| Author | Message | ||

Malott442 |

And it sure wasn't the paper gaskets. HYDRAULIC LIFTERS!!!!!!! I just did my valve adjustment on my 955i daytona, and I tell you what, if I have to strip my bike that far down again I might let it continue down and part it out haha! I dropped my 8mm socket down the cam chain hole, had to fish it out the hard way (take starter cover and starter off). All in all, about 8 hours labor. BUT, my tolerances are spot on. She's good to go. But yeah, I will say openly that if BRP decides to build motorcycles, they might consider in their bottom and touring models a hydraulic lifter, or at least package the setup to take less than 2 hours, my time (perfectionist, probably have no business looking at "specs", they drive me insane). If something has a spec of .0078 to .0119, then I am going to shoot for .00985 somehow. Even though I know the tolerances are likely to tighten up. But yeah, sign me up for hydraulic lifters, they rock!!! | ||

Froggy |

You can keep them. If the engine is designed right, valve adjustments are easy. See the 1125R for example. Hell it is easier to do the maintenance on the 1125 than the XB, plus you don't have to service it as much.  | ||

Malott442 |

The motor in the Triumph is designed fairly well for quick adjustments, its just getting to em between the frame rails that is taxing.... I haven't got to play with the 1125 yet, though I thought the xb wasn't packaged too bad besides the damn spark plug location....... | ||

Ourdee |

XB plugs; (trick) it's all in the tools. 11 1/4-20 bolts and you are looking at them. spark plug wire tool. (don't think about putting your fingers in there) open end wrench for the front. u-joint socket for the rear to loosen it. 1/4"x12" piece of fuel hose for getting it out and back in. | ||

Gentleman_jon |

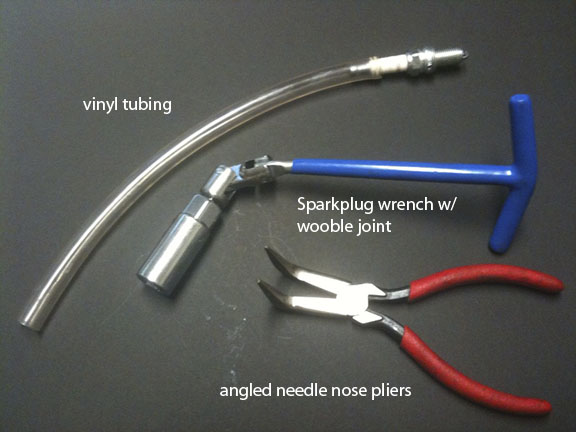

spark plug tool kit illustrated:  | ||

Ulynut |

You forgot the piece of string for getting the velocity stack back on.  | ||

Ducxl |

I like my hydraulically lifted Buells' too. Desmodromic valve adjustments and belts replacement is arduous but rewarding at full song  | ||

Diablo1 |

You can keep them. If the engine is designed right, valve adjustments are easy. See the 1125R for example. Hell it is easier to do the maintenance on the 1125 than the XB, plus you don't have to service it as much The motor design is fine, but the frame design requires you to rotate the motor before removing the valve cover. What's the flat rate on that? } | ||

Brumbear |

I use an old plug wire to thread em in and longer neck needle nose | ||

4cammer |

"You forgot the piece of string for getting the velocity stack back on." Ulynut, I owe you one. Great idea. | ||

Greg_e |

Hydraulic lifts cost a huge amount of space in an overhead cam engine. Good for a car where you have the room, not so good in a cycle. That's part of the reason so many go with shims. Cycles with adjust screws are far more flexible but take up slightly more room than shims. | ||

Teeps |

4cammer Posted on Sunday, December 20, 2009 - 10:28 am: "You forgot the piece of string for getting the velocity stack back on." Ulynut, I owe you one. Great idea. As, do I... He's been around auto glass installers, or been one, I'll bet. I've seen the procedure enough times that I should have thought of that too... Instead I've been using hook to set the velocity stack grommet. | ||

Etennuly |

I use a hook tool too, with the light oily film that is always on it, it goes back in seconds. Don't forget your anti-sieze for your install kit! | ||

Cowboy |

It has.--enouh speed o get you more tks. than you can pay for.---Enough torque to handel any type of city trafic---and it is as tough as Justin boot leather. | ||

Firemanjim |

Mathew, just had the head off my Triumph Sprint,not too bad. Did the valve adjustment on the bench while it was off. Not any harder than any other bike I have done. Though,I must admit,I always liked the ease of working on the tubers! | ||

Malott442 |

would'nt doing the adjustment on bench possibly skew the readouts? Without the head being torqued to the block, it might. Maybe I'm reading a little too much into plane distortion factoring into some billionth of an inch in cam to follower relation. leave it up to an engineer..... It almost would be easier to get the head off and adjust on a bench haha! After having to swap shims just a 2nd time the task becomes a matter of joint pain in the fingers and lower back cramps from being bent over, listening to the same Styx song for the 3rd time because the autoplay at the radio station obviously malfunctioned.... That was when my 8mm went down the cam chain hole. oops! Jim, do you have a current model sprint or an older one? Ive always wanted an older model, or maybe a steamer. Orrr.... the list from that manufacturer goes on and on.... kinda like my Buell fetish! | ||

Ourdee |

I use an aluminum tent spike for the velocity stack. Put it in the groove and keep rotating it. | ||

Firemanjim |

I have a 99.and now an 02. Install went well and it came back to life last night. Sounded good.Now to clean it up and put it up for sale. I have always used my fingers to do velocity stacks, you guys must have some real stubborn ones! |