| Author | Message | ||

Rickie_d |

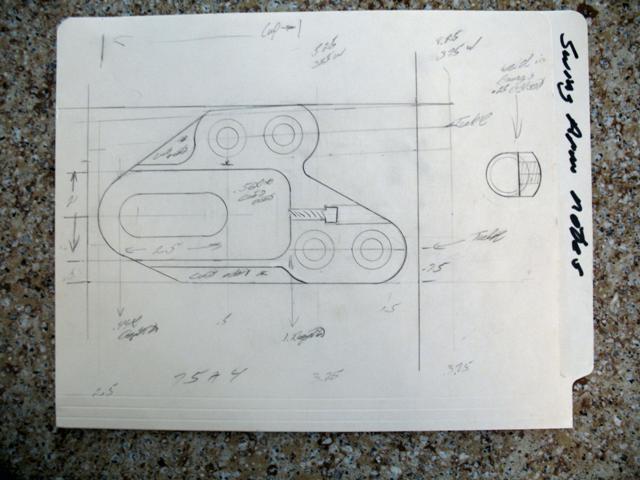

So, for those of you that were interested in the swing arm I planned for the S&M 2, I had some time this week to rough draft the machined axel adjusters.  Then used the cutout taped to the swing arm jig with a couple pieces of tubing added to get a feel for the outline and layout.  | ||

Backnblack |

I will pay for a tuber swingarm for my S1. | ||

Guell |

Yea, me too if you were interested in making them | ||

Brinnutz |

Glad I wasn't the first to ask. But I'd be in for one! lol | ||

Skntpig |

Let the man make it first. Geeez And then make 10 more...One for me | ||

Rickie_d |

So far, this exercise is in the planning stage to identify materials and process to build this particular swing arm. I just established the stock I planned to use for the axel adjusters was inadequate and ordered more material. Once it is done and the process is refined I can give you guys a better idea of what it would cost to replicate. I know one thing is that it won’t be cheap, but it will be cheaper than this one would be if I was charging someone. Good thing I can cut myself some slack when I work for me.  | ||

Road_thing |

I tried working for me but the boss was an •••••••... Great stuff, Rickie--wish I lived closer to you! rt | ||

Rickie_d |

Thanks RT - There are days out in the shop that it’s like watching Paul Tuttle Sr. abuse Jr.. The only difference is I am the only one there! I would shit-can myself, but then who would do the work. | ||

Bluzm2 |

Rickie, I gotta get over to your place one of these days! | ||

Rickie_d |

Call first to see if my boss will let me chat for a bit. | ||

Road_thing |

I guess everybody has those days, Rickie! I often ask myself "Who told you that you're qualified to own tools?" rt | ||

Rickie_d |

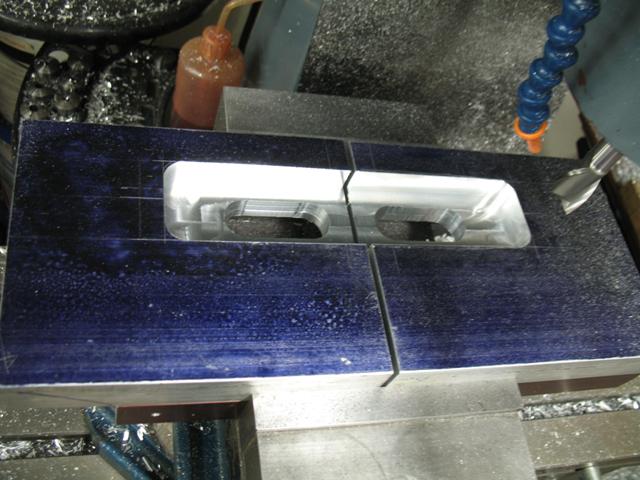

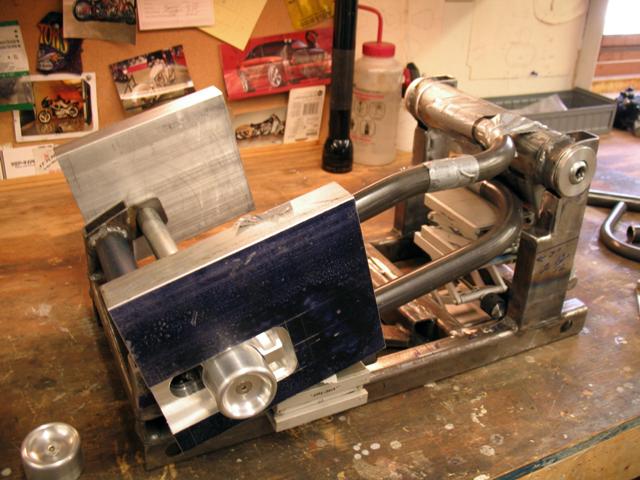

Started carving out the 7.5lb blocks of AL2 that will become the axel/adjusted blocks.   Then mounted the blocks in the jig and mock up the tubing pieces to get a feel for the look.    When content with the layout, transfer the tube angles to the blocks for machining of attachment points.   Found some time today to whittle out last weeks measurements. | ||

Bluzm2 |

Rickie, In the last photo on the right side it appears you have a couple of scissor lifts stacked on top of each other. What kind are they? I need to pick one up, I've not seen that type before. How much were they? Is that type better than the type you normally see? Brad | ||

Rickie_d |

Brad – They are in the last three Pictures supporting the tubing. Those are Laboratory jacks used for supporting experiment apparatus. I use various types of lab support equipment to act as an extra hand when mocking up parts. The units I have are 3.5 X 3.25 base units made by Cole Parmer They come in several size and capacities; VWR is a good reference for specifications… http://vwrlabshop.com/vwr-heavy-duty-support-jacks /p/0031297/search/lab%20jacks/search/lab%20jacks/ Ebay can me a good source for buying the product at a fraction of the cost… http://shop.ebay.com/?_from=R40&_trksid=p3907.m38. l1313&_nkw=lab+jacks&_sacat=See-All-Categories | ||

Bluzm2 |

Rickie, Thanks for info, I'd have never thought of lab jacks. Perfect for your applications. I may have to pick up a couple for fab type work. Right now I need a bit heavier duty one for use on the cycle table lift. I will get some to the lab jacks off flea bay though. | ||

Okimted |

That looks very interesting, would it fit any tuber, say x1, or s3t? would you consider making one for a bike in Canada? If so I'd take one. | ||

Rickie_d |

Ted – The jig was set up with the latter aluminum swing arm and marked with its interference points with say the belt operating ranges. Both of the factory steel swing arms fit inside the range limits of the AL2 unit and so does the one I am building. So it will work on any tuber with Nissin or Brembo brakes, however no inner fender will work with my swingarm…I plan to make my own. | ||

Faseljd |

I own a Blast but this is usually the first topic I check to view what you guys make next. I am in awe of your talents and the stuff you guys make is too cool. | ||

Rickie_d |

Brad - I think you are looking for something like this... http://www.dragspecialties.com/fatbook/13/144/7740521?q=fat%20jack But, I just use these 5 buck junk yard jacks as my lift accessory jack...  (Message edited by Rickie_d on February 10, 2010) | ||

Maru |

Rickie, will your swingarm be using a belt or does it require a chain? | ||

Rickie_d |

Maru - The design parameters encompass the utilization of stock components such as the belt, pulley, spacers, brakes (early or late), and frame (early or late tube). It requires the use of an early swing arm core and axel with late AL2 adjusters…. With that said you can convert it to chain, but need to consideration the more aggressive “whip action” and utilization of skid pads added to the swing arm much like dirt bikes (or tards) with long travel suspensions to prevent gouging of the unit. Until I actually mount this swing arm in that application, I will not know if there are issues. (Message edited by Rickie_d on February 10, 2010) | ||

Buellfighter |

Nice work Rickie, I'll be checking in to see your progress. I'd sport a tuber swingarm! | ||

Rickie_d |

By the end of this weekend I should have the time to connect all the dots so you get a feel for the end result... | ||

Bluzm2 |

Rickie, That's the type I'm looking for but I'm sure not buying one for $275! Yikes, are they gold plated? I too have a couple of the car types, they work for a lot of different things but I frequently have need for a flat top surface. I've tried modifying a car type with somewhat limited success. I've seen ones simular to the DS unit above on Ebay for around $100 or so. Maybe I'll just keep tweaking the car type until I get it right.. | ||

Davefl |

Bluz, will the ones on the bottom of this link work. http://www.discountramps.com/motorcycle-lift.htm | ||

Bluzm2 |

Dave, That is exactly what I was looking for, cheaper than fleabay too! Thanks much for the link. Brad | ||

Jayvee |

Hey, can one of you billet makers come up with a bracket to adapt a BLAST two-piston Front Brake to work as the REAR Brake for an M2 (tubers)? The Blast brake can be had for $25 bucks on eBay, and a bracket shouldn't cost more than $40 - $50 to make, but the 'kit' could be sold (to me, for example) for $100 - $145-ish? See this one listed at $380 for comparison: x-race.net/Neuer-Ordner/alle-seiten/4_kolben_brems sattel_inkl.htm Looks like a easy money-maker for somebody like Precision Engineering ! (Message edited by jayvee on February 11, 2010) | ||

Road_thing |

..."to prevent gouging of the unit." I will go to great lengths to avoid gouging my unit... rt | ||

Rickie_d |

RT - I hate it when that happens...The last time I gouged my unit, I was playing with a "tard" I have to go shave some more metal from my swing arm!!! | ||

Outdoors |

JV, The idea of fitting a Blast two piston rear caliper to a tuber sounds interesting. Any of you metal artists interested??? |