| Author | Message | ||

99x1 |

While changing a tire noticed the sprocket side bearing outer race could be turned in the hub. The diagram in the service manual doesn't match what is actually in the wheel - the wheels have shoulders on both sides, while the center (preload?) tube has no shoulders. The bearings had to be pulled out with a modified slide hammer puller. Bearings are being replaced and locked with Loctite 660 Pressfit. The outer bearing has no shoulder to be pushed against by the preload (and axle tightening), and would seem to be apt to spin...   | ||

99x1 |

Wheel was re-assembled with Loctite 660 Pressfit Repair on the drive side bearings, after cleaning with a white Scotchbrite pad and alcohol. The gel seems to lube the surface - the outer bearing was pulled in just using hand force on the axle, and the outer race seemed loose. Machinist/Mechanic told me to just leave it alone (with a spacer on the axle holding everything tight) for ~6 hours. Seems to work (only ~60 miles so far). I replaced all the bearings, but I think I could have just bonded the outer bearing back in (after a through cleaning). The 6205 bearings are readily available (and cheap ~$5 CDN), but the 62205 had to be ordered at $29 CDN. Loctite 660 also had to be ordered, and was ~$7 CDN. | ||

Jim_witt |

Hey John, I had a similar problem while on tour with my 98 S3T. Unlike you, I have the PM wheels. A shop up in Oregon repaired mine as you've outlined (new bearings/Loctite 660) to get me back to Arizona.  -JW:>  | ||

99x1 |

I put finger nail polish on the hub and bearing outer race so I could glance down and see if it spun. After so heavy weaving last night (from line to line, staying in my lane - like warming up the tires), the bearing had started to rotate. The Loctite has now broken free. Guess I will have it machined... | ||

Pilk |

How many miles before the bearing spin? is there a round about number when it happens or is it unpredictable? I'm at 10,000 and some change on my X-1 and dont really want to think about the bearings going bad or spinning in the wheel. Pilk | ||

Jim_witt |

Plik, Totally unpredictable in my opinion. -JW:>  | ||

99x1 |

Put a dab of nail polish or permanent marker across the hub and outer bearing race - the mark may creep for a while before the bearing starts spinning. I'm the 3rd owner of my X1, and have no idea if the belt was previously over-tightened, pressure washer used on bearings, or the bike abused. | ||

Jim_witt |

Yea, Then you can mount an inboard LCD screen on your dash and mount a boarascope to keep an eye out for the nail polish on the outer bearing race to see if it moves. Bet ya the metric engineers never thought of something like this. -JW:>  | ||

Philip |

had a new tire put on the rear wheel today and checked the bearings. aaarrrgggghhhh!!! the dreaded spun outer bearing syndrome! reading the posts about pm wheels it looks like the fix is a pressed in bushing. anyone had food luck peening or knurling and gluing in the bearing? man this sucks! | ||

99x1 |

I had no luck with gluing - ended up taking it to a machine shop (that said they did a lot of automotive wheels), they bored it out for $40 CDN. I machined a schedule 80 (thickwall) aluminium pipe for an interference fit (.003), pressed in with green Loctite 680 on the outer side. Metal SuperMarket cut a chunk of pipe into 2" lengths (and didn't charge for the pipe or the cuts). Has remained tight for about 2 years and ~10000 km. (Message edited by 99X1 on November 19, 2004) | ||

Philip |

thanks 99x1, it looks like machining is the way to go. how thick was the bushing you had made? i take it you had the wheel opened up too? thanks for the reply. philip | ||

99x1 |

(Disclaimer: I'm not a machinist, I just play) Yes, the wheel shop opened up the wheel bearing hole - I didn't have the equipment (or ability) to insure the hole was properly aligned. I don't have exact measurements, it's about 1/8" oversize? I had just bought a 6x10 model lathe, so I was kinda anal about making the sleeve - I machined a lip on the edge of the sleeve to an exact fit, took the chuck off the lathe (with the pipe in it) to test fit each time and then machined .003 over on the outside diameter. The inside of the lip was machined for an exact fit over the bearing, machined the rest of the sleeve .003 under, then cut the lip off. As can be seen in the pictures, it sits slightly proud of the wheel - I thought it might mushroom slightly while being pressed in, and I would cut it flush - but it didn't mushroom. Pretty tight fit, but it seems to have worked.   | ||

Philip |

cool. i talked to my behind me neighbor tonight who is a machinist and showed him my wheel. he said it is not so much the interference fit as it is the precision of the machining. of course his shop won't let him do any side work so i'll have to look for a shop that will do it. thanks for the feedback. philip | ||

Philip |

another problem. i removed the bearings in a very harleyish way with a brass rod and a 24 oz ball peen hammer. should have looked in he manual or in the knowledge vault! messed up the spacer between the bearings. parts guy at the local dealer looked it up and the book does not show a part number. the only way it is offered is with a complete rear wheel assembly. does anyone have a spacer laying around they can measure the overall length so i can make a new one? thank you for your help. philip | ||

V2win  |

Philip, When my rear wheel bearing loosened up because of the PM wheel, Buell sent me a new wheel. I had to pay $100 since I had the bike so long but they were real good about taking care of the problem. You might want to talk to East Troy, and your local Buell rep. and explain what happened. Be nice, polite, and accurate. Good Luck, John | ||

Philip |

thanks for the response john. i talked to the service manager where i bought the bike, a real good guy by the way, but he said he did not think they would goodwill it. your suggestion about calling buell is definitely worth the time. nice, polite are my middle names!!! i am not peeved about this at all except that i hammer headed the bearings out and beat up the spacer. a 24 oz ball peen in one hand and a chisel in the other is the only way to work on the ironhead! i guess these newfangeled scooters take more finesse. lol. thanks again..philip | ||

Bookyoh |

I checked the archives and have not found a failure like this. The left front wheel bearing on my 2000 M2 with 17,000 miles has come apart internally. I noticed a small line of grease on the axle, looked a little closer and saw the grease seal had popped off, looked yet closer and then saw the bearing cage was coming apart! I limped for about 10 miles then had to call a friend with a truck to carry my bike the rest of the way home. Has anyone seen this before? Thanks, Mark  | ||

Kdkerr2 |

Not on a wheel bearing. My BMW had failures of this nature in it's transmission but it had 114000 miles on it. I wouldn't worry about this. Just suck it up and buy some new bearings and consider yourself lucky that the front wheel didn't lock up on you on the Expressway at rush hour. Any product created by Man can be subject to premature failure. You should have gotten better service from it but that's life. Also there is the matter that the bearing was made in France which is suspect. Try to replace them with Timkens. However I have seen some Chinese made Timken Bearings. Good luck. KK | ||

José_quiñones |

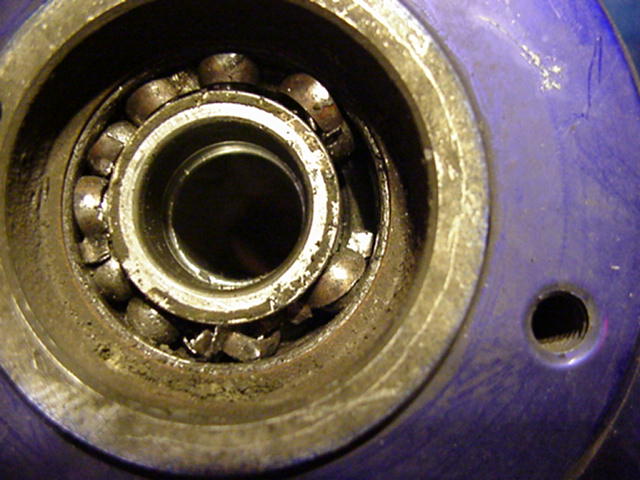

Fun with bearings.... I have had the same failure (same side of the wheel) a few times. It's almost getting routine at this point. You can get the bearings from your dealer or at a NAPA auto store, the NSK number for them is 6204-2RS. They are about $7 at the dealer, I think they are about $20 at Napa for some reason. Before you remove the bearings, check the inner spacer. Does is move around freely in there? It should not. The spacer should press against the inside of each bearing when everything is properly installed, it should not wiggle around too much in there. I think a cause of failures is that when this spacer does not press against the inside of the bearings, when you torque everything down you are putting "shear" or sideways pressure on the bearings from the outside towards the inside as you torque down the axle. The spacer is there to transfer that stress straight through across the bearings to the other side of the axle. If the spacer is shorter than it should be, you end up applying "shear" or sideways stress on the bearings before the spacer gets tight which is a no no. FYI, here's what my spacer looked like the last time I switched bearings recently.   You can clearly see how mangled the spacer was, it rattled around in there pretty good. When I installed the new spacer and bearings, the spacer was tight in there, make sure you line it up right before you press in the second bearing. The part # for the spacer is 41168-97Y (this is for a 99 S3), check your parts book/dealer to see if the number changed. You can do it yourself, with the right tool. To pull the bearings, find your nearest Autozone and "rent" their blind hole bearing puller, tool #27178. You pay $139 for it and get it reinbursed when you return the tool. To put in the new bearings, you could use a bearing/race installer (Autozone rents that too, $40). Whatever you use (a socket, the old bearings, etc) try not to strike the inside of the bearing (you're putting sideways stress on it). Always press/push on the outside bearing diameter. One trick that seemed to help was to put the new bearings in the freezer for a while. Then put a hot iron (with a towel) over the bearing hole on the wheel. The bearings will get smaller in the freezer while the bearing hole will expand with the heat, which should make the new bearings much easier to press in. Good luck! (Message edited by josé_quiñones on June 19, 2005) | ||

Bookyoh |

Jose: Thanks for the advice. Something seems very strange for this type of a failure. The bearing cage should be lightly loaded I would think. All the radial and most of the axial load should be taken up by the balls. It seems the cage only has to keep the balls properly oriented relative to each other. Once I have the bearing out, I will clean out the grease and take a closer look. The company I work for buys similar bearings so I think I will find out the next time one of the bearing reps is coming in and show it to him. I know we used to buy NSK and Nachi bearings; not sure if we buy SKF too. Mark | ||

Reepicheep |

Might it have anything to do with the fact that the service manual (or maybe the parts manual) has that whole assembly shown wrong on the exploded diagram? It was wrong in my 2000 manuals anyway. | ||

Al_lighton |

DO NOT hammer your bearings in. Even if you use a socket that is on the outside race only, do not beat them in. You can not maintain sufficient parallellism with the wheel when put in this way, and the subsequent wheel distortion will render the wheels useless for retaining the bearings. They must be pressed in, or use the HD threaded rod tool. I've tried using a generic threaded rod, it didn't work well. If you do use on, you must sleeve it so that the threaded rod remains perpendicular to the bore at all times. I don't like the threaded rod method because it is too slow. As Jose said, put the bearings in the freezer, heat the wheel. A press works much better because you can get the bearings in FAST, before the temperatures across the two materials can equalize. These cast wheels only give you 3-5 bearing swaps before the press fit interface starts to get questionable. Buy good bearings, not crappy ones. I have yet to see a Buell wheel with a made in USA or Made in Japan bearing in it. I've seen Turkey, France, Argentina, South Africa, Taiwan, and China, but no Japan or USA. Maybe the other nationality bearings are fine, but with only 3-5 swaps per wheel, I'll buy good ones. Al | ||

Djkaplan |

I've seen Turkey, France, Argentina, South Africa, Taiwan, and China, but no Japan or USA. An interesting aside to American bearings - I went out of my way to get Timken bearings (not the Chinese SKS bearings offered in most parts stores) for my truck and was surprised to see they were manufactured in Poland. | ||

Natexlh1000 |

My front left bearing went out in about the same way. It took 58K miles for that to happen though. Made a very loud squeek. I think I got away without the bearing spinning. It looks as if it dried out in there.  | ||

Buellistic |

BUELLers: Anybody ever think about poping the seals on these sealed bearing and regreaseing them !!! Have a 97S3T and regrease the wheel bearing as a PREVENTIVE MAINTENANCE SERVICE ... Still running my original bearings !!! In BUELLing LaFayette |