| Author | Message | ||

Ourdee |

Build shed on rails with steel wheels. I have been planning on doing it to my swing on a small deck. The deck will be able to move out of the way and for mowing. | ||

Greg_e |

OK, let's start with the bad parts: It smells, kind of like all the rubber stuff from Harbor Freight. The low pressure gas hose has some kind of sticky goo all over it, and it's loose on both the flow meter and on the welder. The instructions can be a little misleading. They say for AC welding you can connect it like you are DC welding and it will not affect the weld, and you can switch to DC without swapping the cables. So like an idiot, I did that and promptly melted the tungsten to a huge ball. They failed to say that if you do this, "invert" the cleaning setting. Had way too much current going into the tungsten. My 25 foot extension cable needs to be about 15 feet longer. The torch pretty much sucks, glad I bought a parts kit with extra pieces to fit in my torch body. The collets are rough which is the biggest issue I have with it. The on/off torch control is going to make aluminum very tricky, need a foot pedal or to greatly refine my settings and probably preheat everything. I need a lot more scraps to practice on, lots and lots. Now the good parts: It melts metal!  All the settings seem to work, frequency, pulse, etc. Haven't tried DC mode, haven't tried arc mode, but I bet they work. HF start never failed, but it certainly isn't as crisp as what I've been seeing on youtube from higher end welders. Some of it might have been metal prep. (or the lack of prep). Overall, this looks like it should be a good machine, hopefully it stays working for a good long time. Mine was made in 2012 so I can see why they are being discounted so much. For getting into it for about $1000 for everything, not too bad. | ||

Sifo |

Good to hear things are pretty much working. Again, I'm no expert, but it's hard for me to imagine welding aluminum without a foot pedal, or a variable control on the torch. I'm sure there are probably tricks that can help, but on the stuff I've done, it changes real fast as it starts dumping heat into the aluminum. | ||

Greg_e |

Yeah. My new plan is to weld in short lengths and move on to another part of the assembly. That is 1/16th 6061 above at 40 amps, even the ramp down to 15 does a lot of heating once it is really hot. A bigger thermal mass would help too, but things that big are not scraps to me but usable stock. Need to shorten my ramp down time from 5 to about 2 seconds which should help when a runaway starts to happen. Sum total, I have about 10 minutes of actual arc time, need lots more time. Also need to prepare all of my tungstens for an easier swap when I dip one which happens fairly regularly right now (as expected). I bought a sharpener on ebay that attaches to popular hand held motor tools, need to get that attached and see how it works. | ||

Ourdee |

when I dip one which happens fairly regularly right now Practice will help. Check how you are supporting your welding hand. | ||

Bandm |

When I weld aluminum I use firebrick on the table, metal tables suck an amazing amount of heat out of the workpiece. | ||

Greg_e |

I'm going to make a torch mounted variable control. It's a simple resistor control with 0 ohms being no current, and around 10k ohms being max current. Wish is was reversed, then I could use a simple pressure gauge to regulate the current. Have to keep looking for a better solution, but sometime next week I should be able to have an amperage control of some sort. The couple of times I messed up the tungsten, it was sticking the filler in too far. Need lots of practice and I'm guessing I use up 80cf of gas before I'm even ready to weld a real project, good thing it is only $30 to refill/exchange. | ||

Ourdee |

Biggest tricks to the art: Muscle memory through practice. Recognizing what happened just prior to the incident. As long as you have a clue and determination you will become a good welder. My goal was always to eclipse the teacher. After you get good, have someone you consider a good welder watch you weld and comment. | ||

Fast1075 |

You may already know, but for preparation on aluminum, use only a stainless steel wire brush. A dedicated brush that you use only for prepping aluminum. | ||

Greg_e |

watch the second half of this about the reason for using dedicated brushes https://www.youtube.com/watch?v=FraGLyZUueM | ||

Sifo |

It wouldn't hurt to play around running beads on steel for a while. It will keep the cost of "scrap" lower. The mechanics are close to identical. Once you can run decent beads with steel, the adjustment to doing aluminum isn't that much. If you can make a variable trigger for your torch, make another to put into a foot pedal. That would be a nice "project" to weld too. It doesn't hurt to just run some beads with the torch, focusing on keeping the arc nice and tight. Make sure your torch hand has a good support along it's path. It doesn't hurt to do a quick practice sweep of the torch down it's intended path with no arc. It gives you an idea of how far you can run a bead, while keeping comfortable, and not running into some obstacle with your pinkie, or torch, or torch cable, etc. This becomes even more important as you start trying to weld tubing, or anything where you aren't just going in a straight line. Once you learn to keep the arc tight, and have consistent torch movement, then teach your brain to also focus on dipping the filler rod into the puddle. It sounds simple enough, but it really does take constant concentration on numerous details. BTW, running aluminum without filler will probably result in a cracked weld. If you practice that, just don't freak out, wondering what you did that caused it to crack right down the center of the weld. BTW, if you are over 40, it's likely that a "cheater lens" in your helmet will help you see the puddle much better. If you can't see the details, you just can't get good with a TIG welder. My welding took a big positive step when I started using a cheater lens. | ||

Bandm |

when I dip one which happens fairly regularly right now Walking the Cup https://www.youtube.com/watch?v=HgqIWKn5gr0 | ||

Fast1075 |

I use a good quality auto darkening helmet. Lets you get your head into tight spots that don't allow you to flip the helmet up and down. Makes it much easier. My Miller helmet is fully adjustable for tint, reaction time, and delay off. If you use it in the sun, use a drape over the back, which is a good idea anyways to keep that errant spark from going down your collar. | ||

Greg_e |

Even the cheapo Harbor Freight adjustable auto darkening helmets seem to work pretty well, at least the one I was using works pretty well. Have a Kobalt auto darkening as well, but fixed with a #10 shade. I think I can program it so I can get out when the puddle starts getting wide and just run shorter beads while I wait to create a variable amperage device. A lot of the types of things I do will not be sitting at a table (or sitting at all), so I want to get comfortable with a hand control of some kind. The ones that are currently on the market are pretty expensive and I only saw one that was a pressure sensitive type (little load cell) which is ultimately what I think I might want to build. Press harder for more current seems logical if there is some fluidity in it. Another had fixed values with around 5 steps through the lever, that might work as well. Hot for getting going, medium for once the heat is in, low for resting or getting out of the weld, etc. And if you look closely, one of those disks was without filler, noticed the monster crack all the way through. Knew it was coming, 6061 is pretty crack prone without any filler. Hopefully my book on TIG welding arrived today, I've scoured about all I can from the internet (I think). (Message edited by greg_e on September 07, 2018) | ||

Greg_e |

The electrode grinders arrived today, got a 15 degree and 20 degree to put on my motor tool. So far works great and half the time compared to a cutoff wheel. Pretty cheap compared to commercial versions https://www.ebay.com/itm/15-TungstenMate-Tungsten- Electrode-Sharpener-Grinder-TIG-Welding-15DL03/183 297088976 | ||

Zac4mac |

Right now, Chinese diamond abrasives are really cheap and surprisingly good quality. Don't push hard and they will last a long time. Z <edit> I have a lot of carbide burrs for head porting and diamond is necessary to keep them sharp. Some of the finest kit at Harbor Freight. (Message edited by zac4mac on September 07, 2018) | ||

Greg_e |

I planned out enough of a welding cart to start buying materials... Why is it cheaper to buy from half a country away and ship than it is to buy full length pieces at my local metal supply store? Looking at $135+ tax for aluminum angle locally, or about $60 shipped for the same thing from Utah via ebay. Not that hard of a choice, just have to wait a week for the delivery. And yes, I am making the cart out of aluminum. Bought the welder to weld aluminum, need practice, seems logical to me. Can't buy steel locally cheaper than the ebay stuff. | ||

Sifo |

I built my welding cart out of aluminum too. Great practice. Worth the extra expense to get the fabrication experience in aluminum. | ||

Greg_e |

Thanks, that's my thought. If I wanted a steel cart, I could just use my fluxcore welder. The wheels may cost more than the rest of the cart, good wheels are expensive. | ||

Ourdee |

Look for carts and junk on CraigsList to scrounge wheels off of. I personally like building my carts with Radio-Flyer running gear underneath. | ||

Sifo |

Why is it cheaper to buy from half a country away and ship than it is to buy full length pieces at my local metal supply store? I've purchased from metalsdepot.com in the past with good results. I was just looking for some 304 stainless for a project and priced it out. Shipping killed it though because of the length of what I needed. I priced it today at a local supplier and he beat them by about $75 on what was about $300 from metalsdepot.com. Shipping brought it over $400! Pricing seems all over the place sometimes. It pays to check around. | ||

Nuts4mc |

you can buy some small qtys of metal shapes from McMaster-Carr....but be careful of the shipping $ suggestion...bolt a piece of cold rolled steel on top of your Aluminum table...you can use those magnetic "angles" (like from HF) to help keep projects square. hth | ||

Ourdee |

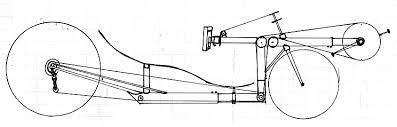

I used to buy from a large supplier that a friend that owned a machine shop set me up with. Most of the tube I was buying came in approximately 22' sticks. One day the supplier was out of a size that was critical to what I was building. A guy that I had befriended in the back gave me a phone number of a race team that had bought out that size tube. I only needed part of a stick in that size. So I called and went to the teams location and was sold what I needed at cost. Getting to know the people that work for the movers and shakers may net you great results when the chips are down. Sharing your project details and letting them think they are the best goes a long way. I call it self fulfilling prophesy. My friend with the machine shop would let me measure and copy parts of their race bikes. He would also tag my metal orders on to his and just charged me his cost.  This was the sketch that I presented to my wife to get funding approved prior to building this lowracer. Working 12 hour shifts at the foundry and building this on the side did not contribute to marital bliss at the time.  The carbon fiber seat has three layers of fabric with two layers of .250" honeycomb nomex sandwiched in. Weighs 6 or 7 ounces. I was making seats out of magnesium prior to this bike.  Greg, I built the wheels on this. Roller brake hubs and a three forward three reverse pattern on the lacing. I think the window film was still attached to the rims used to make the wheels aerodynamic. (faired the spokes) I raced this one at the Major Taylor velodrome and rode it and a high wheeler on the Indianapolis 500 track for Tour De Cure 2005. This bike was welded using oxy acetylene. | ||

Greg_e |

Gas welding seems to take way more skill than I have right now. But from what I've read, 4130 still works best with gas welding as it doesn't really require the heat treat after the welding like you should do with TIG or MIG welding. Something about the larger heat affected zone and the way it cools allows it to come back to temper closer to what the factory put on it. | ||

Etennuly |

Ourdee that is awesome. I watch this thread with great interest. I'm new to TIG and have found being self taught is not going to suffice no matter how many videos I watch. I am a professional MIG operator, steel, aluminum, and stainless, as with stick welding to include cast iron. I learned to weld on oxy acetylene and was very proficient at it. At one time in my late twenties, I oxy acetylene welded some tubing for a buddy on some racing headers . Everybody in the racing community who looked at them asked him when he started TIG welding. This back in the early eighties when TIG was rare outside a factory setting. I loved oxy acetylene welding. I studied as I did it to try to mimic the look of TIG. I put a lot of effort into controlling the heat that I put into the work. I played with more heat moving faster vs less going slower, constantly looking for the narrower heat path while getting the best penetration. I often heard people who did not know say that it would never hold. It always did for me. That is what set my challenge to make it look like TIG. | ||

Greg_e |

I think the biggest issue I'm going to have learning to TIG is lack of scrap metal to burn up. I should have a bunch of material left over from the cart build, and plenty to practice on once the pieces are cut before I try to tack anything together. So far my biggest issue is heat control with just a trigger. For now it looks like I need shorter beads with time between to let it cool a little. Even lower current to the point where it doesn't really get going for several seconds will get to be too much out near the edges. My cart is going to be 1/8 thick 1.5x1.5 angle, if that is too weak I ordered enough to box a few areas and gusset a few others for strength. But I also ordered two large pieces of 1/4 thick 6x12 plates, going to weld into a V for the gas cylinder and then weld to the rest of the cart. That 1/4 will either be difficult or manageable. Won't have the parts to try and build a torch mounted amperage control for a while, the 10k pots that I hope will work won't arrive for a while, neither will the oddball plugs I need to connect them to the welder. (Message edited by greg_e on September 13, 2018) | ||

Ourdee |

I took classes when I was 14. Did Oxy Acetylene and stick for near 33 years. Till Fiat Chrysler Automotive gave me a MIG card. First time I repaired some outer body panels with out warping the body a supervisor came up to me and told me I was a professional now. I told him to get out of the way I had work to do. I've been told that TIG is easy if you can gas weld. | ||

Ourdee |

Greg, I have a challenge for you. | ||

Ourdee |

Oh, Oh, Oh... Here is how to practice. I can MIG the razor blades together. I had to mig weld thinner than that for FCA. Then file the whole surface smooth enough to prime and paint on a class A surface on new cars. Engineering would then video the back sides of my welds and put them in a saved file attached to the VIN and save forever prior to signing off on the car. Then someone had to come in and phosphate the back of my weld. Had to be all metal. No Bondo allowed. The weld on the blades was the usual size of the repairs I made. I did have a 12" long one once. | ||

Greg_e |

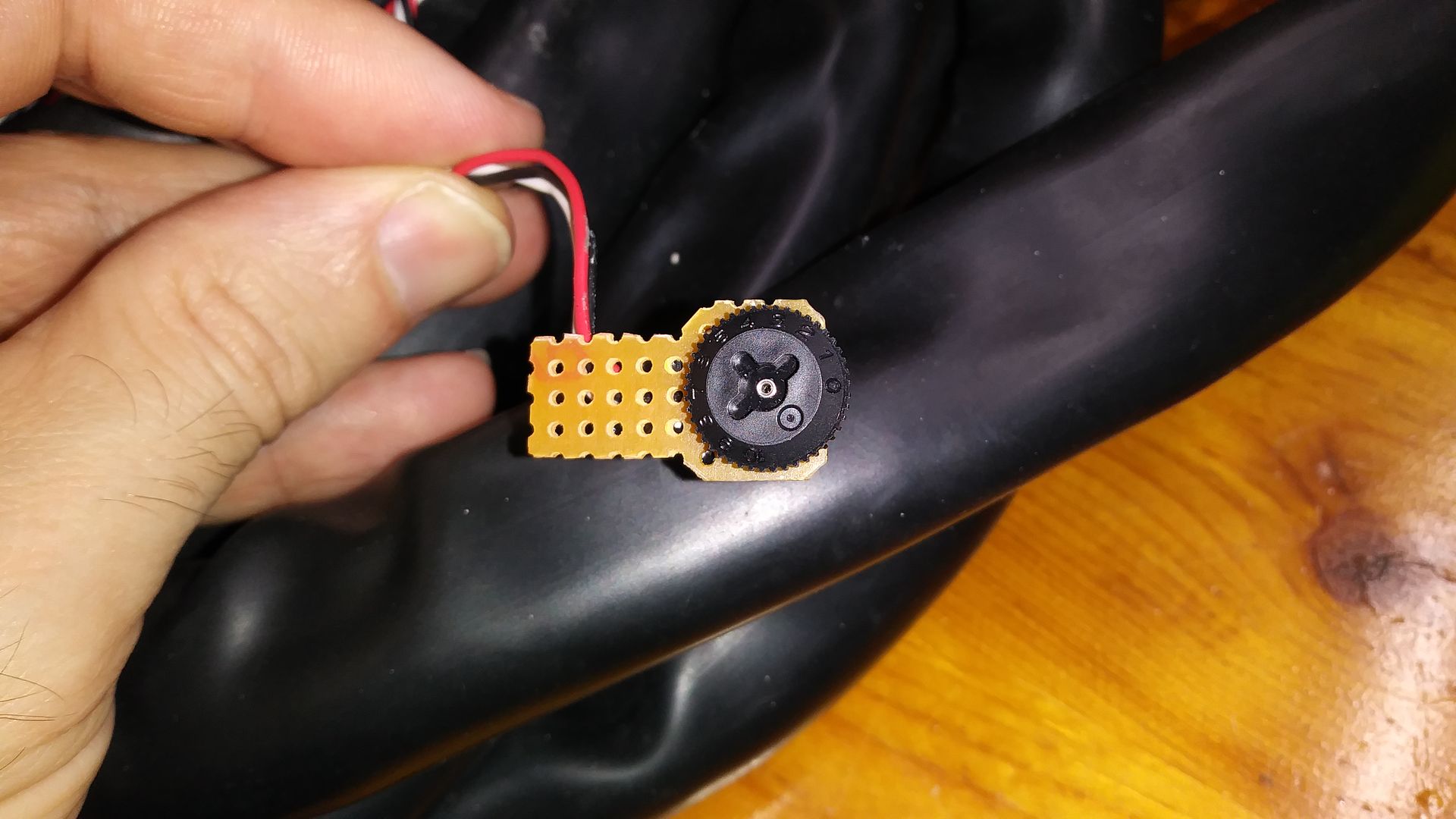

Not sure my TIG will go low enough for cans, lowest it goes in 2t/4t is 20 amps, lowest in variable is 10 amps. But I can pulse and have frequency to 100hz, plus a few other things I need to look up. Had a surprise today... Went looking for that random 10k ohm pot. to test the variable (foot pedal) connection and found something better. Had a couple of 10k ohm thumbwheels that I had forgotten about. Was waiting for some to arrive but now I have a torch mounted control ready for the connectors to arrive:  After a bit more hackery I have this:  Still need to press the switch, but this should get me actually working instead of watching stuff burn through. But I finally got shipping notice on the metal for my cart... Shipped today and won't arrive until around the 20th. Might need to tempt fate and see if I can get a different project machined and welded while I wait for that metal to arrive. |