| Author | Message | ||

Bluzm2 |

Sorry Mike, None with the pulley off. Hmmm, wait a sec, I may have some pics from when my 5th gear needles went out this spring. They are on my computer at home, not here at work. I'll post them this evening.. Brad | ||

Todd_martin |

X1, Cyclone, Xb transmission I read that the case has to be split to rebuild the transmission on the Xb. Is this different than the other bikes? | ||

Reepicheep |

All the tubers have cartridge trannies that can be easily removed after pulling the primary cover. Nice. The XB's you have to split the cases. But they also get another rail or something, so they shift better. Most other motorcycles are the same, split the cases to work on the tranny. So far, based on the experiences of the people here, the Tubers have an easily removable tranny, and many people have to remove it. The XB's have a hard to remove transmission, and few people have to remove it. So while in theory I think the cassette tranny is a loss, in practice I don't know if it is a huge deal unless you are racing. (Message edited by reepicheep on September 22, 2004) | ||

Steveford |

My 02 X1 just had the shift detente plate's retention clip come adrift which didn't help the shifting much. The original detente plate ended up getting rather chewed up so when I went to put in a new plate and clip, I found that the plate wobbled to such an extent that it wouldn't contact the roller when fifth gear came around. The problem was that one of the shift drum's pins had worked it's way out of the drum and wasnt letting the detente plate sit square. Imagine, something vibrating it's way to freedom on a Buell! I don't believe that the pre-'04 Sportsters have this problem due to the rigid engine mounting? After driving the shift drum pin back in and with a lot of brake cleaner and some green Loctite on the pins, I'm hoping that the problem is cured on this bike. I'm aware of the Banke fix but only had access to the stock parts last night. Could the pins working their way out be what's causing other detente plate clips to abandon ship? | ||

Captainkirk |

Whoa...Deja Vu! I posted on exactly this same scenario back in June! I ended up doing the following; 1) Applied LocTite to the drum pin and drove it back in with a punch 2) Replaced the detent plate and clip. Be careful-the clips are nasty little buggers and questionable at best 3) No recurring problems...knock on wood! 4) Check your primary shoe-if you don't have the new one in, change it now. It's only about fifteen bucks or so. | ||

Jpc |

Reassembly is complete and a 50 mile test ride without any blood shed! The maingear needle bearings were slopped with moly assembly lube prior to insertion of the cartridge and the nasty noises seem to have been banished. Looking over the leftover parts, I think that the maingear was trashed from the original failure of the ball bearing - the heat discoloration is not uniform, and there is a corresponding worn area where the outboard needle bearing sat. So I should have replaced the maingear and the mainshaft the first time. All told, the replacement of the whole mainshaft train set me back about $600 including shop labor to rebuild the cartridge. There were some other costs for tools - 250 ft/lb torque wrench and large capacity retaining ring pliers account for most of that - and who knows how much time. Much of the time was spent head scratching, fabricating the maingear puller, or making parts/tools runs, for which a second bike would have been optimal. With all of the tools in place and a clearer understanding of how it's done, I could probably have a tranny out in about two hours now. But I'm glad I won't have to for at least another five years... | ||

Reepicheep |

Congrats! Good work! | ||

S3thunder |

My S3 is jumping out of first gear especially when first starting off in the morning. It jumps out and then slams back into gear. I was recently told by a local mechanic that this usually indicates a bent shifter fork. The guy that had this S3 before me loved to do wheelies. The bike has 53,400 miles on it and otherwise runs great. Is sooner better than later to pull this trans. How can I tell the year of a trans when it is out of the motorcycle? I can get a new trans of unknown year and application. I have done some mechanical on this bike but not sure I have the tools for this job. Thanks. | ||

Reepicheep |

The shift forks are pretty massive on your tranny, I doubt they are bent. It is probably worn dogs, so you will replace the problematic gear pair (sounds like first for your bike, it was 2nd on mine). Also note that tire hop can feel this way. It was worst on my D220's. Felt *just* like the worn dogs. Only happened at peak power, right around redline, in first gear. | ||

S3thunder |

Thanks for the reply Reepicheep, One more question? I am also hearing a very high pitched whining noise when I am taking off in 1st gear. Is this an indication I should plan on replacing the clutch pack at the same time as the tranny? I appreciate your help. BTW I am running D220s and I rarely ever redline in 1st, but do hit the rev limiter on occasion in 2nd or 3rd without the hopping problem. | ||

Captainkirk |

S3; That was also the first sign of my primary woes...but it turned out to be the shift plate; the attach clip was cracked, allowed the plate to "wobble", the drum pin to back out, etc, etc. Like Reep says, the shift forks are pretty hefty. Doubt the whining is your clutch; you'd have other symptoms, such as slipping clutch. Sounds more like a primary chain issue. Sounds like you need to pull the primary cover and check things out. You'll need to do this anyway to get to the tranny, so might as well roll up your sleeves and get going. Step #1 is to buy the shop manual if you don't already have it! | ||

Reepicheep |

I agree with Captiankirk, the clutches on these things are pretty bulletproof, I doubt that is your problem. Do you have the upgraded primary chain tensioner part? The backplate could be split, and that could be causing the primary chain to drag on the inside of your primary. It will look like you can set the right tension, but it won't be right. That would cause the whine, but not the jumping. The whine could also be from the 5th gear drive assembly. Does it ever jump twice? Or is it ALWAYS only once? Twice or more says wheel hop. Once says worn dogs. It could be that little plate as well, but my first guess would be worn dogs on the gears. It is not a bad job at all to have the transmission out on your bench for a detailed inspection. | ||

Captainkirk |

...unless you own a CityX which doesn't have a "cassette tranny"! (Sorry, Reep, couldn't resist that one)LOL  | ||

S3thunder |

HELP I need to know how to lubricate the mainshaft ie what grease that goes into the needle bearings on the output shaft? Also, am I crazy to put a new trans in without changing 5th gear if there is some shoulder wear on the 5th gear dogs? I've never had a problem with jumping out of 5th but have with 1st and 1st dogs are worn too. I'd like to get it back together this weekend. Thanks | ||

S3thunder |

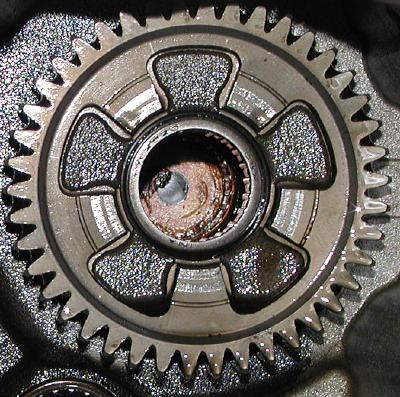

Here are some pics that show areas of concern. The wear on 1st looks only a little more than the wear on the 5th gear. The output needles look good and have been packed in grease of some kind and I wonder how they get lubricated.     | ||

Reepicheep |

Even when not packed in grease, I wonder how they get lubricated  Smarter people then I will no doubt chime in, but I don't know that packing them with a high quality grease is that bad an idea all said and done. Mine rusted to dust without it, and I *never* had my primary low on oil. | ||

Peter |

I always smother that bearing with assembly lube. Every now and then I pop the plug out of the shaft and have a check. Oil has never washed it out.... I had the gear set out a few days ago. The assembly lube had worked just fine keeping it "oiled" for a year. | ||

Hoser |

Hey Reap ....... The rust / failure was from water contamination , anyone who has drained their primary , discovering it's full of lubricant looking very much like Baily's Irish cream , could potentially be facing the same needle bearing failure scenario you experienced a while back .Extended riding in the rain should be followed by a primary oil change , water enters thru the clutch cable , condensation forms too, good maintenance and care can lessen the chance of problems. How do these bearings get lubricated ?? , not very well . Do use some grease when reassembling , don't use too much , you could push the small seal out of the end of fifth gear when the trans is installed. | ||

S3thunder |

Thank you to all who have responded with help and tips. I finished installing my trans @ noon 110704 and took it for a short ride. It works so fine. I am a bit perturbed by the manual instructions to remove the pulley on the output, there was no reason to do that unless I took out the fifth gear assembly. I put Mobil 1 75w-90 in the trans after using Sportrans most of its life and it is shifting better than ever, could be the new trans though. I am just back from a good shakedown ride on my favorite backyard roads and it is all good and sweet so far.  | ||

Captainkirk |

S3- great news! Hope it works well for ya! | ||

Nthielman |

Recently, I ran into a shifting problem with my 03 XB9S. Coming to a stop, I was unable to downshift (or upshift) at all. Luckily I was able to creep myself home, but the transmission appears to be stuck in 3rd or 4th gear. I pulled off the access plate above the shifter shaft to see if I could identify anything obvious...no luck of course. So I'm curious if anyone has ran into a similar situation and to see what was the problem. I consider myself mechanically-inclined and I'm tempted to pull the cover off to diagnose the problem, but I'm not sure if taking the bike to the dealer is a better option. Any ideas would be greatly appreciated. If anyone has an electronic copy of the service manual they could forward to me, that'd be awesome. | ||

Reepicheep |

It would not be a huge deal to get the primary cover off, and pull the clutch and stator assembly as a unit. Harder then an oil change, but not rocket science, especially on an XB. You will probably need a new primary cover gasket, anybody know if the XB uses the new metal type, or if they are paper? You can get the gaskets when you go to the dealer to buy the service manual, which is well worth the money. | ||

Buellistic |

Reepicheep: "FYI" the latest and greatest primary gasket for tube frame engine is so good it can reused two more times after first installation ... One the forth time the gasket will start to weep ... The "XB" gasket should be of the same quality !!! In BUELLing LaFayette | ||

Buellistic |

BUELLers: BTW if you have the transmission out the CLUTCH PRODUCT IMPROVEMENT should be done !!! Replace the SPRING PLATE PN 37977-90 with one FRICTION PLATE PN 37911-90 and two STEEL PLATEs PN 37913-90 ... This SPRING PLATE only lasts 50K to 70K miles ... "XB" and "BLAST" clutches DO NOT have this SPRING PLATE ... In BUELLing LaFayette | ||

Loki |

Must read this entire section now. Seems the S1(and myself) have destroyed the output shaft bearing. It now jiggles just like jello. Recent failure since the new top end went on the bike. Seeking advice, home brew tooling, mis-steps learned from, etc. Attempting to minimize downtime, as riding season is in full swing. Thanks to all. | ||

Buellistic |

Loki: "FYI" the rear DRIVE BELT(or chain) should have 2 inches of play on the tight spot ... Primary chain should be adjusted to 5/8" to 3/4" on the tight spot ... If you want me to e-mail you a INFO SHEET on this ping me(Ljenne73c@verizon.net) so "i" can get you e-mail address ... In BUELLing LaFayette | ||

Loki |

pinged ya. Can't say I did not cause this failure. I know I caught the belt being to tight a couple times. But after 22k of abusive miles I think the bearing wanted to be changed out. I noticed the other week that my swingarm shock tower was coated with oil. Also that the right side case was coated also. kinda thought it was a leaking cam cover gasket. Closer inspection said oil was not dark enuff to be coming from the engine side of things. As long as the main shaft is not damaged.....It should be a fairly quick repair. Gives me more of a reason to look at other things. like what a certian dealership did prior to my obtaining this bike. Never did like them or trust them. Same one that told me after three weeks my battery was toast on my M2. Three weeks to get a battery replaced under warranty. | ||

Reepicheep |

It's all doable, with a couple scary steps. You will probably need a shop (or hydraulic press) to press the needle bearings out of the 5th gear drive assembly, but you can probably get the assembly out yourself with some home built "tools" with parts from your local hardware store. I can offer the ones I built, but shipping would probably cost more then the components are worth, and it is very easy to build. I'll ship it if you want it though. I posted quite a bit about pulling mine from my cyclone in the knowledge vault. | ||

Loki |

Reep, Been doing the reading bit, the manual and the kv. Looks like a sane enuff task for me to accomplish. B-istic, got the mails. nice touch with the double filter set-up. | ||

Torqd |

I juts had my tranny lock up yesterday... pretty much welded the needle bearing to the main shaft... go the tranny pulled from the gear... the outer most bearing was oil-less... the inner most was like new... I still wonder how those things get oil or if they ever do... there is no hole in the shaft to lube way out there... Anyway... I am glad I had the bike out... only second time this year... I was going to make sure the battery was charged up and ready to go... because I was taking it to the dragstrip Sat... sliding to a stop at 40 is no big deal... kinda like my flat track bike... but sliding the rear at 130... I might not have made it :-( And as far as the clutches... I have 14000 miles on my bone stock clutch... the bike has had no less than 100rwhp since 1000 miles... and has had over 130 rwhp for a few thousand of those miles... still going strong... I think it is a special stock clutch... magical powers or something... my friend has some of the same engine mods and he has went through 3 diff clutches... including a barnett... Who knows... Anyone care to chime in on how that bearing is to get oil? |