| Author | Message | ||

Ericx1 |

does anybody of you worldwide buellers ever had problems with the piniongear/oilpump transmission ?in may of this year i joined a trackday om my 99`x1 racing stripe:after the second session i rode into the padock with the engine ok. when i started it for the third session the oillight didnd go out so i stoped the engine again and checked the pressure switch:ok. i took the bike home and found out what was wrong;the piniongear was completly destroyed ;pieces of theeth broken of,some theeth were as sharp as a knife !results; oilpump scavagingside destroyed,gearcase contaminated with pieces of piniongear.i cleaned it all and installed a new pump and a new pinion gear. i checked the cranckshaft runout witch was less than 0,04mm(the buellbible says to replace with more than 0,05mm)so the cranckshaft is ok(bearings too). after placing the new parts the engine ran ok. i've rode it for 2000 kilometers and checked the pinion gear again; like new. so i am wondering what caused this. if it happened ten minutes later i would have blown the complete engine on the track. my buddy rides a 99 x1 also and he checked his pinion gear witch was strongly worn also. i dont know for sure but i think it has something to do with the hardening proces; the colour of the new pinion gear was more like bronze wile the destroyed one was more black. maybe some of you has an answer or an explanation or even the same experience? many thanks, Ericx1 | ||

Blake |

EricX1, Interesting account. That is the first such instance I've seen described here. Maybe others have some insight to the failure. glad it didn't ruin your entire engine! Wait a minute. Now that I really think about it, I believe that Ferris Bueller's S2 suffered a similar failure that did end up taking his engine with it. He hasn't got the Blur (his S2) back on the road yet though. His VFR has served as an ill equipped surrogate, blinding him to his true loss. | ||

Ericx1 |

Thanks Blake, i'm indeed very happy that it didnd happen on the track.in my modest opinion the transmision is chosen wrong if you count the number of teeth on the oilpumpgear its 20 and the piniongear counts 10.this means that every rotation of the crankshaft the oilpump wil rotate twice.so the same teeth will contact one another. this means wear!!! if this would be 19 vs 10 the same teeth would not see one another witch results in less wear. i am very suprised that nobody ever had problems with this.if you look at the oil pump you see that the gearshaft is kept in by a retainingring.the moment something hard comes in to the scavaging side of the oilpump(can happen during breaking in)the pump is locked and trough the rotation of the cranck shaft the gearshaft will be liffted.the only thing that keeps it down is the retaining ring. now there is an other side to this story: you can see this as a safety.under normal conditions there arent any hard pieces in the oil coming out of the gearcase.but the gearbox????? if you drain the oil from car gearbox (stickshift) you mosty find hard pieces!!! but anyway,this can by solved by putting a magnetplug in somewhere before the oil goes through the pump. since the system works oke,now there are no problems with it so i dont bother,but if you see this when you tear it apart you'de expect a beter construction for this.but thats my modest opinion. still currius about the hardening proces of the piniongear(that probebly caused all this) keep the oil pumpin, ericx1. | ||

Sportyeric |

I believe that one of the Pacific West Stormfront group had a similar failure last month on the SPLASH ride. | ||

Blake |

EricX1, Can you glean any hint of the failure mode from the failure surface? Are there any beach marks that would indicate fatigue as the culprit? | ||

Stevep |

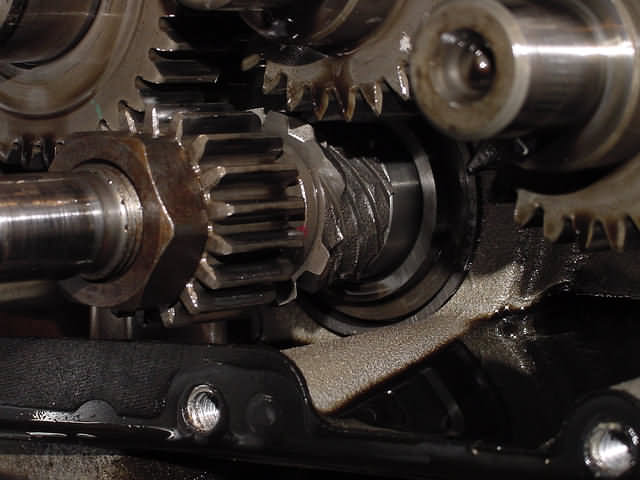

This is what mine looked at 19000miles.  SteveP | ||

Spudman |

Ericx1, Sorry to hear you're running into the same pain that hit me. I was on the SPLASH ride in July with my 99M2 (Sportyeric reference above). I was running with the fast group most of the day. On the last regroup stop before lunch the same damn thing happened to me. I shut off the bike while we waited. After about 10 minutes, the rest of the group catches up. I start my motor to take off and it sounds like someone threw a grenade in my cam gears. Then 10 seconds after the start oil light comes on and stays on. We were in the middle of nowhere so I babied it down it the mountain for retrieval. After I get it home and tear it down I find the pinion gear is destroyed, pic below.  Thought I was just an unfortunate soul who happened to get a bad pinion gear. But this sounds like others are having the same issue as myself. Thanks for starting this thread, thought I was the only one. I wonder how many other bad pinion gears have been replaced by the dealerships? | ||

Joem |

Any chance of seeing a good gear pic for comparo? | ||

Spudman |

Joem, The pic posted by Stevep above doesn't look too bad. But mine probably looked like that too at 19K. My pinion blew out with 21K on the odom. Work has been kicking my ass so I've had little time to play with my broken toy. I'll post a pic of the new pinion and old pinion side-by-side after I free myself of the work gorilla. Stevep, Did you replace that pinion at 19K? If so why? I can understand tires/brakes/clutches are disposables but the pinion gear should be good for the life of the vehicle. | ||

Ericx1 |

Thanks spudman, i also thought i was the only one with this problem.the dealer said never have heard of this, but thats what he always says if you come up with a problem! but when my buddy checked out of curiosity(and before a big trip) he found out he had the same pinion gear as shown above.that started my surdge for other victims. today i talked to an s1 owner who wanted to check his cams and he found a nearly destroyed piniongear also. i had to replace mine at 15k(ilometers) Blake, my piniongear looked similar to the one shown above only with at least 5 broken teeth.because of the teeth faling in to the scavaging side the oilpump locked, retainingring came of, pumpgear was pushed up(by the teeth left over)against the camgear!the moment the pumpgear was lifted the oilpresure fell of and the oillight came on.i never noticed anything strange( ecept the usual)knocking, or pinging. thanks guys for the compassion,wonder whats gonna be the next thing we dont expekt to be failing? since this happened i rode my toy to the spaninsh costas and on the way back for a quick snowski trough the french alps without any failure. so i'me satisfied for a while. keep up the good work. ericx1 | ||

Stevep |

Spudman, The pinion gear was found when I took the S1W in for an early 20,000mile servicing, had the mech. check the motor because I was hearing a Knocking from the front cylinder. They took the heads off and found the pistons and cylinder walls scored and thought it was from poor oil currlation. They then ordered the new oil pump and pistions, when they came in they found the pinion gear and also found that the roller bearings started to frag and chew up the crank pin. The motor was rebuilt under the extended warrenty and runs great. (even with loose spark plugs) SteveP | ||

Spudman |

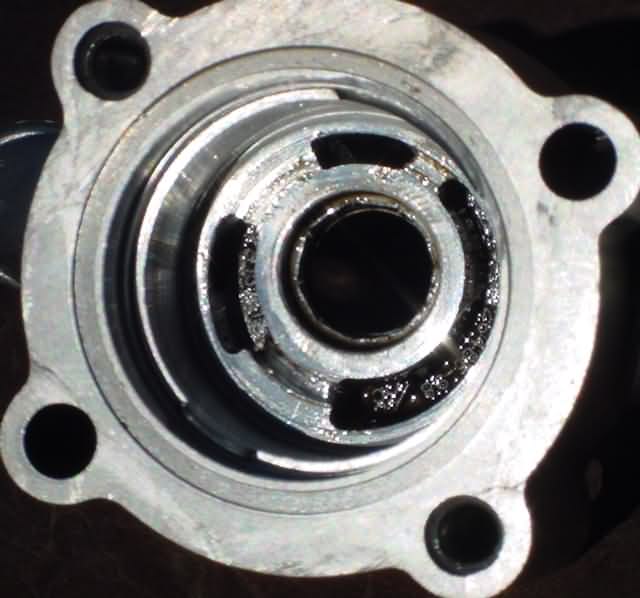

The new oil pump drive gear arrived today. Below is a side-by-side comparison of the old vs new gear. Not much left to the old gear. I took a bit of advertising discretion to show all the teeth that were pulled from inside the primary, different in every sense!  Some of the sheered teeth fell into the oil pump. They didn't get past the separator plate but they did do some damage to the scavage side. Amazing the amount of tourque it must have took to snap the feed gerotor set. They are now siezed together, a drive gear tooth can be seen sticking out on the right hand side of the pic below.  That tooth sticking out managed to spin inside the pump housing turning it into an aluminum paper weight. It's hard to see but there is now groves between the separate chambers. Probably couldn't generate much return pressure in this condition.  Not sure how much longer the rest of the engine is going to last. But I'll patch it up tonight and run it till it blows. Below is an overview of the costs. New Oil Pump Drive Gear.....$15.00 New Oil Pump...............$165.60 Misc Gaskets.................$9.70 Fresh Oil and New Filter....$22.42 Sharing with the world....priceless | ||

Smokin84 |

Hey guys, Zipper's makes a silicone-bronze oil pump drive gear for "Use in extreme load applications such as Buell road racers and top fuel dragsters." part#613-142 About $50. I am going to run one in mine just cuz. | ||

Ferris |

Wait a minute. Now that I really think about it, I believe that Ferris Bueller's S2 suffered a similar failure that did end up taking his engine with it. i'm late to this dicussion, sorry. the BLURR did indeed suffer similar probs, altho my theory about my stripped pinion gear (which looks IDENTICAL to Spudman's above), is that a piece of broken wrist-pin clip falling down into the crankcase got into the oil pump and wedged in the gerotor (which looks IDENTICAL to Spudman's above), locking it up and then taking the pionion gear out. i had a rear intake leak that i missed, and after a high-speed assault across the Mojave Desert on a hot July 3rd afternoon, i believe the rear piston got hot enough to deform enough to let one of the wrist-pin clips escape. the resultant carnage was significant, but i'm not prepared to say it was a result of anything other than way too much engine heat because of the holed intake seal. Spudman, i gotta tell ya, it looks like you took pix of MY busted-up engine parts! also, in my case it seems REAL obvious that the fragment of metal that did in my gerotor (again, mine looks JUST like yours, including the crack in the outer housng) is a piece of wrist-pin clip; is there any chance that THIS may be the cause of YOUR problems? FB | ||

Ferris |

I took a bit of advertising discretion to show all the teeth that were pulled from inside the primary, different in every sense! btw, have i ever told you what a sick puppy you are?  FB | ||

Ferris |

His VFR has served as an ill equipped surrogate, blinding him to his true loss. ill-equipped it ain't, surrogate it may turn out to be (see the GDB for my '03 Lightning blathering), blind i occasionally am, and the loss, altho large, is only temporary -- the BLURR sits patiently in the garage, engine out, waiting only for the financial stars and planets to align  FB | ||

Blake |

"ill-equipped it ain't" Don't tell me you've fallen in love with an appliance.  | ||

Blake |

Spudman, Great pics. Thanks for sharing. Allen, Is the silicon bronze supposed to be stronger, or just more durable. I can't imagine bronze being stronger than steel. See my post on the drag racing page. I suck at drag racing! I need to get Richard to give me some instruction. At least I finally learned how to ride a wheelie.  | ||

Ferris |

Don't tell me you've fallen in love with an appliance. ever ridden one? FB  | ||

Edv |

I just pulled down a customers 98 S-3 and the oil pump drive gear was worn 1/2 way through the teeth the same as the ones pictured above, obviously there is a problem. Ed | ||

Jprovo |

FYI Buzz Buzzelli noted this failure in his book "H-D Sportster Performance Handbook". The bronze gear may help prevent galling and actually have a better lifespan than the steel (iron?) gear, then again, it's not like I've tested it. | ||

Blake |

FB, No. And you can't make me.  Jprovo, Galling? Bathed in oil? | ||

Jprovo |

Blake, I don't know it it is galling or not, I just know that the gears show abnormal wear. The gears out of my '75 sportster didn't look that bad when I replaced the oil pump gears. SteveP's gear doesn't look like it suffered from too much lubrication  , how much of an "oil bath" is in a dry sump (Sportster/Buell) motor? , how much of an "oil bath" is in a dry sump (Sportster/Buell) motor? Most 90 degree helical gearsets that I've seen (speedo drives, distributor drives, industrial machinery) have gears of differing materials like nylon & steel, bronze & steel, or Iron and Steel. Bronze is a typical helical gear material because it is more durable and is quieter than steel (I don't have proof of this, just input from people who work on helical gear driven pumps). I don't think that power transmission loads are going to be much of an issue so the bronze gear should be fine. But of course, I haven't calc'd anything out, I just trust that Zippers knows what they are doing. | ||

Blake |

Agreed. | ||

Rempss |

According to Zippers on the silicone-bronze oil pump drive gear #613-142 upon asking for price & avaialability:

Spud, What is the part # on the HD replacement unit? Jeff | ||

Reepicheep |

How hard would it be to get in and inspect the pinion gear? I am looking at the service manual for my Cyclone, and don't see clearly where it sits. Is it a part of the pump (that drops off the bottom of the engine easily), or do you have to pull the gearcase cover to get at it? From there is it just a nut to get the rest out? Probably worth a visual inspection.. but I have never had that side of the engine apart and don't know what all is involved. | ||

Rempss |

Reep, Check out the X1 Files - here Jeff | ||

Reepicheep |

Thanks Jeff... sounds like you can remove the oil pump and look up into the whole to examine the pinion gear. I assume replacing the pinion gear requires pulling the gear cover, but that does not look any worse of a job then pulling the primary cover. | ||

Mikej |

"but that does not look any worse of a job then pulling the primary cover" You've got to relieve the tension on the push rods, which may entail popping the rocker covers off and loosening the rocker assemblies. Some say you can get the gear cover off without touching the top end, and others say maybe with perfect alignment and a lot of care and experience and patience when you go to put it back on again. Basically, them cam shafts are a snug fit to the bushings in the cover. A bit more work than removing the primary cover. | ||

Bomber |

you CAN remove and replace the cam cover without disturbing the top end at all, but only if you do it before reading that you shouldn't!! |