| Author | Message | ||

Lemonchili_x1 |

Hey folks. I figured there is such a broad spread of people on BadWeb that maybe you might be able to help me with some work research. I work for a building controls/building automation company, a BMS or BAS or BMCS company if you're familiar with the industry. Traditionally we, and the industry, have mainly done HVAC control with a little bit of other services, but we are now doing more and more energy monitoring and reporting. For example I've recently finished a small/medium 2 level office building which has over 50 sub-meters in it and about 15 water meters. We monitor and report daily and monthly kWh's and peak kW and all sorts of cute stuff. I'm looking to the future and working out what our metering and monitoring systems features should and/or could be, and what is genuinely useful to the client. Ie what data to collect and how to display it, what alarms to monitor, what reports to generate. Anybody work in the field of energy management for facilities? If you could share any experiences it would be much appreciated. cheers, chili | ||

Kenm123t |

Chili I work in that area re commisioning a Surgery center in the am What type of buildings and tennants and system types | ||

Lemonchili_x1 |

Most of our work is commercial office buildings, low rise and high rise, and for the moment that's what I'm concentrating on. Some are new construction, some are re-furbishment. Generally we are only focusing on the base building energy (HVAC, lighting, lifts, common area systems) for the facility manager, but we have some work on tenant systems happening and I can see more in the future. Usually the sub-meters we install have a modbus interface and we usually monitor (and trend) kW, kVA, kWh, amps, volts, power factor, frequency. We use the data ourselves to improve the efficiency of the HVAC systems. Where and how many sub-meters installed varies from site to site, client to client. A lot of the time we are sub-contracted several layers away from the end client so I'm trying to get a feel for what data they want. Eg kWh/m2 (sq ft) or per occupant, or kg CO2/m2, or are they interested in peak demand, or maybe power factor? We also do some shopping centres(malls), some defence facilities, and a few specialist facilities. | ||

Steeleagle |

I've worked for a manufacturing company (tires) for 12 years as their energy/environmental engineer; 3 years for an architectural/engineering company designing HVAC systems; and for the last 21 years for another company, a government contractor, first in EHS and now back in Facilities. My perception is that MOST companies who claim to be interested in saving "energy" are actually interested in saving "money". The data they will want is that data that reduces their bills, regardless of the actual impact on their consumption. For the tire company, our electric bill was 67% demand, so we looked at KVA and PF. The electric tariff for the company I work for now is heavily based on strictly consumption, so the focus is KWH. KVA has little bearing, ditto PF. Fossil fuels are different from my experiences, and cost for those has always been based on strict consumption, no elements of demand or efficiency existed. (We're talking 30 years ago, too.) So for the tire company, we waffled between using natural gas and #6 fuel oil, based on cost per unit of energy, allowing for the steam-production efficiency differences of each. We monitored energy consumption (in that case in the form of steam produced by our boilers) at close to the equipment level to baseline and track usage patterns in order to help identify abnormal consumption from blowing traps, etc. Yes, we tried to conserve where possible through energy efficiency, insulation, etc., but most of the effort was from monitoring the process and eliminating waste from equipment failures. Still driven by cost. Currently the company I now work for uses relatively little fossil fuels (natural gas only), and it's for comfort heating and humidification. I can't really provide much insight. Reducing actual energy consumption (KWH and BTUs) without capital expenditures is more about behavior control and getting employees/occupants to accept modified consumption strategies. Try turning off lights or using night setback on your HVAC controls, or adjusting setpoints a couple of degrees and people scream from just the "change". I subscribe to "Do you do this at home?" to justify little changes...and sometimes big ones in all areas. (I just spent the last 20 years in EHS, which is directly linked to energy, disguised as "sustainability".) I'd say to get attention you'll need to focus on how their energy consumption affects their wallet, and develop monitoring strategies accordingly. | ||

Fast1075 |

Steeleagle has a firm grip on reality...the sad part is that largely, the most cost effective ways of reducing energy consumption (maintenance and conservation) are at the short end of the profile. We take care of several buildings that have the individual metering systems..the building owners like it because he can bill the tenents based on consumption...the tenents hate it because they have to pay for it. The tenents only care about KW consumption and load peaking (which sets the base rate for the energy). One good idea is to monitor lighting costs, especially if your company also does the retrofitting...just remember the pinheads in capex own the purse strings. | ||

Court |

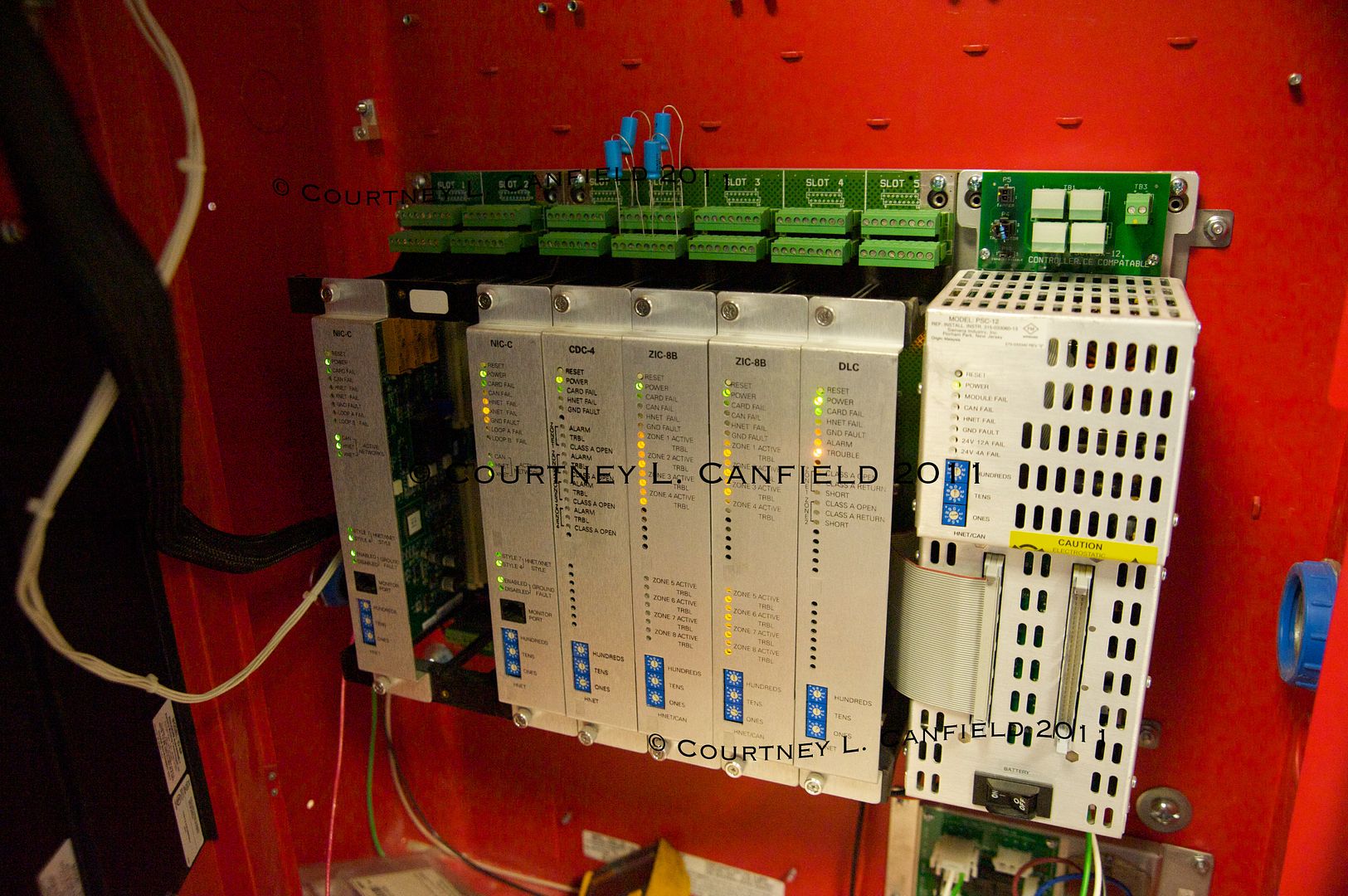

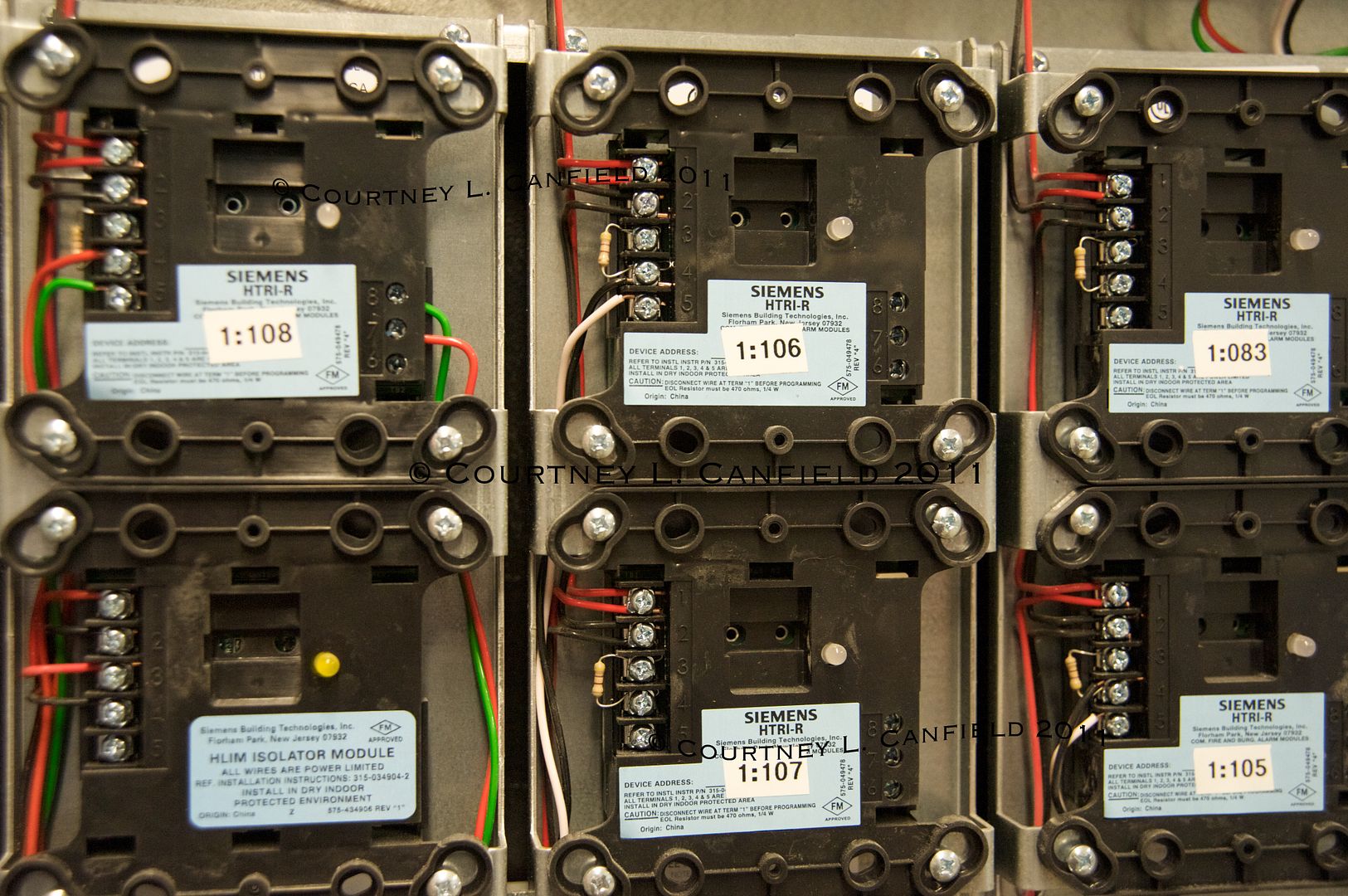

Stuff like this?    | ||

Steeleagle |

That's the NEW stuff! Here's what most have: (That allegedly is a pix of my father's old ham radio station from the 30's or 40'!) Edit: (Well, I TRIED to upload an old picture. FAIL!!) (Message edited by steeleagle on September 08, 2011) | ||

Lemonchili_x1 |

Stuff like this? Yep, except you went to the competition! Actually we do use some Siemens gear for some field devices, but not on the energy side of things. My perception is that MOST companies who claim to be interested in saving "energy" are actually interested in saving "money". I don't really see anything wrong with that logic. Very few companies are in a position to spend money to reduce energy consumption, but if reducing energy use reduces costs it's a win-win, and they get to be seen as environmentally responsible; "good corporate citizens" seems to be the phrase. Reducing actual energy consumption (KWH and BTUs) without capital expenditures is more about behavior control and getting employees/occupants to accept modified consumption strategies. That's a huge part of it, and for companies willing to embrace change there are big savings in energy/$$$ to be had. Some of the projects we do are integrated with the lighting system motion sensors and we use that to change the setpoints or even turn the air-con off. Those sort of features are (finally!) becoming the norm. For me it's actually a pretty exciting time, I'm finally starting to see genuinely smart buildings, but it takes a fair bit of work to get people to see what's possible and to accept the changes in the way things work. | ||

Lemonchili_x1 |

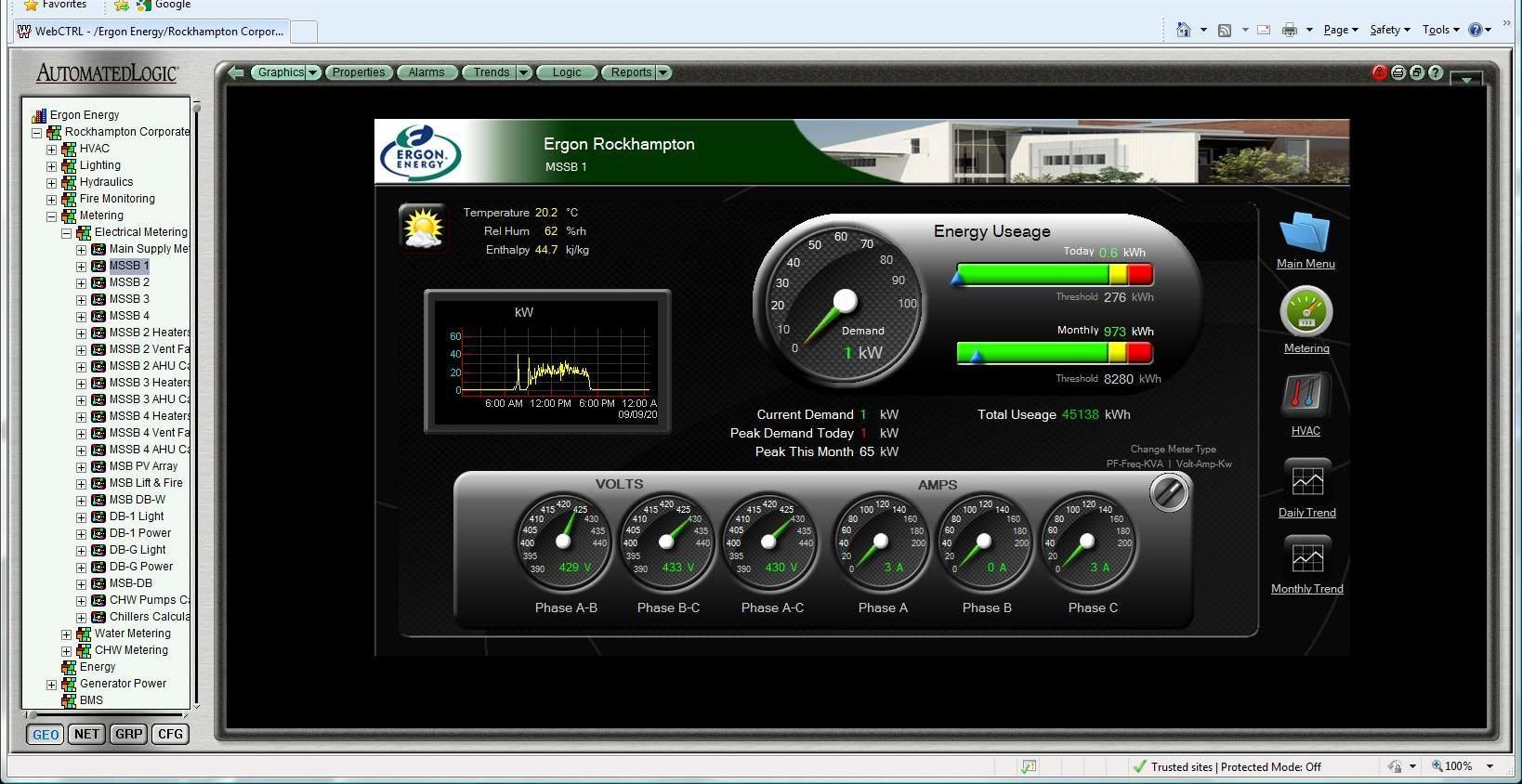

This is the kind of stuff we've been working on:  The main gauge also has a red pointer which shows the peak for today. The two bar graphs are pretty cool - For this building the yellow means we've gone above the target threshold kWh's, and if they go into the red they've gone beyond the NABERS design thresholds (NABERS is the Australian equivalent of LEED). Since this building was commissioned in March we've been below the target thresholds every month  You can see on the kWh graph that I've still got some tuning to do to stop the chiller firing up at 7.30am You can see on the kWh graph that I've still got some tuning to do to stop the chiller firing up at 7.30am  We have a page like this for every electrical meter, a simpler one for water meters, and we can do virtual meters which are calculated from other meters or from plant like chillers and VSDs. | ||

Steeleagle |

We're in the process of integrating light controls into our HVAC/Building Automation System. I'm not familiar with the technical details (yet) as I formally transition back to Facilities, but we get told by employees that with reduced light levels, the hallways are "too dark". "Too dark for WHAT?" Re; Energy/Cost reduction being win-win: Absolutely! It just kind of annoys me when companies imply that that they're driving the "green" bus when the reality is the only "green" that motivated them is cash. The PR spins make me cringe. I'm not a clinging tree-hugger, but I DO value our natural resources and capitalize on environmental opportunities to reduce/re-use/recycle and conserve energy. It's tough to sell a project simply because "it's the right thing to do", and I understand that the economics have to exist. We only recently started night-setback for our HVAC systems, something I was designing into controls in the 80's. To my amazement low-hanging fruit like this has never been utilized here, even though occupancy is basically one shift. We're seeing pretty impressive benefits. Some tweaking is still in process to ensure we get area temps where they need to be before occupants arrive, but barring our "technicians" modifying the operating parameters (usually done in the name of less work!) it's benefit is obvious. We need more metering here. If you can't measure it, you can't control it! But several opportunities to install metering associated with equipment installations have been scuttled because the immediate impact was seen only as added cost. Poor salesmanship! | ||

Fast1075 |

Around here, if anybody saw the R/H at 62%, there would be a building occupant with the sniffles and an army of IAQ hired guns and a flock of lawyers. all drooling over it.  Ready to pick the bones of anyone with a dollar in their pocket. Ready to pick the bones of anyone with a dollar in their pocket. One of our clients is a large banking corporation...they own an office building in town...lets say they ended up with it after the building bubble burst...have not been able to sell it, so they leased it out. We do all their HVAC/R, so they called us in regarding IAQ problems...the former owner had run the building into the ground..the zoning systems didn't work, in one case, the a/c unit for one floor was literally wired to run continuously, with a toggle switch to shut off if it got too cold. The controls were Mod 1 Tracer, and had been bypassed (completely obsolete)and the air handlers had variable inlet vanes that had been hacked out...the systems that had any controls at all were running on return air average. The tenants were hopping up and down about air quality and lack of control...they brought in their own IAQ people who wrote a very poor report. The bank got bids from us, Honeywell, Carrier BBS, Trane BBS and from York. They looked at all the bids, broke the lease, and sent the tenants packing. The building is unused and will remain so, unless they decide to do something with it. A similar building, in the same situation was recently torn down...it was too contaminated with aspergillus to save...watch the RH... | ||

Blake |

Blake not know acronyms "R/H" (for me that means "right hand") or "IAQ" (indoor air quality?), or "RH" without the slash. Also unsure of the "R" in "HVAC/R"; refrigeration? | ||

Steeleagle |

R/H and RH = Relative Humidity IAQ = Indoor Air Quality (Good guess!) "R" in HVAC: I'm guessing, too, but I'll go $5 on Refrigeration! | ||

Lemonchili_x1 |

Yep, the R is for refrigeration. I think the R is usually referring to un-ducted direct expansion (ie DX split) systems used for cool rooms etc to differentiate it from ducted air-con systems (which might be DX or chilled water). Around here, if anybody saw the R/H at 62%, there would be a building occupant with the sniffles and an army of IAQ hired guns and a flock of lawyers. all drooling over it.  Pffft, it's not even wet season yet!  Those numbers are actually the site ambient conditions, and we're having weird weather again this year, usually it would be a bit drier and cooler this time of year (it was around midnight when I took the screen capture). I had to look up aspergillus! Yes, the dreaded mold, but interestingly it's not a huge issue here in Queensland. For general office space we rarely see systems with humidity control. I've never really thought about it but I guess it's because in summer we use cooling so much of the time there's the natural dehumidification off the cooling coils, and winter its dry enough not to matter. Typically an office floor at 23° setpoint will be in the range 55 to 60% without humidity control in summer (when it's not raining). Too dry and static can become an issue in winter. Data/comms rooms are a different story and usually have humidity control. Sydney and Melbourne have more issues with mold and "sick building" syndrome, but I'm sure it could happen here. CO2 control is one of the flavours of the month here, and here to stay I think because you can reduce outside air use if you're clever about it. I've also installed Volatile Organic Compound (VOC) sensors in some sites, but there is no standard for the measuring of VOC yet. | ||

Blake |

>>> Those numbers are actually the site ambient conditions The sunny day icon kinda tips that.  | ||

Kenm123t |

We do quite a bit of IAQ work currently working on Job where the Equipment water source heat pumps didnt work. The Well Know Ft Lauderdale based company now owned by the Germans. Supplied water source heat pumps with R 410a that do not control humidity. We have removed them and replaced them with Daikin VRV systems and Desertaire 100% Outdoor air units. Look Up ourladyofflorida.org The Chapel is open 6am to 8 pm we can have as few as 6 for morning mass or 500 for a retreat. We are using a Mcquay watercooled pacakage unit with a Desert Aire 100% outdoor air unit for first stage cooling and it switches to 1st stage outdoor air once we need 3 stages of coolng or CO2 gets to 800ppm. Once fully loaded it and the secondstage CO2 sensor operates and adds in the balance of outdoor air but its untreated. if outdoor air is needed and we are not requiring full cooling such as around xmas temps are low humidity high we run the unit fully loaded and stage on hot water reheat for trimming temps. Or just run heating and pretreat which includes heating when its winter. On this project we are using a Johnson NCE to run it and the pump station and interface the Daikin I touch through IP. I just replaced the VFDS due to a lighting strike. and the new pumps controls will be installed fri and we will commission them mon -tues. I ll post some pics fri I ll finish the recomissioning the Surgery center on fri We have Andover controls on that site. | ||

Bigdaddy |

I don't know what most of the acronyms and stuff stands for. However, your SCADA front-end, AL product, is a familiar site. I learned to code writing for Slick 50's...good times (not so much). | ||

Kenm123t |

Oh I forgot to mention the Father Paul the principle Priest At Our Lady Of Florida Was the FBI Chaplin for Ny on 9/11 he spent weeks working with the surviviors |