priority that determines where things end up when laying out a custom bike. | ||

D_bag |

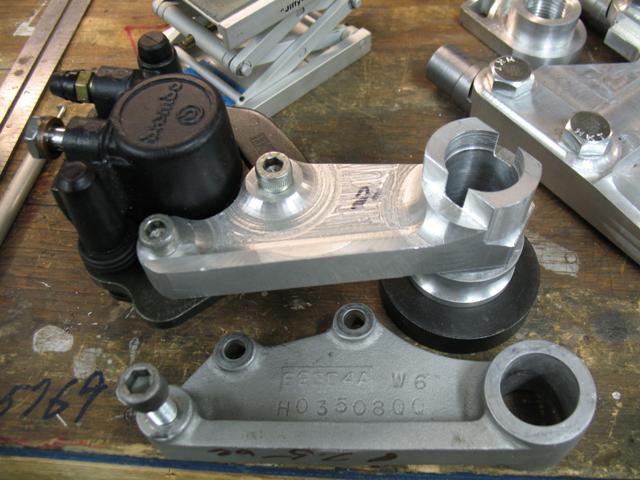

Well, I had the axel plates roughed out and was ready to start with the connection between the axel plates and the pivot; I was studying my next steps and the brake caliper bracket was bothering me, I needed to work out the aesthetics and practical index of the caliper. I tried laying it out with the caliper indexed off one of the tubeing bungs and I did not like how it cut up the look of the axel plate, so I swung in down under the plate to contemplate what I would have to do to anchor it.   I decided to use a custom trick of using the axel slot for anchoring the bracket so I transferred the three constants to a block of aluminum to start carving out what I needed.       Made the bridge connectons from the pivot to the axel plates within the upper and lower limits I had set for belt clearance and set the mounting brace to tie the loops and pivot together.  Fitting the trellis bracing  Initial fitting of the swing arm to the mounting block required some clearance of the block, but it was nothing more than I had expected. So here she is back on the floor.     It is not done yet, but close enough that I can move on to building the bodywork this weekend. (Message edited by d_bag on March 12, 2010) | ||

Road_thing |

Amazing work, Rickie (I mean, D_Bag!). Couple of questions: 1) Are you concerned that torque on the brake arm through those tabs might damage the aluminum in the axle slot of the swing arm? 2) Would it have been easier (or even possible) to simply weld some tabs on the stock caliper carrier then machine away the excess material? I'm thinking the stock carrier is a cast piece--maybe not appropriate for welding? I really enjoy following your projects! rt | ||

Buellfighter |

Man, that looks badass!! | ||

Scott_in_nh |

Wow somebody has been busy! Looks great - you aren't going to use that ugly Sportster pulley are you?  | ||

Ztferrari |

You sir, are a metal artist. roadthing, none of us actually use the back brake! | ||

Purpony |

looking good. Im using the same idea for the brake caliper. Machining it to fit into the axle slot. Coming out great. | ||

Brinnutz |

Bad ass. I want LOL... | ||

D_bag |

RT It is a .600 deep slot and four .500 bracket contact points with no slop to induce hammering of the shelves to deform them. The thing of more concern might be the torque induced through the arm to the anchor as it exists; as opposed to having support closer to the caliper itself. I have done this before without issues, but I am not much of a big rear braker. With that said, and to your point; that is exactly why I never finish the setups all the way through until the bike is completely mocked up and even test rode in the raw sometimes. I never know when or what might change my mind and something like that bracket hits the scrap pile. The thing is, I can still add a groove to the back of the lower tubing attachment point and add a tongue to the bracket to ride in it like an inverted version of the original buell part, but if I do I will machine a new bracket with the accommodation for that design. Just like repairing engine cases, you can weld something like that easily. Scott_in_nh - >>>>Looks great - you aren't going to use that ugly Sportster pulley are Absolutely not!!!! I actually want one of those after market solid aluminum units in the sportster configuration so I don’t have to work around the existing holes. Hopefully I can find one at an upcoming swap meet. If I do not find one before I start on that part, I have a draft of a pattern that looks like the rotor carrier. Ztferrari – thanks! I consider them “coaster brakes”! Purpony - BTW, that stock bracket was 7.5 oz & the replacement weighed in at 6.6 oz (Message edited by d_bag on March 12, 2010) | ||

Phelan |

That is some sick #%^+. you would have to be a D_bag to even post that!  Looks amazing. I want one. But I would want it to use an XB axle since I have XB wheels. | ||

Texastechx1 |

a trellis swing arm on a tuber... the way it should have been done from the factory.  | ||

Maru |

The thought and effort you put into your work is "amazing." I know that word has already been used in this thread over and over Ricky, but I can not think of a better on to use. Steve | ||

Maru |

I just noticed the extra Rotor and caliper on the front. | ||

Road_thing |

Rickie--"no slop"--gotcha. I was thinking in terms of my metal projects, where I try to achieve tolerances more suitable for a framing carpenter... I wondered about moving the anchor all the way in to the axle as well but in real life a stock S2 rear brake probably isn't strong enough to put much torque on it anyway. I don't use mine much, either, except to hold the bike on a hill or something like that. However, there is one gross inaccuracy in your post. You stated "you can weld something like that easily". That should read "any competent welder can weld something like that easily." If "i" tried to weld that, it would look like a big chunk of aluminum bubble gum! Nice. Can't wait to see more. rt |