| Author | Message | ||

Reepicheep |

I had been running Mobil 1 in my tranny for several thousand miles before the teardown, and saw no evidence of damage to any brass. In fact, I can't even remember any brass in there. I think the shifter forks were bronze, which is part brass, but not sure if it is the same effect. Blue M2... congrats on the extended warranty! You would have been up to around $450 in parts easy, and maybe that much more in labor. | ||

Mikej |

Is the dealership allowing the warranty coverage with the aftermarket stuff you have? My last interchange with the warranty person tells me I'd have a battle on my hands to get coverage. I've always ran the SportTrans lube in there. I'll try to open mine up and at least do a limited peak. Is there any other indicator to check for without any disassembly? | ||

Bluzm2 |

Really the only aftermarket motor stuff is the SuperTrapp and the CF ham can. All Buell parts. This is the second time they went through the tranny. Last fall the clutch main bearing went bad. They wound up replacing a bunch of parts. I need to check the service sheet as I think the 5th gear assembly was on the list of replacement parts. As far as other checks, I think pulling the dust seal is about all you can do without "going in". Brad | ||

Tripp |

my bike seems to need to catch up with itself in first gear, when you let the clutch out in first only it doesn't catch the gear till a split second later and kinda slaps into gear, all the other gears are fine, the bike runs fine otherwise i just have to listen for it to kick in before i flog it kinda let it do a half turn before i hit the gas or it pop real loud and that can't be good, so i half clutch it till i hear and feel it kick in, anyone know anything about this or what it might be? thanks, tripp | ||

Bomber |

sounds like the infamous first gear rounded off dog issues . . . . . .backcutting the dogs on first gear cures this, but it does (of course, require pulling the transmission . . . good winter project | ||

Bluzm2 |

Tripp, How does your clutch feel? I had the same problem last year. The clutch bearing was shot along with a number of other internal gears. They should have looked at the 5th gear assembly a bit closer. I pick it up today after they had to redo the whole thing including 5th. Thansk God for extended warranties. Mine expired on the 29th! | ||

Tripp |

the clutch seems fine, i get a strange feeling it's a weird buell thing like an infamous round dog thing, lol, i let the clutch out till i hear the click and let her go and she's fine after that, but it's really annoying when it does it down shifting into first which i've only noticed recently. definitely something i'd do after the good weathers gone if it's a tranny pulling project! | ||

Road_thing |

If your dog is too round, cut down on his kibble... r-t | ||

Bomber |

we need to get thing out in the wind, i'm thinkin | ||

Road_thing |

Sunday, Bomber, Sunday! Manana, I have chores to do at el ranchito chingadero. Subject to successful completion of same, my retention of all my vital phalanges and the whims of ol' man weather, I and several other Houston area Buellers will terrorize portions of Austin, Washington and Fayette counties on Sunday! I'll try to remember my camera this time. r-t Speaking of wind, "May the wind at your back be your own!" or something like that.... | ||

Giraffeman |

This is vey embarassing but where the hell do you put the tranny oil in? I found the outlet under near the exhaust but can't figure where this dipstick is supposed to be??? Stupid rider neads help, again..... | ||

Mikej |

There is no dipstick per se on your X1. To check the tranny/primary fluid level you remove the four screws holding the clutch inspection cover on. Look in your service manual for the proper level. To refill it, level the bike and pour the lube into the opening allowing it to flow into the tranny. It will not take a full bottle. Note: do not loose the little lightweight spring that sometimes sticks to the inside surface of the clutch inspection cover. Note2: The clutch inspection cover is held on with four screws, the other cover with the two screws is for inspecting your primary chain slack. Your service manual will detail this as well. Having no idea where you're located there may be a local Buell dealership that stocks the service manual for your bike. If not then one of the sponsors on the site here can surely get one to you. Note3: fill out your profile a little bit more, it helps people to answer your questions. We don't need to know your exact street address or the hours you are home, but it is nice to know at least what country or continent you are located in or on.  Any more questions just ask away. The search function on the site here is also very beneficial, though it can be somewhat overwhelming when it returns 5000 hits to an inquiry, or none.  | ||

Giraffeman |

Cheers for the reply. Ok then I am italian born in Martinique, lived in trinidad, curacao, st lucia, brasil, ital, back to brasil, now in england, own a pub two bars and a shop and ingaged with a drug dealer (pharmacist). And I love the buell even with its 'problems'. I prefere fun than speed. P.S. I hate dealerships, A bunch of know nothing charge a fortune, parts and labour cost at least twice as much here and we dont ern twice as much (only if you own a harley dealership). Hopefully I found a honest drag racing chap who will help me out. Cheers Alain ( Derby England) | ||

Mikej |

Well, didn't need the whole life history, but interesting none the less.  Not sure how close Derby is to where Rocket/SeanPepper is, but he probably can lend a hand or direct you to local decent dealerships. And since you're a proprietor he may even be persuaded to donate a service manual in exchange for quenching his thirst a bit. Be prepared for tall tales if he gets to talking though. But seriously, he'd be the guy I'd ask if I were looking for dealership leads over there. There is also a UK based web site of Buell owners that hopefully someone will still have the link to since I had to purge my bookmarks recently. | ||

Giraffeman |

Cheers for the advice. I prefere to stick to US or international sites as they tend to be better in every way. | ||

Bomber |

Long Necked One do not remove the clutch cover (four fasteners,as Mike said) with the bike on the side stand, or you will learn to clean up trans fluid in a hurry, as it will flow out through the clutch opening if it is leaning over on the stand . .. the bike has to be vertical to check the level in any event also, those bolts are torx heads, unless some kind soul has already replced them with allen head fasteners (1/4 - 20, if memory serves) | ||

Al_lighton |

One other tidbit of info you may find helpful... Loosen each screw, then retighten it mostly (but don't torque it down. THEN take all four out. The derby cover has a quad seal on the back side that will •••• the cover most heinously after three of the four screws are out, and between the prevailing torque of the tightened 4th screw, PLUS the cocked cover, you are guaranteed to not be able to loosen the 4th screw without totally stripping the head, especially if it is still the evil torx head fastener. Many a Bueller/sporty wrencher has had to drill the head off that 4th bolt before learning the loosening-all-4 trick. Al | ||

Reepicheep |

Speak the truth Al! That was my very first Buell "bonding moment" with my new to me Cyclone. Speak the truth Al! That was my very first Buell "bonding moment" with my new to me Cyclone. | ||

Bluelightning |

Been there done that. Lesson learned....  | ||

Jpc |

Many thanks to all those who posted the details of the outboard maingear needle bearing replacement surgery, it has helped me immensely. I'm currently waiting for my rebuilt transmission to come back from the shop (I probably could have afforded the hydraulic press needed for the rebuild, but not the addition to my garage that it would have been required). The shop guys recommended assembly lube for the needle bearings, I seem to recall lithium grease being mentioned as well. Is there any fresh information as to what is best for use in contact with HD Sport-Trans fluid? | ||

Reepicheep |

Cool JPC, let us know how it goes! Lots of pretty scary steps on that job... | ||

Jpc |

The sordid tale so far... '00 Sportster 883/1200 with 52K troublefree miles begins to make ominous noises from front belt sprocket area. Front belt sprocket has both radial and axial play. Dealer says special tool for maingear removal is "not available", then "we can order it through Drag Specialties, but it'll take at least a month", so I measured the shaft positions and dummied up a tool from some 1/4" X 2" flat bar and 1/2-13 all thread I had laying around. The flat bar was insufficient, so I spent the next Saturday morning making two hand hacksaw cuts through 3/8 x 2 1/2 flat bar and drilling the holes. Drank beer on Sunday as my arms were too tired to wrench... The maingear ball bearing was lunched, with a fair amount of ground metal between it and it's outer seal. The outboard needle bearing was intact but filled with blackened oil. I was intending to replace the maingear because the outboard end showed discoloration, but when I looked at the new part it had the same pattern. I suspect that the sprocket nut threads are annealled to reduce brittleness of the otherwise hardened and ground gear and splines. So I had new needle bearings pressed into the existing maingear, lubed them with Sport-Trans fluid per the FM (mistake #1), and reassembled it into the new ball bearing in the case. The tranny cartridge itself seemed to be OK, with only some discoloration on the outboard end of the mainshaft corresponding to the fried needle bearing. The surface finish was unblemished, so I figgered it would be OK (mistake #2). Reassembly went smoothly, without any indicators of problems. The test ride was conducted with caution, up and down the alley, careful check; around the block, careful check, etc. Shifting was good through all five gears, no unusual noises or smells from the breather tube, all systems go. Next day, a quick warmup ride to the hardware store for a rear axle cotter pin, then back to the Hog Barn to suit up for a nice long ride. Less than a mile from home, a new noise begins. I decide to nurse the bike home (mistake #3). 30 feet from the garage at about 5mph, the rear wheel locks, clutch does not release it. I dropped the belt and pushed the bike the mercifully short distance into the Hog Barn. Sprocket loose (nut threads on maingear stretched), maingear seized on mainshaft, it came out of the case as a unit. Disassembly at the dealer reveals one lunched shifter fork but apparently no other damage so far. The shop will install a new mainshaft, shifter fork, bearings and clips. I have installed new ball bearing and mainshaft, and will pack the needle bearings with assembly lube (unless somebody can suggest something better) on Tuesday or Wednesday when I get the tranny back. I have precise dimensions of the hole pattern for the maingear pulling tool if anybody's interested. But you'll have to cut the steel yourself - my arms still hurt. | ||

Reepicheep |

I made a special trip to Harbor Freight and got a 4" cutoff tool, but otherwise our approaches sound remarkably similar, all the way down to the collapse of the "rev 1" tool and success with the "rev 2" tool. I made a special trip to Harbor Freight and got a 4" cutoff tool, but otherwise our approaches sound remarkably similar, all the way down to the collapse of the "rev 1" tool and success with the "rev 2" tool. My main outer bearing was fine, but that does not matter, as you have to destroy it to press it out. My inner bearings were in a big rusty pile of ground up metal. My shaft was toast, there are pictures in the knowledge vault. From what you describe, I don't see any "serious" mistake. My mainshaft was a mess, and ran that way fine (though with increasingly sloppy shifting) for at least 5000 miles, all the time those chewed up needle bearings being reduced to a plain bearing (though admittedly lubed with mobil 1 gear oil). The fork replacement is not a terrible job, but lots of little pieces to loose or put in backwards, one nasty "pound this part free" moment, and a lot of head scratching to get it back together with the million or so shims and gears, all of which look alike but each of which is subtly different. I wonder what your second failure was? I can't believe it was assembling with the sport trans as assembly lube, it's not a perfect approach, but surely not disasterous. I used mobil 1 gear oil and soaked every part before I put mine back together, which should have had about the same net effect as what you did. Could a bearing have been put in cocked? Bent up and siezed during install? You have a great attitude about the whole thing... Keep walking towards the light. | ||

Jpc |

I did a biopsy of the original failure of the outer ball bearing while disassembling it for use as part of the tooling for reassembly. The inner race was trashed for 120 degrees of its circumference, the whole groove gouged out and as ugly as a tax audit. Outer race had a single 1/4" diameter divot. I'm very surprised the whole thing didn't explode on the 80 mile ride home from where the noise first started. I am using the parts of the trashed bearing to assure that I won't put ANY thrust on the wrong race during installation of the new mainshaft. I ground down the OD of the outer race for a slip fit into the case bore to pull the new bearing in. I'll use a 1 3/4 hex X 3/4 square drive socket to pull the new mainshaft into the bearing. The needle bearings are about as long as they are big around, so the only way they could be cocked would be if the old maingear had been warped out of cylindricity - possible but probably not worth the setup to check. The guy at the shop (who asked if the tranny came out of a Sportster or a Buell) noted that he had a stock tranny just like mine in his "9 second drag bike" and that he had never seen a failure like this in his many years of professional wrenching. I'd really like to feel that ALL of the underlying causes of the failure have been corrected by the time I get this project finished. | ||

Reepicheep |

How did the inner race get grooved out without damage to the shaft? Maybe there was just some critical chunk of "junk" left in the tranny after the previous rebuild... and you got really unlucky... Dunno... | ||

Road_thing |

"cylindricity" There's a new word for me! And all these years I thought it was "cylindarity!" Hang in there, JP. rt | ||

Jpc |

Clarification: The inner race of the ball bearing was the initial failure - the tranny hadn't been opened for 52,000 miles. The second ball bearing still appears to be good, although I'm not going to chance it and will replace it as part of the much more careful second reassembly. "Cylindricity" is the ANSI/ASME Y14.5M Geometric Dimensioning and Tolerancing approved term, I couldn'uv thunk up a mouthfull like that myself. I picked up the tranny today after work, and will post pictures of the reassembly if anybody's interested. | ||

Mikej |

"and will post pictures of the reassembly if anybody's interested" Yes please, and thankyou. Post some pics of the empty cavity as well prior to reinstallation, helps for folks to know what it looks like in there. | ||

Bluzm2 |

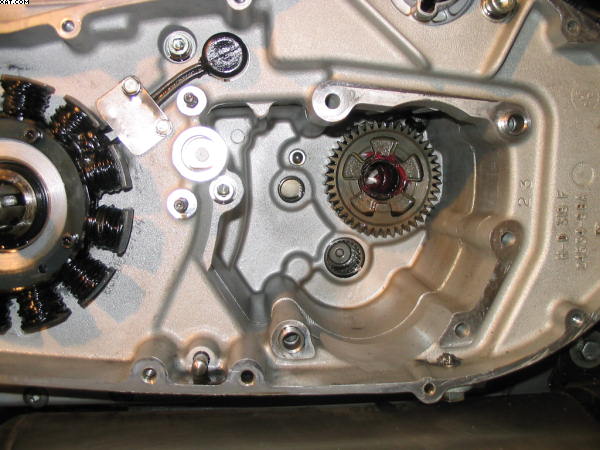

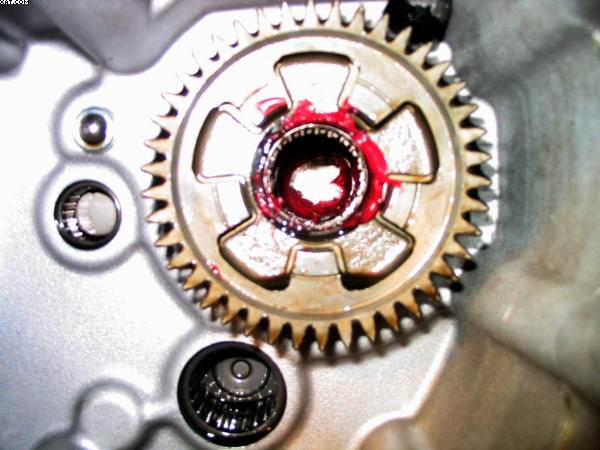

Mike You mean like this? These are from my 2000 M2 Cyclone Empty Primary Gear Case  Close up of 5th gear in case. I packed some synth gear grease in the needle bearing space as a bit of added protection. I figured it chouldn't hurt..  A few folks have had problems with the stator wires shorting out or getting cut through by the hold down clip. I checked mine and noticed a small bit of an indentation on the wires. I bent the clip slightly as shown in this picture to lessen the possibility of a short inducing cut. Stator wire hold down clip  Sorry for the somewhat blurry pic's, I'm still trying to figure out the close up function on my camara. I've got some tranny pictures also if anyone want to see them. However some are a bit fuzzy due to the above excuse...... Brad | ||

Mikej |

Exactly like that, thanks. Got any of the right side of the case? I'm planning on opening up one of mine this winter and do a little exploratory maintenance and possible tweaks or adjustments. |