| Author | Message | ||

Hex |

How do you get Dick-en Cider?  | ||

Hex |

Where can I buy Dick-en Cider?  | ||

Hex |

How much it cost for Dick-en Cider?  | ||

Hex |

Do you prefer Dickens Cider bottles to Gusher Well kegs?  | ||

Road_thing |

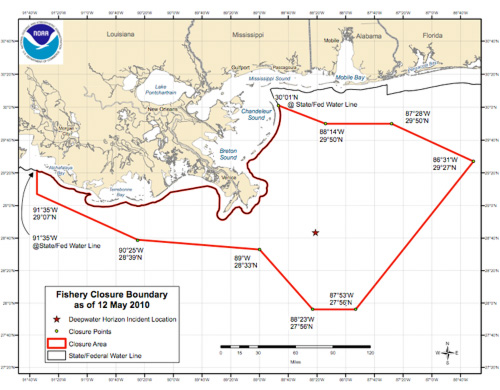

Right now, they've got a well in 5,000' of water flowing oil, apparently from the wellhead which is still intact and attached to the casing. If they can get latched on to the wellhead somehow, they have a chance to either (1) pipe the flow to the surface for collection or (2) re-enter the wellbore and pump mud and/or cement to stop the flow (this is the "top kill" being discussed in the news). If option (1) fails, they still have a chance at option (2) because the wellhead is still there and connected to the reservoir at +/- 18,000' below the sea bottom (+/-23,000' subsea depth). If they nuke it, either at or below the seafloor, the wellhead will either be destroyed or cut loose from the casing. There would be no chance for re-entry. Then, if the leak isn't sealed, you've got a jagged piece of pipe leaking oil at an unknown depth beneath the ocean floor and your options for killing the well are greatly reduced. In my experience, total abandonment of the wellbore doesn't happen unless and until the well is permanently secured. You've got to leave yourself an option in case your primary plan fails. I think the relief well(s) are the best choice, even though they take longer than anyone would like. While they're drilling the relief wells, BP can continue to try for containment (the cofferdam setup) or plugging (the top kill). They might even get lucky and have the well "bridge off" (plug itself by formation collapse at the reservoir-well bore interface). If/when everything else has failed, the nuclear option might be worth considering. Until all the currently proven techniques have been tried, I think the risk is too high. rt ...but what do I know, I just do this stuff for a living... | ||

Kenm123t |

Hex if your not going to eat the fish do not torment them | ||

Hex |

Thank you RT. If this thing goes worst case senerio, I hope they have that nuke in place. This it the first thread I have ever seen RESURECTED from the Backfire board. Guess some good discussion is happening after all. Ericfuckin' Thomas RYAN | ||

Reindog |

This is the JC of political threads? If so, cool. | ||

Pwnzor |

| ||

Blake |

"If this thing goes worst case senerio, I hope they have that nuke in place. " Your preferred solution could well create the absolute worst case scenario, resulting in centuries long nuclear poisoning of the sea bed and down-current tidal coastal waters, failure to contain the blowout but rather expanding it far beyond the well casing into a truly impossible to control crater-sized or fissure-like breach. You certainly are not qualified to judge one way or the other. Pretending that you are is laughable. It is a very dangerously arrogant and reckless and way of thinking. We are lucky to have the world's top experts in the field working the issue. Russia outright lied about Chernobyl. Yet some would prefer to blindly trust Russian reports on the success and environmental impact of closing land-based (not deep ocean) gas wells (not oil wells) using nuclear bombs?

You never answered Cowboy's question about the local environmental state of fishing piers versus oil company docks. Your own preferred manner of fishing is irrelevant. And Cowboy made no assumption concerning your preferred manner of sport fishing. He only stated that you were a sport fisherman and asked if you had witnessed the state of fishing piers on the coast. (Message edited by blake on May 11, 2010) | ||

Hex |

Agreed. | ||

Hootowl |

Actually.... Plastics in the US are mostly sourced from natural gas. Most plastics in Europe are made from oil derivatives. The crackers there are set up for naptha. You'd think that with the price of natural gas these days we'd be sending a lot of pellets over there, but plastic is so cheap, it isn't worth shipping. It's actually more cost effective long term to build another plant close to where the demand is. Our growth right now is in the middle east. It's a "feedstock advantaged" region. If we don't use the gas, they'll flare it off. It gets in the way of the oil production. | ||

Whatever |

The nuke stuff is very insidious. I have been in the environmental field for 8 years... seen some nasty stuff, but the nukes... how the hell do they get rid of it besides natural attenuation... is there any way to "treat" it... again, trading two problems for one... | ||

Blake |

I dare you to say "nuke-you-lar". | ||

Hootowl |

Ha! You said "nuke-le-ar", it's "nuke-you-lar" dumbarse, the "s" is silent! ...from a family guy episode I think | ||

B00stzx3 |

Giant Tampax. Or a million regular tampaxes duct taped together. Problem solved. | ||

Hootowl |

If you had a waterproof comfort applicator, that might just work. | ||

Road_thing |

Here's a refreshing opinion on the subject: T. Boone Pickens on placing the blame for the blowout rt | ||

Milt |

Where's the fun in that? | ||

Hex |

T. Bonne just came out with that? I said it May 3. Blame, doesn't really matter at this point, it's all about responsibility. | ||

Hootowl |

Just got this email from a friend at Cameron. The attachment will be presented to congress during the dog and pony show they're throwing. From: Harrell, Rosemary On Behalf Of Moore, Jack B Sent: Wednesday, May 12, 2010 9:01 AM Subject: Communication to all Cameron employees Importance: High Dear Fellow Cameron Employees, The tragic oil rig accident of nearly two weeks ago has affected all of us -- I know from your many calls that your thoughts and prayers along with mine are with everyone affected, especially the families who lost loved ones. I thank all of you for your work during this time. A great number of you are making an extraordinary personal commitment to work with everyone to get this well shut in. On Wednesday, May 12, I will speak before the U.S. Congressional panel that is investigating this tragic accident. The panel’s goal, like ours, is to seek answers for what caused this tragedy. I want you to know that I am proud to represent you, our Company, and the great work that we do. Attached is a copy of my written statement submitted to the Committee in advance of the hearing. Please feel free to share these remarks with friends and family. We are a leader in our Industry and are widely respected for what we do for our customers. That reputation has come from the professionalism and dedication of all of you. I urge you to continue your focus on providing the best products and services to our customers. Thank you again for all that you do for Cameron each day. Regards, Jack B. Moore President & CEO Cameron 1333 West Loop South, Suite 1700 Houston, TX 77027 office 713.513.3300 fax 713.513.3455 ***This is the text of the PDF*** United States House of Representatives Committee on Energy and Commerce Subcommittee on Oversight and Investigations Written statement of Jack B. Moore, President and CEO of Cameron International Corporation May 12, 2010 I am Jack Moore, President and CEO of Cameron International Corporation. I have been with Cameron for 11 years and have over 30 years of experience in the oilfield service industry. I appreciate the opportunity to be here today for this very important hearing on what is truly a tragic event. Since the day of the incident, we have been lending our assistance. We will continue to work with everyone involved to understand what and how this happened. Cameron is based in Houston Texas and is a leading provider of equipment and services to the energy industry worldwide, with 11 different operating divisions and approximately 18,000 employees in more than 300 locations. We have worked with our customers for over 120 years to design, manufacture and service products that help them safely find, develop, produce and transport oil and gas. The Cameron product used by the Deepwater Horizon is called a “blow out preventer” or “BOP,” a product that Cameron actually invented in the 1920’s, that allows our customers to control the pressure in a well while being drilled. There are over 2,500 Cameron BOP’s operating around the world today, both onshore and offshore. We have over 400 BOP stacks operating offshore, of which 130 are operating in deep water. Each individual BOP stack is made up of components specified by our customers, is configured to their specific operating specifications, and is tested and manufactured in accordance with industry standards and applicable regulations. Our BOP’s have a very long history of reliable performance, including performance in some of the harshest operating conditions in the world. In support of our commitment to our products’ on-going performance, we maintain a system of safety alerts and product advisories that keep our customers abreast of the latest information about our products. As soon as Cameron was notified of this incident, we mobilized a team of our best drilling systems specialists to work with BP and Transocean to assist in shutting this well in. We also mobilized teams from our sub-sea, surface and valves divisions to assist BP and its partners in the alternative methods they are deploying to contain the flow from the well. We have been working around the clock to assist in this effort, and we will continue to provide all of the resources at our disposal until the well is shut in. It is far too early to draw conclusions about how the incident occurred. The present challenges involved in determining causes are many, in particular, from our standpoint, the inability to examine the Deepwater Horizon’s BOP. Everyone of us is mindful of the personal, environmental and commercial concerns associated with this incident. We understand the need to discover the facts relating to what went wrong and to do all that is possible to prevent the occurrence of such an incident in the future. | ||

Aeholton |

Simple, elegant solution: | ||

Hex |

Yup, human and pet hair seem to work as well, but this is not a solution to stoppering the well. Looks way 'greener' than dispersant. IMO | ||

Blake |

I wonder how the hay/straw performs after floating in salt-water for a while before coming into contact with crude oil. Might not be so effective after it is water-logged versus bone-dry. Looks like it would be effective if blown directly on top of the oil. Cows might have to go hungry. Price of beef would likely increase. Probably well worth the sacrifice in my view. | ||

Aeholton |

Looks way 'greener' than dispersant. IMO This is, also, "greener" than standard dispersant: http://finance.yahoo.com/news/Corent-Company-Everg reen-prnews-1787435023.html?x=0&.v=1 | ||

Aeholton |

Quote from above link: G-MARINE Fuel Spill Clean-UP! is a unique blend of plant derived, water based and ultimate biodegradable ingredients specifically formulated to quickly emulsify and encapsulate fuel and oil spills. These plant derived ingredients are processed to form a colloidal micelle whose small particle size (1-4 nanometers) enables it to penetrate and breakdown long chain hydrocarbons bonds in oils and grease and holds them in a colloidal suspension when mixed with water. Once oil has been suspended in a nano-colloidal suspension, there is no reverse emulsion; the oil becomes water soluble allowing it to be consumed by resident bacteria in the water. This dispersant formula is protected by trade secrets pursuant to Occupational Safety and Health Agency (OSHA) Standard CFR-1910 1200. The ingredient list has been reviewed by the US EPA and contains no ingredients considered hazardous by OSHA. | ||

Hex |

| ||

Hex |

| ||

Hex |

Criminal charges likely from Gulf oil spill, legal experts say http://www.mcclatchydc.com/2010/05/12/94061/federa l-laws-point-to-criminal.html | ||

Road_thing |

Here's an interesting website a buddy of mine sent me this morning: http://jccac.com/Horizon/ The site owner has a sportfishing guide business on the Mississippi Gulf Coast, so he has a vested interest in downplaying the negative effects of the spill (guides don't make any money if nobody comes to fish), but he has apparently been on the scene in person and posted quite a few pictures of what's happening out there. rt |