| Author | Message | ||

Doz |

So I traded one of my 11 bikes for another guys failed attempt at a café project. A bunch of boxes and a promise of "it's all there", and I'm off! The bike is a Honda cx500, apparently this is a popular base to start with and lots of pictures on the internet show some promise. One thing I've noticed on some of the pictures is that the battery is either hidden or not there at all leaving a big gaping hole where the airbox also resided- how'd they do that? | ||

Fast1075 |

There is a lot of cafe' build info available. Google CX500 battery relocate. Several options. The service manager at the local Honda shop built a CX cafe' bike. He put his battery in the seat hump. It came out very nicely. He used Dunstall style exhaust pipes. | ||

Gschuette |

A ballistic 4 cell will start a 650 single without any problem and would be easy to hide. My friend is using a capacitor on his CB cafe project. | ||

Doz |

I'm so-so about the capacitor deal, guess I gotta get up to speed on these new (small) batteries | ||

Reepicheep |

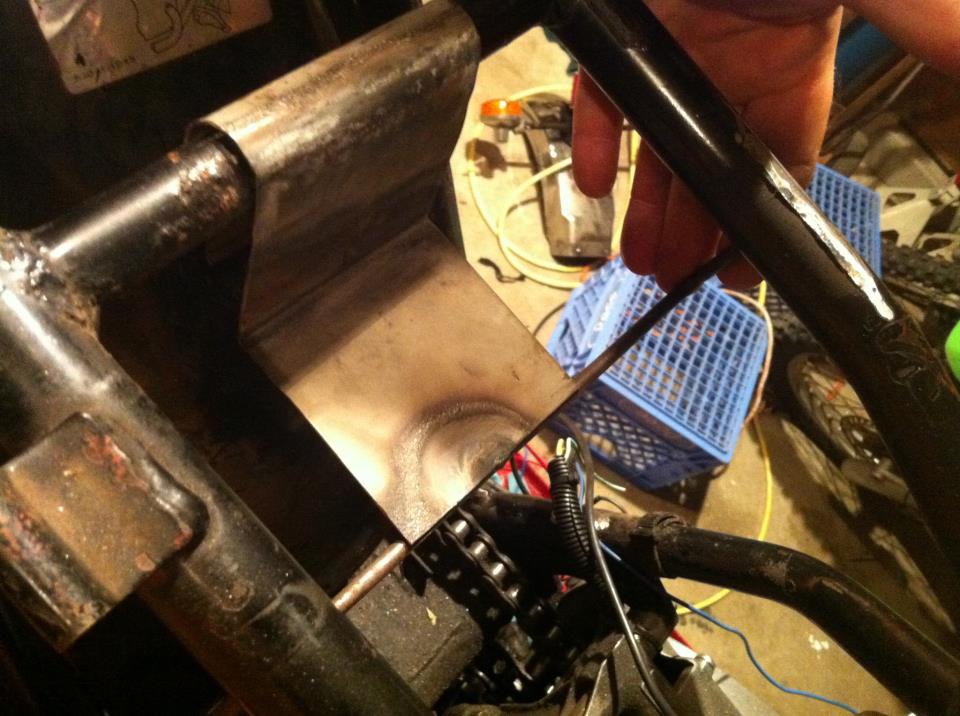

I did it on my KZ400 cafe conversion, it still has a battery, I actually took my old XB battery and put it in there. Long after it won't spin a Uly it will spin a 400cc parallel twin just fine. Here is how I did it...    | ||

Doz |

Nice!, could use some padding though  | ||

Rick_a |

Looks like some OCC spider bike influence there. | ||

Rick_a |

If the wife gets her way we'll have an 80's café bike project going here eventually. After I finally decided on a supermoto to go with, apparently my favorite childhood bike is the only bike both of us can agree on. | ||

Reepicheep |

What it really looks like is me with a lot of steel rod laying around, and a new MIG welder, and a nice long rainy saturday. It was a ton of fun, though not the most time efficient. I'd bend a rod into a spine to get the position just where I wanted it, then weld it in place. Once I had a rough skeleton, I just slapped in webbing to support a seat pan made from heat softened sheets of ABS plastic.    The seat foam was a cut up sleeping pad (which in hindsight was too firm) layered and glued with contact cement and cut with a very sharp knife (electric knife would have worked better but I didn't really need it). The towel was in place of burlap or sissel to hide any imperfections in the foam. The seat cover material was found in a corner at a big chain fabric store and is very nice "motorcycle seat" material. The seat took more time than the engine rebuild. |