| Author | Message | ||

Whodom |

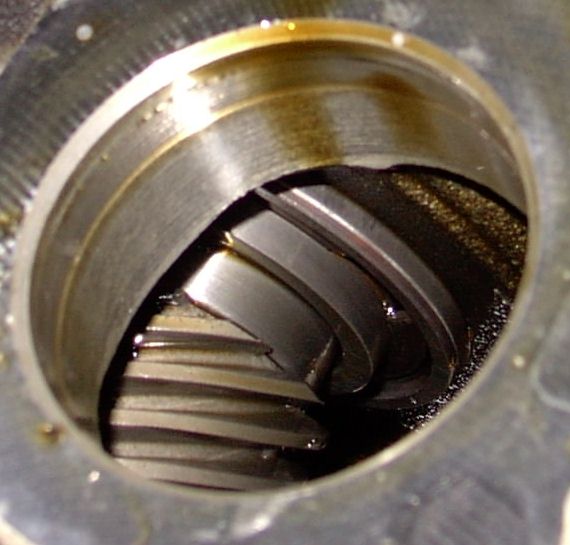

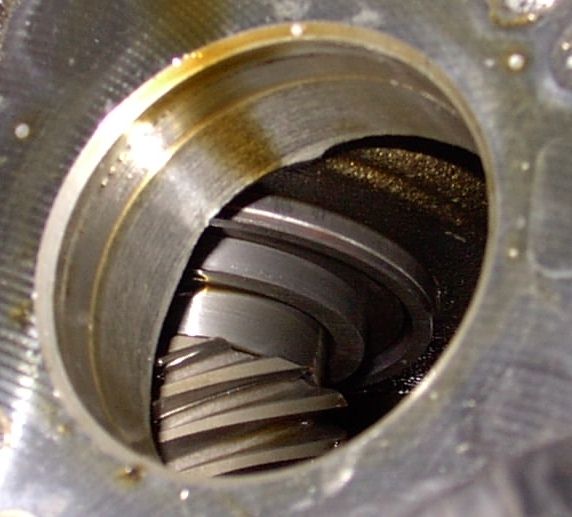

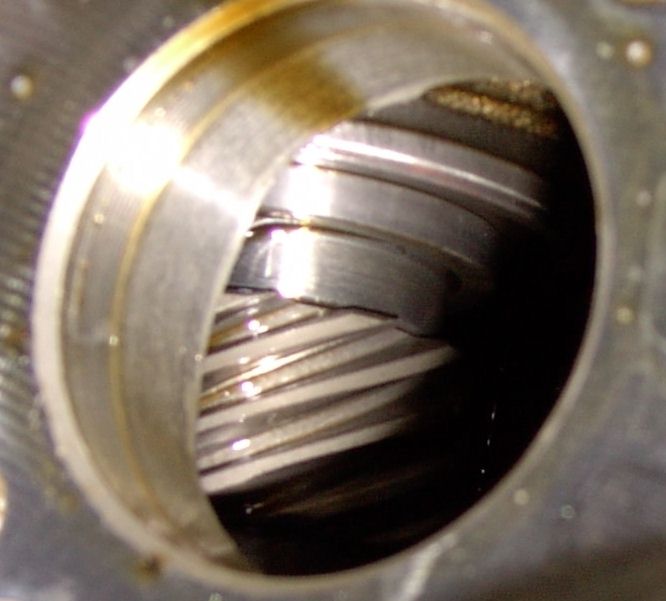

I acquired a 2000 S3 about a year ago and as I dug around on this board for relevant info, I found two or three threads regarding problems of abnormal wear with the gear that drives the oil pump. Here's the URL for one of them: http://www.badweatherbikers.com/buell/messages/3842/19693.html My bike turned 11,500 miles this week and was due for an oil change, so I dropped by the dealer yesterday and picked up an oil pump gasket and new filter so I could take care of it. This morning I dropped the pump and here's what I found:  You can see that the teeth towards the bottom of the photo look perfect, while there is noticeable wear on the tooth at the top.  As I rotated the engine, you can see more wear on these teeth.  As near as I can tell, only 3 or possibly 4 have any visible wear on the drive gear. I also checked the driven gear on the oil pump itself, and while no wear was evident, you can clearly see that the two gears do not engage fully:  You can see on the gear teeth at the right side of this photo that the drive gear is only engaging about 50% of the area of the teeth (towards the bottom of the photo). See Whitebuell's post in this thread http://www.badweatherbikers.com/buell/messages/3842/14795.html to see how he corrected this on his bike. I didn't think the wear on my gear looked excessive, so I buttoned things back up, but I plan on inspecting again in not more than 5000 miles, and I suspect I'll be changing the gear then. (Message edited by whodom on June 25, 2005) | ||

Reepicheep |

Rumor from my local dealer is that you can replace the cam cover without pulling the rocker box if you get the cams in the right places at the right time. If that is true, then it would not be a huge deal to replace the drive gear. If that oil pump gear goes, the engine is likely toast in about 5 seconds. I would not spend much time waiting for it. Great shots! A $150 Ebay special coolpix 950 should be in every garage. | ||

Kdkerr2 |

Several years ago I had an oil pump failure which was caused by a lifter failure on my FXR. There was about 28000 miles on the engine. The lifter needle bearings fell down into the sump and then were sucked into the pump. There is no filter screen on the big twins to keep such crap out. I was on the I-65 at the time when the red light came on meaning no oil pressure! I drove about 5 miles to the next exit and my engine didn't seize up. I was sure glad I didn't have to drive any farther. I've since learned that lifter failures on Evos and Shovelheads aren't that uncommon especially if you're running a high lift cam and aftermarket heavy duty valve springs. KK | ||

Whodom |

Reepi, I guess that would be with all 4 valves closed? Doesn't seem like it would be that hard to figure out. Al Lighton says he is checking several bikes for this in the near future and is still trying to determine the root cause of the problem. Seems like with all the Sportys and Buells out there, it would have been nailed by now, or is it really not that common of a problem? | ||

Steveshakeshaft |

Seems from what I've seen here, it is a "build up of tolerances" issue? Regards Steve. | ||

Whodom |

Steve, That could explain the fact that the oil pump gear does not protrude into the crankcase far enough (so that the middle of the oil pump driven gear is slightly below the centerline of the driving gear) but it doesn't really explain the wear pattern on the driving gear itself. It looks like every one of these that's had a problem has wear on less than 50% of the driving gear. This seems to indicate (1) the driving gear was machined off-center, (2) the hardening of the driving gear is not uniform ("soft" spot on the gear), (3) if the driving and driven gears have a 1-to-1 ratio, the driven gear could be off-center causing the driving gear to wear like this or (4) something we haven't thought of yet. See the earlier threads here: http://www.badweatherbikers.com/buell/messages/3842/14795.html and here: http://www.badweatherbikers.com/buell/messages/3842/19693.html | ||

Whodom |

I'm trying to do a little further research on this problem. I thought I had read (or maybe I just assumed) this was also an occasional problem on Evo Sportsters, but I can't find any reference to oil gear problems on Sportys on the net. Has anyone heard of Sportsters having this problem? | ||

Steveshakeshaft |

Whodom, a "build up of tolerances error" may also include slight misalignments or eccentricities. Without such a "build up of tolerances" error those factors may not be significant, but putting the several factors together, may give you a problem? I haven't seen much of these "in the flesh" but there is, it seems, a problem there for the diagnosing. In my experience, problems with machinery often result from a combination of circumstances. Each one on its own maybe not a problem. But put them together...... Regards Steve. www.shs-consulting.co.uk | ||

Al_lighton |

Hugh, Since we corresponded last, it occurred to me that the statement "if the driving and driven gears have a 1-to-1 ratio, the driven gear could be off-center causing the driving gear to wear like this" isn't precisely correct. It doesn't have to be 1-to-1 ratio, just an even multiple, to cause an out of round driven gear to wear the same teeth on the driving gear. If the driven gear (the oil pump)has exactly twice as many teeth, then if there was an off center driven gear, the close (or far) teeth would mesh with the same teeth each time on the driving gear. I just counted. The oil pump gear has 20 teeth, the oil pump drive gear has 10 teeth. Exactly 2 to 1......Hmmmm. Al | ||

Reepicheep |

This came up before... When you drop the oil pump to inspect the gear, rotate it 90 degrees before reinstalling... just in case. | ||

Al_lighton |

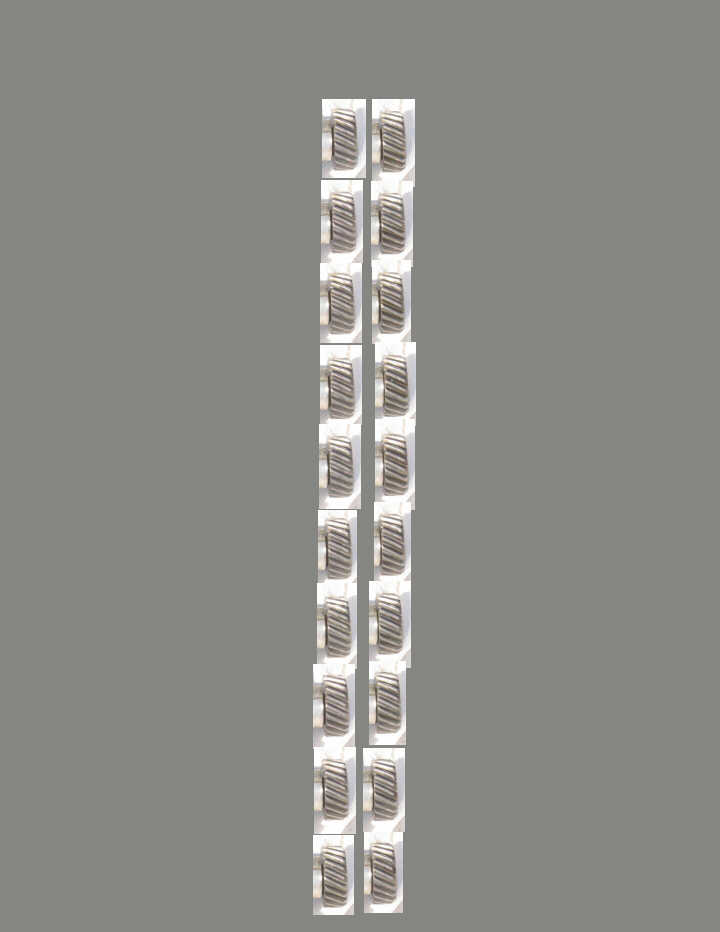

Just dropped the pump on my 99S3 with 27,456 miles on it. Here's a few shots:       Here's a collage of the oil pump gear from my 98S1W that had the VERY worn and just about ready to frag drive gear, the first 10 positions are shown right next to the second 10 positions  It isn't perfect, but it isn't worth yanking at this time. It's in pretty good shape overall. First time I'm in the rocker box area, I'll probably yank the cam cover at that time. The collage pictures are too small to see, but the wear pattern on each of the oil pump gears are identical to the one halfway around (10 teeth later). Not sure, but this would seem to indicate to me that the assymetricality is in the drive gear, not the oil pump driven gear. But I don't have a PhD in Forensic Gear-ology, so I'm not positive that is a correct conclusion. Al (Message edited by al_lighton on June 26, 2005) | ||

Twowheeldream |

anyone know if this is a 97 and earlier or a 98 and later oil pump problem? or has it happend to both? | ||

Reepicheep |

Mine was a 2000 Cyclone, and had the problem. | ||

Sportyeric |

'92 Sportster with about 85,000 miles showed wear identical to the pics in the first thread. Ready to go any time. Haven't looked at the pump yet. | ||

Whodom |

Still thinking about this problem, I dug out my machine design textbook ("Mechanical Engineering Design" 3rd edition, by J. E. Shigley). Gears of this type are called crossed-helical gears. Shigley has a couple of comments of interest: "Cross-helical, or spiral, gears are those in which the shaft centerlines are neither parallel nor intersecting. They are essentially non-enveloping worm gears, because the gear blanks have a cylindrical form... The teeth of crossed-helical gears have "point contact" with each other, which changes to "line contact" as the gears wear in. For this reason they will carry only very small loads. Crossed-helical gears are for instrumental applications, and they are definitely not recommended for use in the transmission of power." I also found this text on-line with info on crossed-helical gears: http://www.bostongear.com/pdf/gearology/chapter03.pdf It makes the point that lubrication is VERY important to the life of these gears. Not a lot here to help us diagnose what's causing these gears to wear in our Buells, but maybe this will lead to some further info with some searching. I think Al is correct that the problem can't be caused by the driven (oil pump) gear, because that would result in two evenly spaced wear locations on the drive gear and we're only seeing one. One thing that occurs to me however, if the drive gear is machined off-center, it seems like the gear would wear to a point where it fit properly and no further. If mis-meshing caused the problems on Al's S-1 (which had a gear worn to virtual knife points when he found it), it seems like the gears would have been so tight when he first cranked the bike that something would have broken much earlier. That leads me to believe that the root cause is non-uniform hardening of the drive gear. One other far-fetched possibility that occurred to me is if there is some way that the oil pump load is non-uniform. Can anyone think of a way this could occur? Maybe the scavenging section of the pump sees "slugs" of oil as the engine reciprocates? This would cause the gears to see a much higher load during part of their rotation which might explain the wear pattern. Just a thought. The other question is whether people who have replaced the drive gear still see the same wear pattern with their new gears. If not, this might at least show that the problem was a "bad batch" of gears that went into these engines and that replacing them will permanently (or at least semi-permanently) cure the problem. | ||

Kdkerr2 |

According to Whodom's insightful research on crossed helical gears Buell is using the correct application for the driving of an oil pump [according to my interpretation] since it's merely pumping oil not transferring power [such as the crankshaft]. Obviously the best way to power an oil pump would be to design a proprietary shaft coming off the pinion shaft to power the pump but this would make the system overly complex and add too many extra parts. Harley's original design is simple and does the job for the most part. I think this is a metalurgical problem, most likely improper heat treating of the gears or defective alloy in the gear itself. Has anyone had these worn gears Rockwell hardness tested? KK | ||

Whodom |

Kdkerr2, Whitebuell mentions that he had his new drive gear tested and it was relatively "soft" so he had it hardened by a machine shop prior to installing it (see http://www.badweatherbikers.com/buell/messages/3842/14795.html). You're right about this being a proper application for crossed-helical gears; lots of auto engines use the same arrangement to drive the distributor and oil pump off a gear on the camshaft. | ||

Al_lighton |

We took the oil pump out of Reindog's 2000 S3 yesterday. It has about the same mileage as my S3, around 27,000 miles. His gears were in about the same condition as mine, though the worn edges on his were a little sharper than mine. Plenty of tooth left still, so we just buttoned it back up the way it was. My 99 S3 has the same basic pump/flywheel/cams as my 98 S1W. In 2000, HD/Buell switched to the newer high contact ratio cam gears (finer pitch), changed the flywheel assembly method, lightened the flywheel, and changed the drive key from a funky looking key with an overhanging pinion drive tang to a longer square key. But the engagement of the pump to the drive gear didn't seem to change at all in 2000. Everyone should check there gears every 20,000 miles. It is really pretty easy. You only need to disconnect the front oil line from the pump. The two rear ones that go to the oil tank can be left connected. You need to disconnect the front shock eye and pivot the shock down, which means picking your bike up by something other than the swingarm. And you should really have the oil tank drained prior to doing it to minimize the mess, so it is best done at an oil change. One concern: I've pulled three pumps now. Every one of them had the two long 1/4-20 retaining bolts fight on the way out. That is, once torque was broken on the threads, they didn't spin freely, they got tougher. The threads were dry and galling on the way out, and I feared total thread destruction the entire time I was removing both bolts. I cleaned the threads with a tap and put antisieze on them for reinstallation. But the way they felt, surely someone is going to pull their bolt out with most of the aluminum threads still on the bolt. Al | ||

Reepicheep |

Great idea for the hardening thing... can you replace just the gear on the oil pump? Whatsit cost? That is a lot easier to get at, so even if hardening just makes the pump side wear instead of the crank side, it would be far easier to "service" every 15k miles or so. | ||

Kdkerr2 |

More study into this matter is needed. Hardening the oil pump drive gear may be overkill and just cause a premature wearing out of the oil pump gear. I have a son who is a metalurgist and his company does do case hardening but I don't know what the cost is. The hardness of both the drive gear and the oil pump gear needs to be determined. KK | ||

Whodom |

KK- I think you're right; the correct thing to do would be to determine the hardness of both gears. I wonder how Whitebuell's bike is holding up since he installed the hardened gear? His post was from July 2004 so he should be able to tell us how it's working out. I know that in automotive applications, they will sometimes (usually?) make the driven gear out of bronze so that it wears out rather than the driving gear which is an integral part of the (expensive) camshaft. Judging from the illustration in the parts book, the Buell oil pump shaft and gear are one piece (they only have one part number) which means you'd have to dismantle the oil pump to replace it but that still would be easier than replacing the driving gear. | ||

Whitebuell |

I have only hardened the drive gear,the oilpump gear is hard enough,the bike now has about 8000 miles,the drive gear is still in perfect shape . Normally it would be worn out by now,at least that's what happened to the the 2 drive gears i replaced before my modification. | ||

Whodom |

Whitebuell, Thanks for the update. Now of course, the question is what made the difference? The hardened drive gear, the modified oil pump which put the driven gear in the correct position, or a combination of the two? | ||

Mikej |

Sometimes I wonder what would happen if a thread like this was forwarded to the Harley-Davidson engine design team people showing them that some folks are re-engineering their design to solve problems encountered by end users. "It's a wonderful day in the neighborhood." | ||

Whodom |

Mike, I made a post under "for the factory" about this thread. It would be nice if someone from Buell read it and responded. | ||

Reepicheep |

I would not expect them to respond, this forum is not the place. I don't know, and would not tell without a court order even if I did know, but would expect they absolutely have read and are aware of the issues. We still don't have any good data if the problem is fixed with the XB platform, but I bet it is. I am over 5k on my 9sx already, I'm doing my part to gather data  | ||

Whodom |

Reepi, you're probably right that they wouldn't respond here. I might have better luck if I wrote a nice letter to customer service. Glad to see you're doing your part. I wonder if any of the XB riders have pulled their oil pumps to check- don't we have a few with 30k+ miles? | ||

Buellistic |

BUELLers: There is another thread about the oil pump drive gear failures on this board ... "i" read through these and it looks like any BUELL with a -98(-91A for sportsters)oil pump in the BUELL models from 1998 on have this trouble ... Whitebuell made a very good point about gear alignment which should be checked !!! There have been no screens in any BIG TWIN or Sportster/BUELL engines since 1976, "i" believe ... Everyone should know when H-D engines make "H-P" they also make metal in the oil ... "AND" everyone runs the BUELLschitte out of their BUELL weather it be a TUBE FRAME or an XB ... Only know two sporster riders that run there sportsters the way we do our BUELLs ... The -98(-91A sporster) oil pump was up-dated to suck oil out of the cam gear area and there in "i" believe where the problem is ... The return side of the oil pump pumps oil to the oil tank with metal in it and is getting a added dose of metal from the cam gear area which returns through the feed side of the oil pump which causes more drag on the oil pump than the pinion drive gear can stand ... "i" also think the engines are not being warmed up enough before being run hard !!! Have not heard as of yet of any XB or BLAST oil pump failures, so this may have been corrected ... Not eveyone will do what "i" have done which is to put a oil filter in the oil return line to the oil tank ... ie: metal in the oil only goes through the return side of the oil pump which 50% drag reduction !!! In BUELLing LaFayette | ||

Al_lighton |

The XB uses the same drive gear as XL/Blast/Sportsters do. Much of the XB 26357-02A pump internals are the same as the XL/Tuber 26204-91A pump. The Blast uses the XL 26204-91A pump, as do 05 sportsters. The assy number is different on the XB pumps, but I think it has more to do with the external fittings (rigid line instead of nipple) than the internal pump mechanics. It would be interesting to see if the pump elevation relative to the drive gear is the same on the newer bikes. Anyone have a photo of an XB cam chest from the side, or happen to have their cam chest open at the moment? It was pretty obvious to the naked eye that the gear wasn't at the same elevation on the XL cam chest, but is it intentional or is it a mistake? Seems unlikely that HD could make that many sportsters with an error like that, there must be a very good reason for it. I've added the parts for checking and repairing the problem to the web store. See oil pump drive gear | ||

Whitebuell |

i have put the drive gear in a centert place with the pump wheel because i believe those gears should turn centert and not of center . The above side of the oilpump gear has an scharp side and that side always cuts in the drive gear,witch gives the metal pieces(i think) When you look in to a gear box..;all the gears are te same hardness,so my logic was to make the oilpmump gears both the same hardness,since the pumpgear is much harder then the drive gear,i case hardend the drive gear. I also think that the hydraulic motion of the oil togheter with the georotor working of the pump creates the wear patern in the drive gear. Sportsters don't have the wear patern because most drivers don't hit the high rpm's like buellers do,that's also a reason for the wear of the gears in buell's. When you drive the buell like a sportster (slow and easy)then i don't think you are going to have some gear wearing out.I am thinking of putting some redshifts in the bike this winter and when i do ,i will make some pictures of the gear as it is now to prove that my modification really works. Also bee thinking of a pro-flow pump but i am not so sure that this pump really makes more psi then the buell pump,any toughts on this one? I have those squirters home made with XB pressure reliefs in it,pump delivers hot something like 13 psi,i know the xb's don't deliver any more but to be on the save side ... |