| Author | Message | ||

Brumbear |

was posted on another site and maybe you guys have an answer. Why is the front and rear rim a different configuration? I think power transfer and lighter weight on the rear/front but aesthetically both the same would be nicer. | ||

Skntpig |

I'm no engineer but I would guess the forces for braking directed around the edge of the rim along with a bit of lateral flex built in to the front wheel require a very different design than one made for a much heavier tire but designed to put over 100 ft lbs of torque to the ground with most of the force directed at the hub/sprocket/drive. I have no doubt that EBR could have designed matching wheels that would add weight to both and compromise performance. It seems that this was more of an exercise of "Let's build the best performing bike for the money", and trying to maintain the looks of yesterday was secondary. I bet you will find (by talking to the right folks) there are quite a few mini engineering firsts in each of those wheels. Discuss... | ||

Hughlysses |

It's been posted in various threads on Badweb several times. Basically the front and rear wheels do very different things, and therefore have very different stresses and loads. It only makes sense that they are designed differently and look very different when they've been optimized for maximum strength at minimum weight. | ||

Ratbuell |

Form follows function. Design the best front wheel for what a front wheel does. best = light, strong, and correct rigidity in the directions a front wheel with a perimeter brake needs it. Design the best rear wheel for what a rear wheel does. same parameters...but a different set of requirements and thus a different result. Compromise the result on either wheel to make it "look" the same as the other one? Nah...we'll go for the best wheels for the job  | ||

Court |

The wheels are the result of amazing engineering that, eventually, others will catch up with. The front and rear wheels of a motorcycle "see" completely different forces and loading? Some of that, not all of it, is a result of the ZTL braking system. But . . when you see a front and rear wheel that look identical you can be certain that both represent compromises in the pursuit of symmetry. Try rotating the wheels on a Porsche front to rear and see what happens. :-) Anyone can do good. Elves are shooting for the best. It's pretty simple. | ||

Reepicheep |

The ZTL brake allows the potentially massive torsional forces (think doing a stoppie) to be transferred direct from rim to fork without having to traverse the hub, so the front wheel only has to be strong to forces intersecting the hub (for example hitting a curb head on). It doesn't need torsional strength. The rear however, until EBR develops a rim mounted sprocket, still needs torsional strength because the engine power must be transferred through the hub. So from a rolling perspective they are the same, but from a demands perspective, they are very different. (Message edited by reepicheep on October 23, 2013) | ||

Team_ruthless |

So basically the same reason tire size, tread pattern and brake systems differ front to rear. I don't this much buzz about the xb wheels being different. I want to know why the front rotor is slotted only. I think it looks awesome but figure there has got to be a reason behind it. | ||

Hootowl |

The slot lets the gases escape. Holes do not. At least, not on a bike rotor. In a car, where there is a finned gap between the two pad contact areas, holes make sense. The gases can escape into the internal finned area. On a bike, those holes can only lead to the other pad. That doesn't help. | ||

Skntpig |

In some auto racing organizations drilled rotors are outlawed because they can and do crack. Those stock Porsche rotors are a good example. Google cracked drilled rotor It was a good idea but it's old technology now. I'm sure some carbon or carbon ceramic rotors are still drilled but that's a different game all together. | ||

Brumbear |

Thanks guys I'll redirect to this thread. | ||

Blake |

I'd expect the front spoke arrangement will eventually be reconfigured to better match the rear. It will add mass though. Probably not more than can be removed through further refinement. | ||

Mr_grumpy |

I can't see either wheel when I'm on the bike so I'm not bothered. Now if somebody can come up with wheels that keep themselves clean, I might show a little interest. | ||

Hughlysses |

I can't see either wheel when I'm on the bike so I'm not bothered. +1. Also applies to blinkers, reflectors, ugly welds on mufflers, and various other cosmetic complaints. | ||

Pwnzor |

The rash on my fuel tank sits conveniently under my thigh while riding, but I'll be damned if it doesn't disturb me when I'm looking at it from across the garage. Doesn't seem to affect performance at all... go figure. | ||

Crackhead |

"The rear however, until EBR develops a rim mounted sprocket, still needs torsional strength because the engine power must be transferred through the hub." Humm... I wounder if the rear brake could be integrated into the sprocket. Then the torsional forces would be on one side of the rim. Allowing for different spokes within the same rim. | ||

Slaughter |

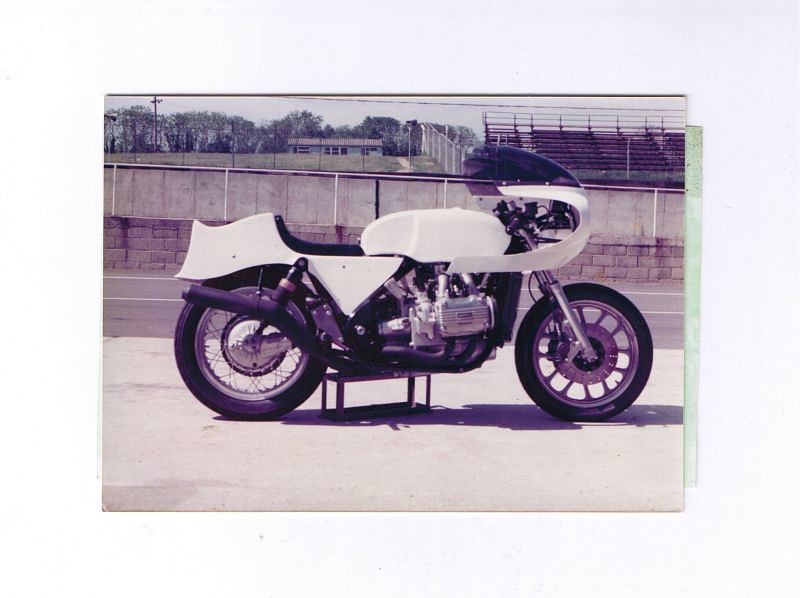

As others have said, consider the function, not the cosmetics. The only Buell with reduced rear spoke mass:  (Message edited by slaughter on October 25, 2013) | ||

Reepicheep |

Nice XB9! | ||

Buellkowski |

Until multiple reviews from mainstream cyclep0rn outlets come in stating that the RX's wheels holds the road better than anything else out there, expect the "why're them rims diffurnt?" observations to proliferate.  | ||

M1combat |

"Humm... I wounder if the rear brake could be integrated into the sprocket. Then the torsional forces would be on one side of the rim. Allowing for different spokes within the same rim." Ehh... Not sure where to start. | ||

Aesquire |

There are rear bicycle wheels built that way. I've seen one side radial, the other 3 cross. It's been common to build bicycle wheels with 3 cross rear, 2 cross or radial front spokes, too. Different jobs, different wheels. I used to run a 36 spoke rear/32 spoke front on my mountain bike. The industry changing from rim brakes to disc on bicycles means that the front has to take forces like the rear does, but in opposite direction, and I've seen wheels built that way too. Most people never notice. You don't see that on cheap Chinese bikes, because the wheel sets are machine made, with a worker feeding the spokes in place in the jig and the spokes being tightened by the machine. | ||

Rocket_in_uk |

Someone mentioned not a lot of fuss about the XB wheels when they came out. Well actually if I remember correctly there was a lot said about them at the time. Erik had come up with a design in particular to the front which allowed for a lighter than usual wheel with unusually thin spokes yet still maintaining great strength to cope with the forces applied. I also remember something about them being made in China as to make them in the US was too expensive. China was the only country capable of manufacturing them at that time at favourable to Buell costs. Carbon fibre is still the way to go though  Rocket in England | ||

Argentcorvid |

they make them for custom/show bikes. I don't think there's any advantages like you are thinking though. https://www.google.com/search?q=motorcycle+sprocke t+brake+disc | ||

Crackhead |

On second thought, the grease/oil from the chain might contaminate the brake pads. But for street bikes using belt drives, based on the size of the CR/R pulley, the rear brake could be integrated into the inside of the pulley with the pulley mounting mid spoke. Blast style. Then the non drive side could be radially constructed and half of the drive side. | ||

Mr_grumpy |

I can just hear the bleats of outrage that you're forced to buy a whole pulley-disc assembly when all you need is a new disc. |