| Author | Message | ||

Reepicheep |

I figured I might as well start a new clean thread for the topic... Symptom: 2007 XB12X with about 24k miles suddenly developed sustained and repeated stutters at around 3000 RPM. During stutters, tach indicated radically increasing and decreasing RPM's, while speedo remained stable. Hypothesis: Failing cam position sensor (leading the ECM to not know when to fire the coil, and the tach to read erratically). Test 1: I hooked up an inexpensive digital storage scope (about $100) to the cam position sensor lead where it connects to the ECM, and started the bike, and examined the waveform. Conclusion... um, I have holes in my waveform. Anyone else ever put a scope on a good CPS? What did the waveform look like? Stand by for pictures of mine... | ||

Reepicheep |

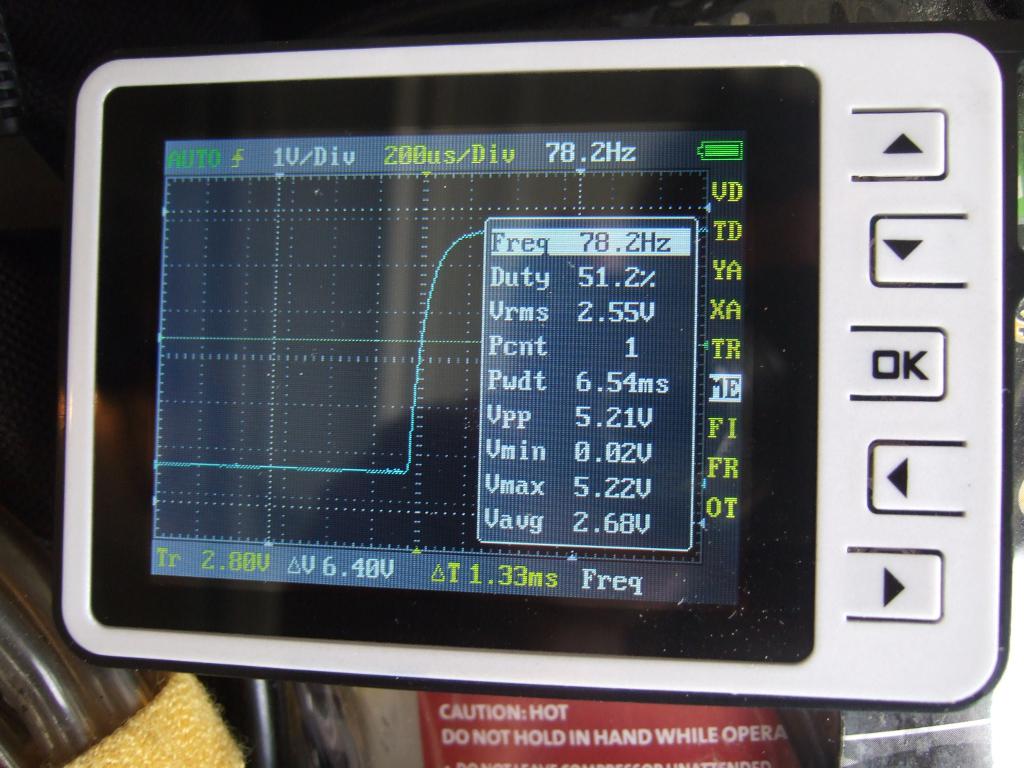

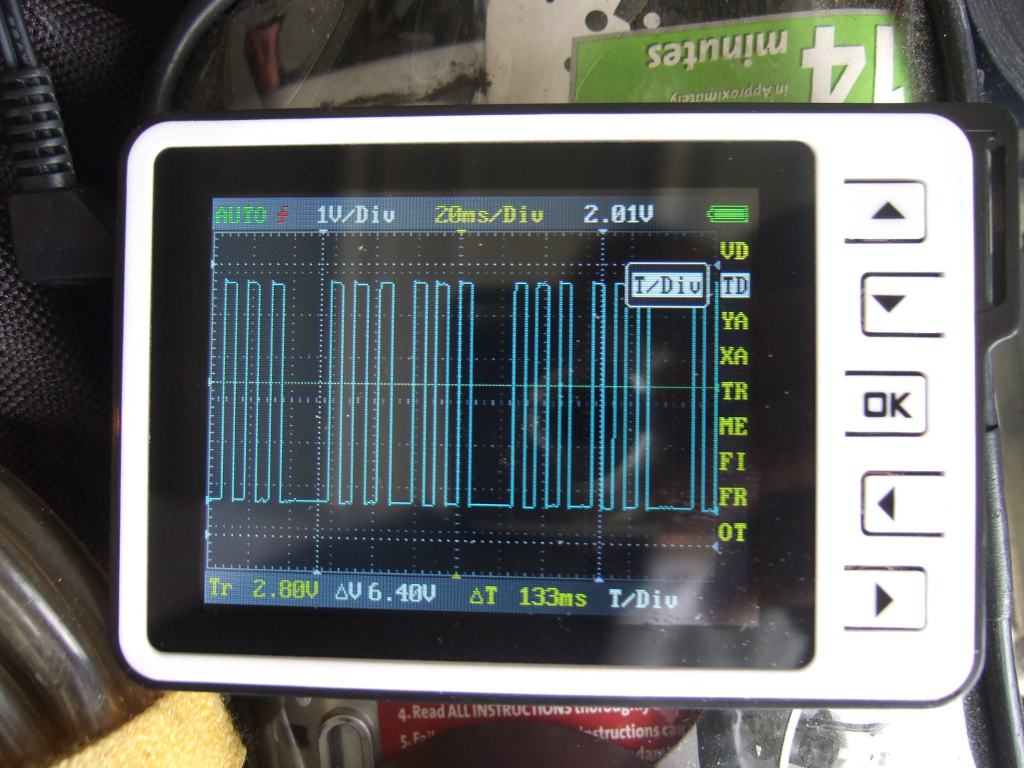

Frequency and voltage at idle....  | ||

Reepicheep |

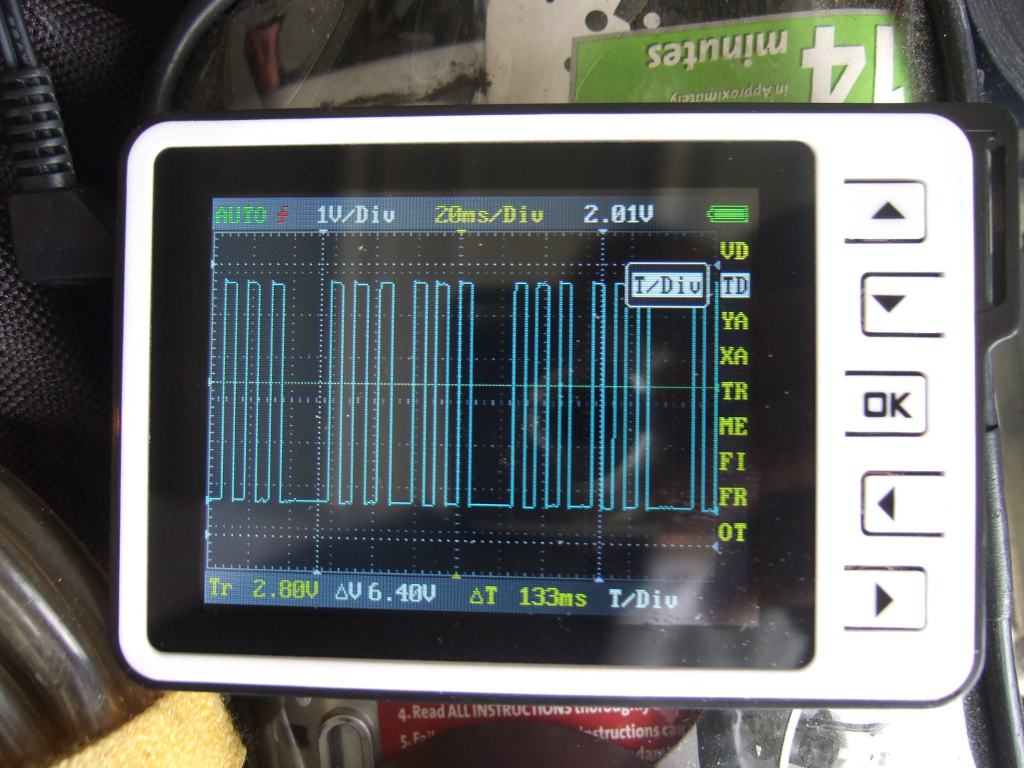

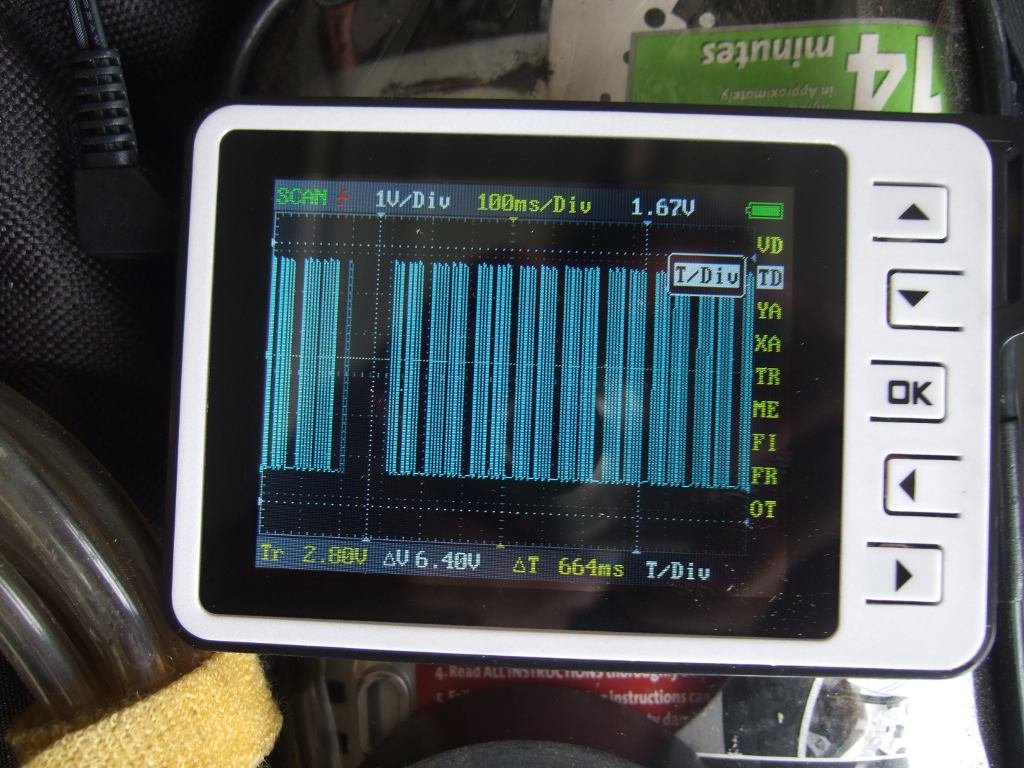

Lower timebase (more detailed view of the waveform)  Higher timebase (more waveforms packed on one screen) (Ignore the big blank gap, that is the refresh window that scrolls around as new data comes in and the image wraps around the screen)  | ||

Reepicheep |

So to me, that looks like a crappy signal. I expected it to be once per rotation and regular as clockwork. I will say that while this was sampling, the bike was running fine. I did not sample during a "stutter" yet. So observation 1: This little $100 storage scope ***freaking*** ***rocks*** for vehicle diagnostic work. Shows wave form, calculates frequency, even calcualtes RMS. How cool is that? Now I have to find out what the wave form is *supposed* to look like. | ||

Reepicheep |

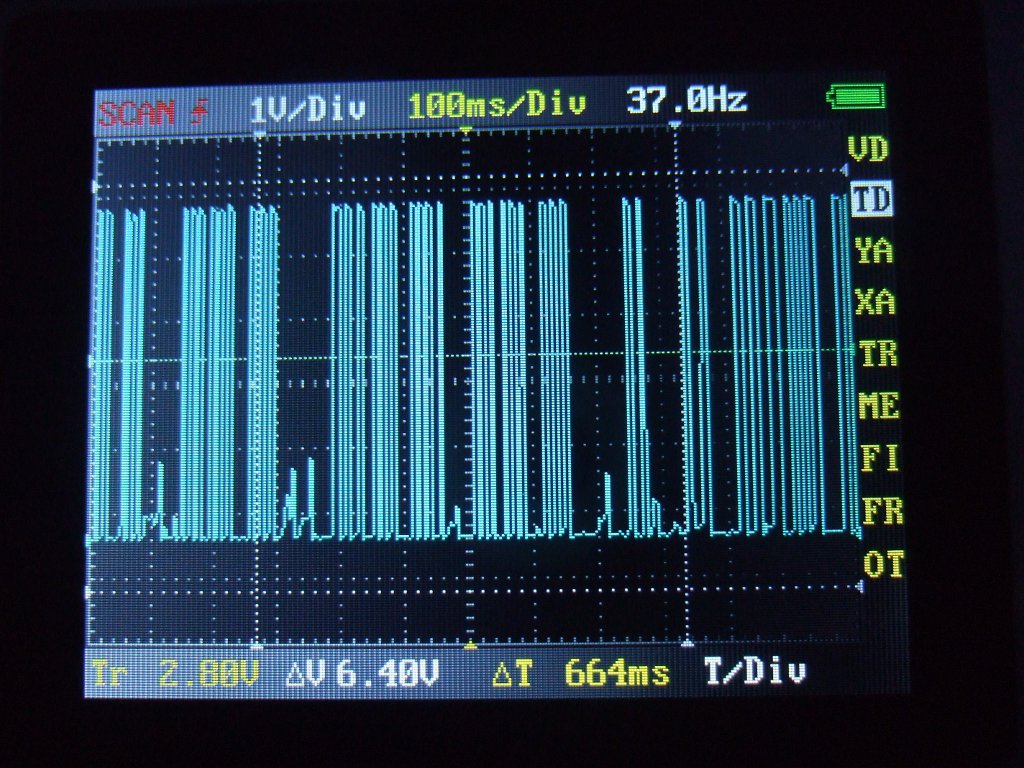

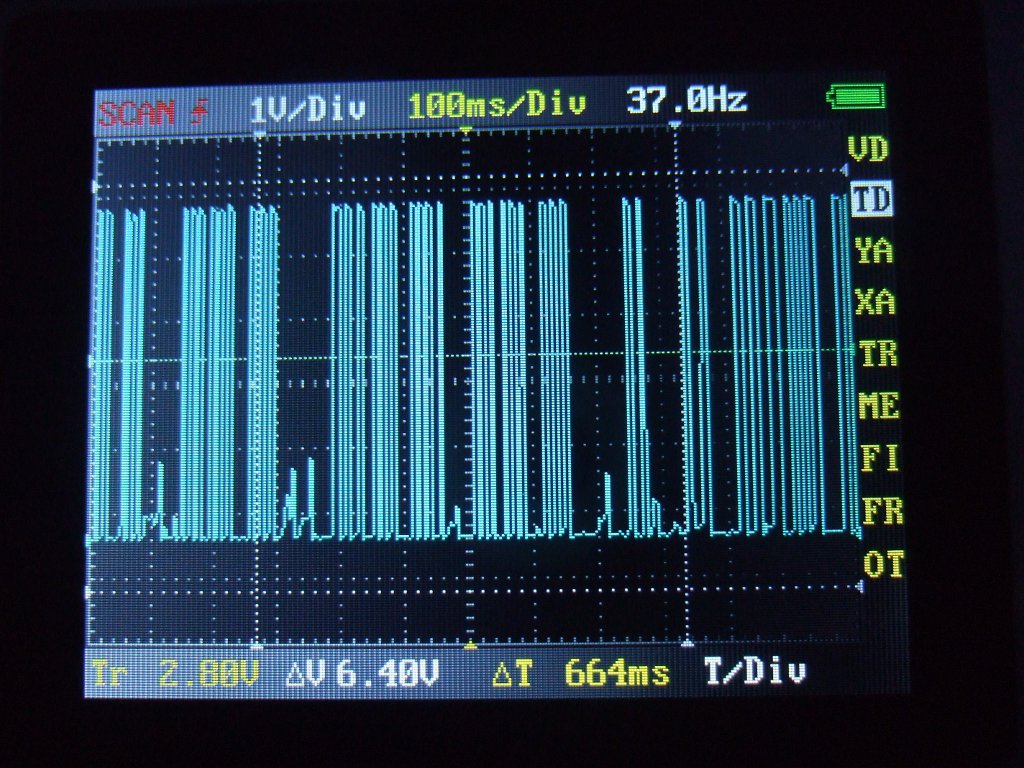

OK, thats really cool. Let it heat soak (idle until fan came on, turn off for 15 minutes) then took for a ride. Not 1 mile into it, it was worse than ever... barely able to stay moving. Limp back to garage, whip on scope before it can get better, and there it is...  Looks like I am on the hunt for a cps. | ||

Reepicheep |

You can see the coughing and sputtering... | ||

Reepicheep |

So lets do some math with the top plot (which presumably is a happy CPS)...  20 ms / division. Approximately 4.5 divisions. 4.1 div * .020 s/div = .082 seconds for a cycle. (1 rev / .082 sec) * (60 sec / 1 rev) = 731 RPM. Idle adjusted to around 1000 RPM, so that's plausible. So the cam position sensor (which I would argue is actually a crank position sensor, but Harley being Harley you have to take their labels with a grain of salt) must be sending 3 pulses for each "spark". One 3 pulse series for the first cylinder, one 3 pulse series for the second cylnder, then a pause (as this is a single pin crank on a 45 degree twin). Seems reasonable... so this chart shows a happy Buell XB cam position sensor. Then this chart hows another data point (with the mangled CPS output):  100 ms / division. Approximately 1 divisions. 1 div * .100 s/div = .110 seconds for a cycle. (1 rev / .110 sec) * (60 sec / 1 rev) = 600 RPM. So both seem a bit low, but the motor was running poorly. Plausible, but not entirely convinced. Maybe when I pull the CPS off I will see what metal the hall effect sensor is triggering off of, and see if I can see the three pieces of ferrous metal that are raised. Regardless of understanding the original wave form, the "error state" wave form makes it pretty clear the ECM is getting garbage data from the CPS when the bike is running badly. A uly sounds pretty cool when it backfires though...  | ||

Prior |

What model scope is that Reep? Been thinking about adding one of those to the toolbox (which is already too full)... | ||

Reepicheep |

DSO Nano, about $100 to $129. There is also a DSO Quad ($200). Both all over the place on ebay and amazon. The nano is working great for the kind of stuff I play with, automotive and home applications. It has plenty of bandwidth for that. It's limitations are input voltage (like 50 volts or something, or make your own voltage divider). And the packaging isnt really mature... so unlike my Fluke 77 that I am sure I could drive over and still use, I have to handle this with care. But for the price and for the portability (it is TINY) it is great. I had it with me in Franklin. | ||

Reepicheep |

Looks like they have some older ones for $79 also, and they have nicer probes. Don't know what the differences are. Also, the stock firmware that comes with it is decent, but the "BenF" replacement firmware is nicer (IMHO). Note: I hate Deutsch connectors. | ||

Reepicheep |

Cool! Pulled the cam cover. Sure enough, there are 6 slots in the cover, so there would be 6 pulses with the gap in the middle for every crank rotation. So if you 2x my math from above, it was 731x2 rpm (1462) and 600x2 (1200) RPM. Just about what you would expect cold and warm idle respectively to be. New CPM on order. Dang, these things are spendy. Also, Harley puts the Deutsch connectors together with the lock in the wrong position. For what that's worth. | ||

Reepicheep |

Anyone know why vehicle makers use a hall effect switch for this type of application? Why not an optical interrupter setup? Seems more durable and more precise. I'm half tempted to build one with $10 worth of pieces while I wait for the $130 Harley part. >  (If you are going to gouge on cost, at least deliver great service...) | ||

Reepicheep |

Sigh. The more I think about this, the less crazy it sounds. The only major downsides I can think of at this point are: 1) Resistance to "other issues". A hall effect sensor could run in a full oil bath and not be bothered at all. An optical system would have to stay clean. 2) Light interference. A hall effect sensor could run fine exposed to light, an optical system might or might not (depends on what frequency of light it is tuned for, and what the intensity is. #2 might be the biger issue. I also don't know what smarts are built into the current CPS... does it auto shut off if it is in the "on" position but not turning so it doesn't burn up your coil? Any auto spark advance baked into it? Good timing for research also, the KZ-400 I am restoring has mechanical points, which make me nervous (purely speculatively, I've never had to live with a vehicle with points, so I don't know how bad it really is). There are a variety of clever hacks to replace it... the later OEM kawasaki parts, aftermarket optical encoder setups, and something as simple as a transitorized switch that makes the points low voltage / current. | ||

Reepicheep |

Other interesting factors... 1) Hall effect sensors are less precise than opto interrupters. I wonder how much? I heard 7% quoted, which sure seems like enough to matter. 2) I bet the existing pickup is not trying to do any spark advance, as all that is reprogrammable in the ECM. Doing it both places would be redundant and unwise. 3) The "6 posts per rotation" is a feature... it lets the ECM detect changes in speed before an entire rotation is complete. The spacing (which you can see from the trace) lets the ECM know when you have completed a full revolution (short space between pulse 3 and 4, longer pulse between 6 and 7 (where 7 is really the next 1 and it starts over)). My local electronics parts place has an optical interrupter in stock for $9. But it's only rated for 85 deg C. I'm guessing thats not a hot enough rating to be happy inside an Evo cam cover. | ||

Froggy |

Reepi, whats involved with removing/replacing the cam sensor? If it is no big deal, I can yank one off my 06 to loan you. | ||

Reepicheep |

You have to drill out the rivets on the cam cover. That in itself isn't awful, but its darn hard to do without ending up scratching the emblem that covers it. And if you pull it you then have to reset the timing. I appreciate the offer, but I already ordered one Saturday from my local dealer. They quoted a week, but hopefully it will come in sooner than that. So by the time yours showed up I'd probably be within a day of having the ordered part. If this is a Buell specific part, then so be it. But if the sporty uses the same part, shame on my local dealer for not stocking one. Al needs an east coast warehouse.  | ||

Froggy |

You should stop by garage some time, I pretty much am the east coast American Sport Bike with all the crap I hoard. | ||

Reepicheep |

OK, got the new replacement cam position sensor in. First, for $130, those cheap bastards at Harley didn't even include a new Deutsch connector. Sigh. Secondly, the instructions for taking said Deutsch connector apart are really unclear in the service manual. For the record, you do this: 1) Take a good grippy set of needle nose pliars and grab the center post (plastic with an arrow on the end) in the male side of the connector as close to the base as you can get, and yank firmly straight out. It will pop out. 2) You will then be able to see the little clips tha hold each pin in, and move them up, and pull the pins out. They are great little connectors once you figure them out (and if you have all the parts and the crimp tool). Though they do take up a lot of space. Anyway, I put in the new crank position sensor. It definitely fixed "something", as the tach now stops leaping forward. The bike is still running really badly though. I had to hook up ECMSpy to set the timing anyway, so i checked diagnostics. Hmmm. TPS sensor shorted to ground. OK, off comes the airbox plate, and look at the wiring. Oops. After my last engine rotation (rocker box gasket self induced error after replacing head from Corolla induced breakage) I routed the throttle cables wrong. I had the throttle cables over the wire bundle (where they look like they go when the engine is rotated down) instead of under the cable bundle (where they should obviously go once the motor is rotated back up). So the throttle cables (which were a little bit sticky at odd times anyway, something I noticed and should have pursued) had sawed through the fiber bundle armor. I could not find any evidence it made it through the cable, and yanking and tugging them could get no anomolous readings on the throttle position on ECM spy. Also, something rubbed on the TPS wires coming up off the throttle body, right between where the cable armor ended and the sensor plug began. It was not visibly through, but it was REALLY deep, so I'm guessing that was the short. I armored that up with split loom and cable ties as well. So now it's buttoned back up, and timed, and the TPS is reset. But it still runs lousy. At first, it was a sputtering stumbling mess everywhere, but after a few minutes it was sort of running OK at about 3000 RPM with a little surging. Still won't idle well though. All the ECM spy output appear rational. Wiggling ECM connectors makes no difference. So here are my current hypothesis and plan forward (in order)... inputs welcome. 1) The bike has fouled plugs from running really badly for quite a while (limping it home for 5 miles, diagnosing it in the driveway). And perhaps the ECM committed "fuelicide" trying to keep the poor bike running, and butchered some default offset for something. Solution: Put the neighbor with the truck on alert, and take a 10 mile ride holding about 3200 RPM or so, to let the ECM get unconfused, and to burn off junk on the sparkplugs. If that doesn't work... 2) Try and replace the plugs without rotating the engine (heard it can be done, I've never tried it), and drain and replace the gas with fresh gas (this started suddenly after a fillup). If that doesn't work... 3) In addition to ECM spy, use the digital scope to verify each ECM input, looking for transients that ECM spy may not have sufficient sampling rate to discover. This lets me remotely check a bunch of different sensors quickly... pretty much by just popping the seat off and putting a paper clip down each Deutsch connector hole. I don't think this will show me anything new, but it's easy. If that shows nothing... 4) Dig into the wire bundle that was stressed by the misrounted throttle cables and look for cracked wires again. I already fixed one previously that was caused by me wedging an aftermarket horn under the flyscreen and restricting that bundles movement when you sweep the bars. The throttle cable misroute could have induced another subtle crack somewhere. I could go pin by pin on the stuff coming from the bars, but you never know what you have to do to get the break to manifest, so unbundling and running each wire through your fingers looking for places where the copper is broken but the insulation is intact is the simplest method I have found. Even taking into account the time to rotate the engine down again. Plus that finds "about to break" wires as well as it finds "broken" wires. Hopefully it's just fouled plugs... can plugs foul enough to make an XB pretty much unable to idle at less than 2000 RPM or so? | ||

Reepicheep |

Update... Last night I popped out the front plug (which was dark black and furry, but not wet). These are iridium plugs... which I should probably just replace, but that I hate to just throw away. Seems like that on a 4 stroke, they ought to burn clean after a while, even if they are fouled. I also verified that I had correctly set the timing on the front cylinder compression stroke at TDC (or whatever the manual says). I had. I then fired it up (running badly) and took it for about a 5 mile ride. Over the course of that ride, it kept running better and better, but it still won't idle. It threw one code (O2 sensor always lean). The AFV setting went from 100% to 97% or something. The BAS reading was like 1.5 volts steady. The EGO voltage was .5 or something (all from memory, I should have written it down or logged it). Engine temps and ambient temps looked rational. I didn't put the scope on the TPS, but watched it in ECM Spy, where it looked smooth. But ECM Spy has a very low sampling interval, so I could be fooling myself here. I'll slap a scope on it soon. Riding it, when you are opening the throttle, it runs fantastic, stronger than ever. Reduced throttle to decel, its a mess (pretty much stalling). Steady throttle is hit and miss, and light on throttle is fairly reliable. I also re-did the TPS reset since the motor was warmed up. I didn't get far as I only had a couple hours available, and my cheapo ebay ECM spy cable broke, so I had to put that back together. By the end of the night it was running much better than when I started, but still clearly has issues. I also noticed that my idle adjuster... doesn't... So my next step will be to pull the airbox and baseplate back off, and track that problem down, and do a little more careful inspection of the throttle body (I previously got a code of TPS shorted to ground, and did see some wire damage that I addressed). I'll see what is stripped or broken on the idle adjuster, deal with that, and clean the throttle body of carbon (its a bit carboned up). I really need to switch gas also, just to get that variable off the list. Now I guess I'm up to the "check every sensor with the scope" phase of the project... which shouldn't actually be very hard, as they all come right up to the ECM for the most part. I should also really pull the ECM and re-do all the plug solder joints, and fabricate a support plate for that as well. Just to remove that variable as well. If I am sufficiently motivated, I should do a wire by wire summary of what the scope should see for the ECM inputs, and post them here. It would be a great diagnostic resource to have here on badweb... Print it out, get that $100 DSO Nano and a bent up paperclip, and rattle through all the relevant pins on the ECM and compare the waveforms with the bike running and off, and you can have diagnosed (or eliminated) a multitude of problems with just half an hour of testing... | ||

Hogs |

Reepicheep, all i can say is WOW After you get this sucker figured out, you will be the top Tech. in the U S of A.... You got to open a shop up eh.. LoL Good work for yourself and for all us here on this forum.... THANKS....   | ||

Reepicheep |

My write up makes it all sound much more professional than it is. Most of the time in the garage is spent wondering how on earth I could have lost that 1/4 inch ratchet with the T-27 head when it was in my hand 10 seconds ago and I haven't moved positions.  | ||

Reepicheep |

OK, started down the road of documenting all the sensors, but stopped for two reasons. First, the bike wasn't running right, and ideally I want to get the images both idling and not idling. Secondly, in the daylight, it was too hard to get good pictures of the screen. I may still do it though, it was a really cool exercise. | ||

Reepicheep |

Now for the good news... I believe I fixed the problem. The cam postion sensor (CPS) was indeed baked. It won't even get any signals on the bench test now. Got the new one and put it in, put things back together, bike ran like crap. Although something definitely improved... the tach no longer jumped *up* in RPM when the bike stuttered. And at WFO, the bike ran better than ever. Reset TPS and tried to burn plugs clean... got even worse. Pulled airbox plate and found misrouted wire bundle (my fault from head replacement) and chafing. Also chafing around the TPS sensor. Cleaned, patched, armored and rerouted. Still ran like crap. Hrrpmph. Pulled ECM and cleaned connectors out, double checked timing, still ran like crap. When researching how to test O2 sensor, I stumbled across the TPS reset instructions. Errr, I don't think I turned out idle screw. Aaack! re-did TPS ***correctly*** and tried it again. Yay! In hindsight, the 9600 baud sampling rate of ECM Spy does a great job of testing many of the sensors. Just not the crank position sensor. For that, the scope was really handy. I suppose transients on any of the channels might not show up in ECMSpy as well. Anyway, hopefully that's it! | ||

Reepicheep |

Have another 30 miles on it and no sign of the problem recurring... so far so good. | ||

Hogs |

| ||

Reepicheep |

Over 1000 miles, and no problem. I'm declaring this one fixed. | ||

Hogs |

So..Was it the wrong tps resting not backing out the idle cable... or the CPS... or both.   | ||

Reepicheep |

It was a bad CPS. The TPS was an unrelated and self induced sidetrack. When I replaced the CPS and was using ECM Spy to set the timing, that "reset TPS" button seduced me into clicking it. But I had forgotten to back down the idle screw all the way first, so instead of reseting the TPS, I was fouling up the TPS. That lead to a different set of problems, but once I realized it I backed the idle screw out, clicked the reset TPS button again, and all was again right with the world. | ||

Spd579 |

Is it possible to test the CPS with a DVOM? of is the frequency of the sensor too fast for the DVOM to pick up? | ||

Reepicheep |

You could probably use a DVM to test a completely dead CPS... if it never turns on even when turning the engine over slowly (a challenge on it's own) you know it is dead. And I suppose you could pull it out and use a steel screwdriver or something to try and turn on the hall effect sensor. But putting a scope on it really shows you clearly what is going on while the the problem is manifesting. |