| Author | Message | ||

Viper9885 |

Ok i realize that the crankshaft takes alot of abuse and i know its purpose and how it works and all that garbage. I am wondering though why it is shaped like a circle creating all of that heavy un-used, and very lightly stressed outer diameter. I would almost care to wager that you could take the crank and if you orient it so that the pin is at 12 o'clock you could cut 2 crescents out of it, one on each side to give it a almost hourglass shape, and shave BIG amounts a rotating mass and really not weaken it at all. Of course it would need to be re-balanced, but the cost of machining and balancing would be minor if you could eliminate say 5-8 pounds of rotating mass. | ||

Bombardier |

Viper, Check the difference of a Sportster crank to an XB crank. The XB crank looks positively anaemic beside it. | ||

Buell_bert |

I would think it is actually a flywheel and smooths out the power pulses. | ||

Jmr1283 |

i think its a very good ? viper. i mean i know when u start getting into 60degree twins u gain alot on the balancing. but ive seen a lots of cranks that have the look of a automotive crank but of course only for the first two cylinders. i would say Buell bert u just like to be a smart a$$ all the time. ive been on this site for a short time and i honestly havent seen u make a good comment to people once. whats ur deal. he said he understands the basics of this which includes the" very basic smoothing out power pulses" (dooaa). i ask why do u have to be so rude viper makes some very intelligent post on this site. which rate now i find him to be posting up some of the most interesting stuff. all i ask is why. | ||

Jmr1283 |

(rant...with a exhale) | ||

Viper9885 |

lol im flattered  | ||

Jmr1283 |

u post some very good stuff. very interesting. keep it up. | ||

Viper9885 |

im the type of person that can't leave well enough alone, if theres 2 pounds of material that doesn't NEED to be on that crank, why is it there? you know | ||

Jmr1283 |

i live for stuff like this. all i ever think about is motorcycle performance. i couldnt be further from a career in it though(carpentry) but my mind never wonders to far from the vtwim power plant. | ||

Buell_bert |

I just thought that if the flywheels were crescent shaped when the front or rear had its power pulse and then the opposite had there's would one or the other or both induce stress on the bearings, rods, cases or pistons. I am sorry my sentence was taken in the wrong context. | ||

Jmr1283 |

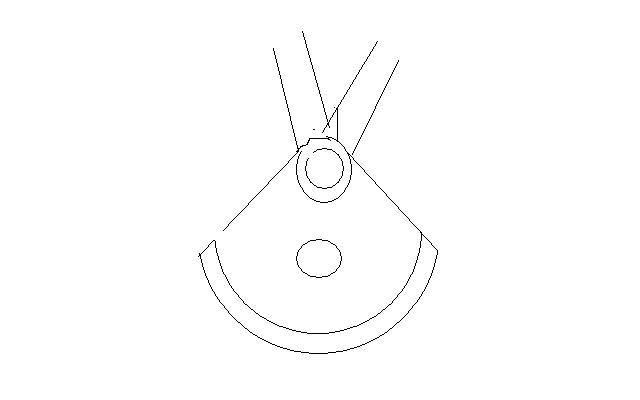

yah buell bert ive thought that too. but i thought with triangilation(sp?) from the crank pin to the a lower cresant that ud get the right pull and push u needed to flow throw the rough stuff. oh and buell bert no prob, it just sounded off to me. no personal stuff.  picture of my thoughts | ||

Strato9r |

Actually, the round flywheels, and their increased mass, do "smooth out the power pulses" in a manner of speaking. The circumferential mass of fully round flywheels has a greater tendancy to rotate at a more uniform rate throughout the engine's cycles, slowing down less abruptly during the compression cycle, and accelerating less rapidly away from TDC on the engine's power cycle. Jason brought up a very good point regarding the difference in mass between a Sportster crank assembly and a Buell item. The Buell flywheels are WAY lighter, and of course this is done so that the engine can rev up faster. Taking this a step further, and removing any mass from the crank assembly that did not have to be present to simply counterbalance the rotational mass of the piston/rod assembly or assemblies would seem like the next logical step. If you had a single piece forged or billet crank, it would be a far more feasable idea, as the metal making up the mainshafts, counterweights and crankpin are all one piece of metal, and as over a century of internal combustion technology has proven, this makes for a very strong crankshaft. Mass can be dramaticly reduced, to the point where balance shafts can be employed to cancel any undesirable primary or secondary vibration, and STILL have far less total rotational momentum than an assembled, flywheel type crank would have. One of the problems with this type of crank is that the crankpin, flywheels, and mainshafts are all separate items, assembled with a high degree of precision, and as an assembly, remain vulnerable to shock loads; just ask anyone who knows how to true up a set of flywheels how the tap of a brass hammer can move things around. Well, the inertial loads inside a V-twin are really intense, and if the smoother rotational dynamics that come with a pair of circular flywheels (and their higher mass) are not properly utilised, these things can shake themselves apart in no time. Even removing excessive weight from a fully round pair of flywheels can greatly reduce the life of one of these cranks, and everything attached to it! So, why use a crank like this? Well, if you see it as being a part of a mechanically and thermally balanced design, it makes sense. First off, we are dealing with an air cooled engine, and one of the limiting factors right off the bat is how much heat the cooling fins can radiate at peak output. At 7000 RPM, an air cooled Buell engine can ge rid of heat fast enough to keep the combustion chambers, exhaust valves and pistons from melting. Revving the engine much higher reduces time required between power cycles to keep things cool. So, you have an engine that can't rev much higher than 7500 RPM or so because it cannot get rid of heat fast enough, AND, the crank assembly is too massive to spin much faster without using exponentially greater amounts of power just to spin it any faster. The upside is that the engine is very efficient at lower engine speeds, requires only 2 valves per cylinder to provide sufficient airflow, can use maintenance free hydraulic valve lifters, requires no radiator, and can keep the EPA happy, without a catalytic convertor. Simple is good. | ||

Bombardier |

If heat is the enemy then the website by HP Coatings would be worth a look. It seems that their coatings on the internal faces of the combustion chambers and other parts would go a long way to making the engine more efficient. | ||

Strato9r |

Heat barrier coatings really do work well, and coating the inside of the exhaust port, and the exhaust pipe itself, is very effective at keeping exhaust heat from saturating the surrounding metal around the port. Inside the combustion chamber, however, it is possible to trap too much heat, bringing surface temperatures to the point where the incoming air/fuel mixture ignites spontaneously. If direct chamber injection, like the type used on diesel engines, was used, it could help minimize this phenomenon, but a further extension of all of this trapped heat is the fact that the exhaust valve cannot get rid of heat fast enough to avoid meltdown. The exhaust seat is the primary conduit for pulling heat away from the valve, and when the combustion chamber surface temperature nears that of the valve itself, the valve simply starts to burn away, or, heat will travel up into the valve stem, causing it to expand and seize in the valve guide. The other vulnerable point is the spark plug, which turns into a glow plug when it soaks up too much heat. A liquid cooled cylinder head can be designed to direct coolant around the spark plug and exhaust seat, making higher cylinder pressures possible. Oilhead Beemers and the new XR1200 Sportster heads use oil as a cooling medium to cool around the problem areas, and there have been air cooled diesel engines that have used supplementary oil cooling for years now. Heat isn't really the enemy until it starts to compromise mechanical reliability, and I've been following the progress of heat barrier coatings since the Hean Corporation started experimenting on piston coatings about 25 years ago. I think that if a "smart" coating could be developed, one that could be very reflective at lower load levels, then allow excessive heat to pass through at a pre determined temperature, it could really unlock the energy potential of the amount of fuel burned, since nearly 70% of the heat produced is wasted, even in the most efficient engine designs. | ||

Jmr1283 |

Rick thank you for all ur insight. very cool. Ive been doing research on the thermal coatings. my new project is a 99" 99 buell engine. and i want to gain everything i can out of it with out killing it. so any power i can make with out more compression etc.. why hasnt people gone into a way to cool the cylinder head +cylinders by coolant. u have a pump, water jacket cast into cylinders and head, then cooler. if this is the key to higher compression, more power, and rpms. then it would make since. is the market not there? | ||

Strato9r |

You're more than welcome, Josh, happy to pass on anything that might be of assistance. That 99 incher should be a wild one! In case you are interested, check out Page 20 of September's "Motorcyclist" magazine. There is a freaking AWESOME Brit style Cafe Racer with (get this...) a 135 Horsepower S+S 100 inch Sportster mill, (2 valves per cylinder, air cooled.........he he he...) As far as exotic, water cooled pieces for V-Twins , the history of that sort of thing goes back as far as the air cooled versions of these engines go. There is always someone with the tools and talent to come up with ways of making more power, but here is what often happens when these upgrades work better than anticipated. Let's say you come up with a really slick cylinder head that has a lot of breathing potential, and a really small combustion chamber as well. Now you can use a lighter piston, and spin that engine faster to fully exploit your new found airflow potential. Next thing you know, your power output jumps from let's say, 60 horsepower at 7000 RPM to 70 horsepower at 7000 RPM, but with all that extra flow capability and a lighter piston, you KNOW that you can twist this thing higher and make a bunch more power. Well, all of a sudden the crankshaft, bearings and engine cases are subject to exponentially higher stress loads, and react in a rather predictable manner, and the first weak link fails. You upgrade that, make a little more power, and the next weak link fails. You keep repeating the cycle, and soon enough, what you have is nothing like what you started with, it evolves into something completely different. There are plenty of examples of this kind of thing happening; vacuum tube circuitry evolving into transistors, then microchips. So, after all this evolution, who the hell would want to bother with any device with vacuum tubes? Guitar players and audiophiles, that's who, because nothing sounds like them. Sometimes, for a given application, the best technology is not the newest or most advanced. You could go out and purchase any number of fine machines that are V-Twins, and use liquid cooling, multi valve heads and everything that needs to be there to support the higher output of these engines. If I had the money, I'd have a garage full of Ducatis and 1125Rs and RC-51s, just so that I could experience a different flavor of screaming V-Twin any time I wanted. But, the bottom line is this: I could take out my air cooled 9r tonight, find a group of sportbike riders, and in the majority of cases, have THEM chasing ME in spite of lower peak horsepower figures and obsolete engine design and blah blah blah. Last Friday, when riding with a group of sportbike enthusiasts, we stopped for a breather before the last part of our ride, and some cocky little bugger on a CBR cracked wise about my obsolete engine. My buddy, who rides a GSXR told him he was about to find out what obsolete meant, and five of us took off at exactly the same time. It took four miles for my buddy and one cat on an R1 to catch up to me, and by that time we were back in the city again anyway. No sign of any CBRs, though. I look at that Sportster based engine and see a thing of beauty, simple, elegant, unencumbered by radiators and such. It does what it does very well, with extraordinary reliability, soulful response, and like a good tube amp, NOTHING else sounds like it! | ||

Jmr1283 |

Well my motor is t0rn completly down and im addressing all the parts in a way that there wont be any weak links. well this is a tough subject, because u could say that im using the stock s&s rods that come with the 89" kit, instead of the supreme rods, making it a possible weak link. but i think its good enough for my motor. The flywheel is prett damn heavy, and i was wanting knife cut the flywheel to loose some weight, but then i talked to my builder and switched to a windage tray and scrapper instead. oh and that s&s tribute bike was really nice. i find those dyno results to be a little suspecious. unless they did work on the engine, those 100" only put out under 110 hp and close to the same on tq. but minus the piston design and heads with there weird retainers with the holes all through it. i would love those cases though. lol | ||

Strato9r |

I seriously doubt that you will ever have any kind of problem with the S+S rods that came with the kit, so not to worry. Good call on the part of your builder regarding the windage tray and scraper. Best thing to do now is let him handle it the way HIS experience tells him, too many cooks usually spoil the stew! | ||

Jmr1283 |

nrhs does my machine work, and flywheel work. i assemble everything. its a good set up. My questions (lots and lots)with dans answers. | ||

Sweatmark |

This thread is a a deep well of cool, clear, logical thinking. Thanks for sharing expertise guys. | ||

Jmr1283 |

|