| Author |

Message |

Jmartz

| | Posted on Thursday, August 08, 2002 - 11:54 am: |

|

These discussion/argumets serve us wellwhile we put in our time at work in front our computers. Personally I have so many things to be serious and precise about that motorcycle issues and public policy need to fall in the "enteretainment" category so I can enjoy them. |

Torqd

| | Posted on Tuesday, August 13, 2002 - 10:15 am: |

|

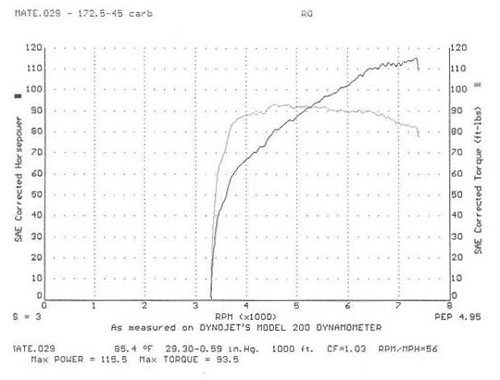

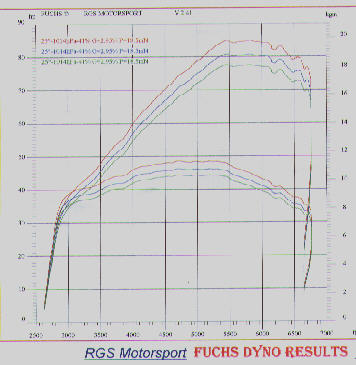

Mark Sidwell...Atlanta,GA

Nallin Stage 3 heads & 1250 kit

Nallin Racing Ported Intake Manifold

Redshift 585V2 Cams

Jim's Hydrosolid Lifters

Nallin Racing/Force Motor Products Big Bore Race Pipe

Mikuni HSR45

Dyna 2000 Ignition

These numbers keep getting higher and higher! That makes at least half a dozen out there with Brians stuff that makes 110+hp and 90+ft/lbs...then this standard fair setup makes 115...this is getting cool...Who would have thought that 3-4 street buells(This one, Aarons and Smaddens)would be running around with 115hp...not me. Congrats to all. Now I just hope that my 88 will be together soon so I can get some numbers out of that:-}

|

Aaron

| | Posted on Tuesday, August 13, 2002 - 10:20 am: |

|

NICE!!!

Interesting that he's running an HSR45 on that small of a motor ... hmm ... I just *happen* to have one laying around ... |

Torqd

| | Posted on Tuesday, August 13, 2002 - 12:24 pm: |

|

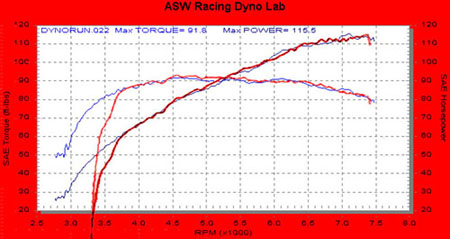

give it ia try and let us know how it works...just for kicks I put your dyno and this one together...look similar to you??

|

Aaron

| | Posted on Tuesday, August 13, 2002 - 12:35 pm: |

|

Wow, that's amazing. |

Blake

| | Posted on Tuesday, August 13, 2002 - 04:36 pm: |

|

Torqd,

How'd you do that?

On the dyno results... To be fair, Aaron's is stock displacement where Mark's is a 1250 big bore. I'm wondering why Mark's dyno run wasn't started at a lower rpm. Maybe the HSR45 didn't like running at lower revs? |

Torqd

| | Posted on Tuesday, August 13, 2002 - 05:36 pm: |

|

Well I used Photoshop and matched up the lines and rpms...I do it all the time to see how the curves compare...I know that it is 2 different bikes at two different places and all that ...it is just a look at things...and yes it is a 1250 but it also has fairly standard pair of heads on them...nothing outside the box:=) The real cool part here is not who has the biggest numbers but that these numbers are achievable by everyday people and with readily available parts (at least with Brian's packages...I don't know about Aaron's heads being readily avalible:+) |

Blake

| | Posted on Tuesday, August 13, 2002 - 08:56 pm: |

|

Oh yeah, I agree. I just want to be sure everyone understands the comparison on an apples to apples basis.

Cool photoshop work! |

Pammy

| | Posted on Tuesday, August 13, 2002 - 10:05 pm: |

|

Ya'll aint seen BAD yet....but it's comin'... |

Blake

| | Posted on Tuesday, August 13, 2002 - 10:39 pm: |

|

Pammy,

Will "BAD" fit into a Buell X-Frame?  |

Torqd

| | Posted on Wednesday, August 14, 2002 - 01:55 pm: |

|

how long???? and where is it coming from:-) |

Snowdave

| | Posted on Saturday, August 17, 2002 - 07:42 am: |

|

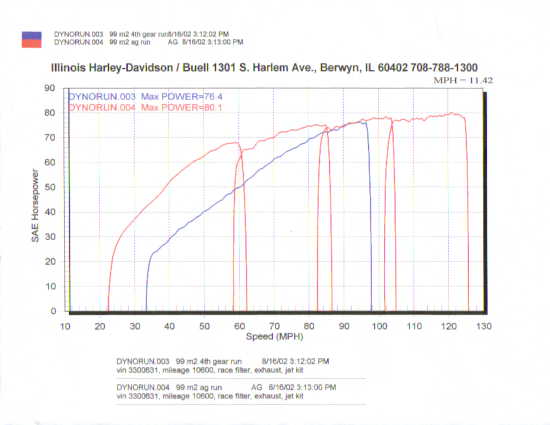

Well, these don't compare to all of your 100+ HP postings, but I want to get some feedback.

Specs

1999 M2

Race Exhaust

Homemade race air cleaner

Nology Wires

Yost Power tube (42, 165)

Thunderjet (100)

Rerouted Breather lines

Otherwise completely stock

I was very happy with how smooth the torque & HP curves are - I have tuned the hell out the carb system. The tech said he wouldn't change the jetting at all.

However, I was disappointed at the peak numbers. I realize that fastest way to get improvements are cams & heads, but I thought the exhaust & intake with proper tuning would get me much higher than this. Although I just noticed that they stopped the test 5800 RPM. Is that why my HP is not where I expected it? I think my redline is 6800, so is there more power higher up?

Any input is greatly appreciated. However, I will not be adding heads or cams since my M2 race bike arrived Thursday and it blows this one out of the water for power. I will post it's dyno later after I have a chance to catalog all of the specs.

One more comment, the bike had about 30 minutes cool down after being ridden for 1.5 hours in city traffic. I don't know if that is long enough or the results were affected by the heat. |

Blake

| | Posted on Saturday, August 17, 2002 - 02:18 pm: |

|

Dave,

That torque curve looks good. Your 2nd plot shows that indeed the HP was still climbing well past where your first plot run was stopped. Must be a Harley-only guy running the dyno; they don't always know the Buell rev limit is higher than that of a sportster. A peak of 80 RWHP is very good for a '99 M2 with stock sportster cams, and your torque curve is nice and fat. Check out some of the other close to stock M2 dyno plots for comparison. Yours stacks up very well. |

Freyke

| | Posted on Monday, August 19, 2002 - 09:17 am: |

|

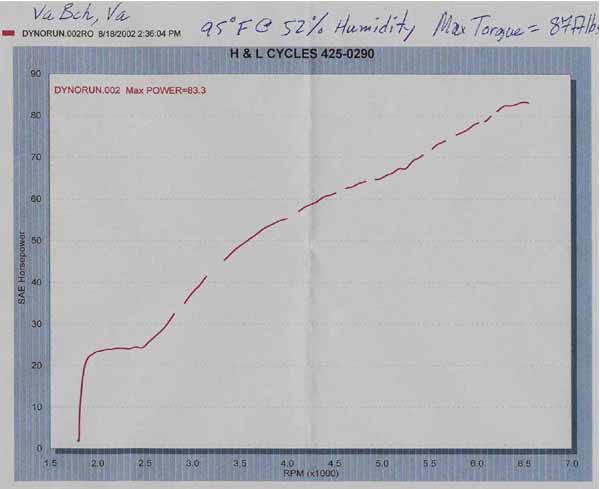

It was very hot and humid out at the time of this Dyno Run... It was also a $30.00 special. (all you got was the peak HP and no torque trace).. The fella did show me the torque trace (Max. 87ftlbs) but I do not recall the RPM it occured at... My bike is pretty mild as far as mods go... click on profile to the left...

Can anybody correct this for a 72 degree day @ 30% humudidty... this dyno run was also done on 92 Octane unleaded at approx 20Ft. MSL...

kk//kef |

Aaron

| | Posted on Monday, August 19, 2002 - 09:46 am: |

|

Looks to me like it's already corrected ... it says "SAE Horsepower". |

Freyke

| | Posted on Monday, August 19, 2002 - 01:34 pm: |

|

Aaron,

I don't belive it is corrected, I think the SAE measument means it was taken @ the tire vice the flywheel/crank... but not corrected temp/humidity at for optimal conditions... As the fellow running the dyno said "you'll do better on a cooler day with less humidity"... He said on average most bikes would loose about 8HP in these/those conditions... but that was just a ballpark number he through out.... |

Blake

| | Posted on Monday, August 19, 2002 - 02:27 pm: |

|

Copied from GDB... (what'samatta Freyke, feeling ignored?)  This is the place for your dyno plot; thanks for posting it here. This is the place for your dyno plot; thanks for posting it here.

Freyke,

Your plot shows SAE HP, so it is already corrected (like Aaron already pointed out above).  The 87 FT-LB torque you were told does not add up. You can calculate the engine torque (T) by simply reading HP and dividing it by the corresponding RPM then multiplying that result by 5252 (T=HP/RPM*5252). For example, at 3500 rpm you have about 50 HP, the engine torque is then... The 87 FT-LB torque you were told does not add up. You can calculate the engine torque (T) by simply reading HP and dividing it by the corresponding RPM then multiplying that result by 5252 (T=HP/RPM*5252). For example, at 3500 rpm you have about 50 HP, the engine torque is then...

T3500 = 50/3500*5252 = 75 FT-LB

Or at 6300 rpm you have about 82 HP so torque there is...

T6300 = 82/6300*5252 = 68 FT-LB

And of course at 5252 rpm the torque equals the HP; your HP plot shows about 67 HP at 5252 rpm.

I'd be skeptical of any dyno operator that does not provide a torque plot along with the HP plot. He measured your rpm and therefore already had the torque available to include in your plot. He simply chose not to plot it. |

Aaron

| | Posted on Monday, August 19, 2002 - 03:34 pm: |

|

Freyke, if you can get your hands on the DYNORUN.002 file and send it to me, I'd be glad to generate a chart with torque for you. I should also be able to examine the correction factor and the weather conditions it was calculated against. I can even show you STD, DIN, EEC, or uncorrected results, all of which will give different answers.

FWIW, I actually tend to get a little better corrected results on hot days for some reason. But yeah, humidity tends to bring it down. The whole correction process is imperfect, and from what I hear, the Dynojet implementation of it is incomplete to boot. For example, oil temp is supposed to be a part of it as well, but the Dynojet makes no attempt to measure it. |

Freyke

| | Posted on Monday, August 19, 2002 - 06:21 pm: |

|

Aaron...

No such luck... no disk no nothing... just a sheet of paper....

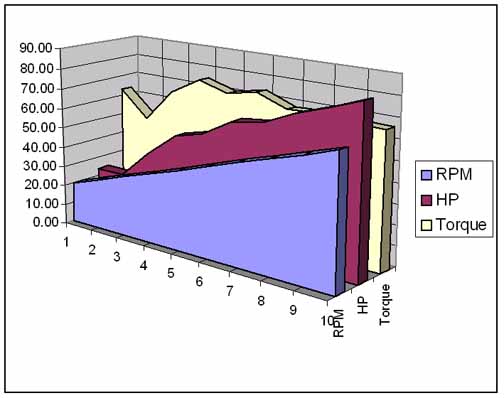

But, using the formulas provided by Blake I took the HP plot I had and wipped up the following in excel...

|

Freyke

| | Posted on Monday, August 19, 2002 - 06:23 pm: |

|

Aaron... Let me try this again....

No such luck... no disk no nothing... just a sheet of paper....

But, using the formulas provided by Blake I took the HP plot I had and wipped up the following in excel...

|

Archer

| | Posted on Wednesday, August 21, 2002 - 11:25 am: |

|

Has Anyone posted a dyno chart for the XB9R with the race kit yet??? If not COURT?? Do I get a t-shirt for posting the first? |

Petel

| | Posted on Friday, August 23, 2002 - 06:34 am: |

|

Hi guys;

I`d like your opinion on this dyno chart.

The bike is a UK 2002 M2.It`s running a G-Force race oval can,Dynojet kit using the #195 main and at the time a standard airbox!

When I ran it with the #190 main it lost 2hp at 4000rpm and 1.5hp at 5500rpm.There was a dip in the curve at 4000rpm that disappeared when I fitted the #195.

Question is it flattens out at 5500 when it should run to 6500.Is this due to the standard box?

Also the dip in both torque and hp at 6200?

Is this the standard ignition modules way of telling you to back off?

Thanks.

Petel.

Whoops :-) Er it`s down there vvvvv.

vvv

v |

Petel

| | Posted on Friday, August 23, 2002 - 07:12 am: |

|

C:\My Documents\my pictures

dyno 3 dyno 3

The second run using the #195 main jet. |

Petel

| | Posted on Friday, August 23, 2002 - 07:31 am: |

|

C:\My Documents\my pictures

dyno 2.jpeg dyno 2.jpeg

This was the first run using a #190 main.

Notice the dip at 4000 and the dive at 5500.

The above run using a #195 was definately better.

I`m hoping the airbox and breather mods I`m working on at the moment will get the peak up to 90hp at 6200.

Any ideas what`s causing it to dive?

These runs were with a standard airbox!

Thanks.

Petel. |

Hootowl

| | Posted on Friday, August 23, 2002 - 09:42 am: |

|

Are you using the stock M2 cams? |

X1glider

| | Posted on Friday, August 23, 2002 - 10:23 am: |

|

Pete: The charts look good for what you have. I'd expect nothing less.

The stock cams in your M2 are the same as what comes in the Sportsters. Designed for good low end and midrange pull. The stock cams have very little overlap if any and low duration which allow it to build cylinder pressure with a fairly low compression ratio. The stock cams weren't designed for top end breathing. The lightning cams have more lift, duration and overlap to allow better top end breathing, but unless you increase the compression ratio a bit, you'll lose some bottom end torque because the exhaust valve will be letting air escape and the cylinder can't build enough pressure to make power. A free flowing exhaust such as yours won't help that either. The air box is not the problem at all, it's the cams. A boost in compression would help too if you have the cash. They go hand in hand.

Bob (Never cesasing to learn from my own costly mistakes) |

Aaron

| | Posted on Friday, August 23, 2002 - 10:52 am: |

|

At least through '01, Euro M2's came with Lightning cams. I don't have a 2002 parts book, so I can't say for sure about them.

Don't mean to pick on anyone here, but loss of compression with longer duration cams is a function of the intake valve close point. The exhaust valve closes very early in the intake cycle and is closed throughout the entire compression cycle, it has nothing to do with it. |

X1glider

| | Posted on Friday, August 23, 2002 - 11:32 am: |

|

What about the exhaust valve close point? Why wouldn't that bit of overlap when the intake cycle starts let enough air to pass through the exhaust valve possibly lowering the effective compression ratio, say, down to 8:1? Since putting more radical cams in my FXDX with a 9.5:1 CR, I'm guessing the low end torque dip problem I have is actually caused by my cylinders not building enough pressure until I wind it up. I'm not sure that my exhaust is the problem at all. I know, too many other variables...but I'm still trying to trace my path backwards.

Bob (Still learning, this time on the info hwy for free)

BTW, Aaron, have you ever used services from Dragon Precision Machine in Colorado Springs? A friend of mine with a Pan/Shovel project needs some case and head repairs. I see the ads a lot but just not aware of their reputation. |

Aaron

| | Posted on Friday, August 23, 2002 - 11:58 am: |

|

The exhaust closes as the piston is starting it's downward journey, taking in it's next fuel charge. The intake valve is simultaneously opening as this is happening. The engine can't bleed off any compression at that point, it's quite a ways from even starting it's compression stroke. Hopefully it actually has a little vacuum going as the exhaust valve is closing, sucking in the next fuel charge through the rapidly opening intake valve.

Where the compression gets affected is a little bit later, when the piston gets all the way down and starts back up on it's compression stroke. The intake valve actually closes after the piston starts it's upward journey. This is the critical event because until that intake valve gets closed and seals the chamber, you can't build compression. The later you close it, the more compression you bleed off, and the higher compression ratio is needed to get good compression. Rule 1 of cam selection, match the intake close event to the compression ratio.

Here are some intake close event comparisons (approximate numbers ABDC, .053 lift):

Stock M2 cams: 40 degrees

Lightning cams: 48 degrees

Red Shift 585's: 58 degrees

the cams in my 100" race motor: 70 degrees |

Aaron

| | Posted on Friday, August 23, 2002 - 12:18 pm: |

|

Oh yeah ... on Dragon Machine ... I've never used them but I've sure heard a lot of horror stories. |

|

»

Buell Dynamometer/Dyno Testing Archives »

Archive through August 23, 2002

»

Buell Dynamometer/Dyno Testing Archives »

Archive through August 23, 2002

»

Buell Dynamometer/Dyno Testing Archives »

Archive through August 23, 2002

»

Buell Dynamometer/Dyno Testing Archives »

Archive through August 23, 2002