| Author | Message | ||

Blake |

Neil: I haven't figured that one out yet. I just know that after an hour or so, I'm doing the side shift single cheek lean to work the blood back into vital parts.  | ||

Ccryder |

Hey, between my heated grips and my Gerbings jacket liner, this Buelligan is set! I plan on riding tomorrow just to show the nay-sayers what a Buelligan is ALL ABOUT  Blake, there must be some relationship that can be derived! I hear ya on the side saddle, my hips get sore, guess I'm just not exercising those joints enough. Any recommendations on an exercise? Anyway, the best seat pad to keep things flowing is the AirHawk (unfortunately their site is down right now) followed by the ProPad. Now I'll just have to see how this Corbin works out. Jim after a couple of trys with your Corbin what do you think? Time4Sleep. Neil S. | ||

Loki |

Here is one to consider..... Oregon Air, the people who brought you some mighty comfortable aircraft seats. The mil types and private pilots may be familar with thier products. Well they will also do custom cycle seats from the same materials. Not sure about pricing at this time. If they come even close to thier aircraft line it would be worth the money spent. My kiester has been planted in one of the seats many a day. Kinda make a ride in a C-130, MH-53, or a MH-60 more enjoyable. Loki | ||

Lake_Bueller |

Quick question...Are the seats for the S3 and M2 the same? I thought the rear section on both bikes was identical. Mennis | ||

Jiml |

Neil, It didn't seem to take that long getting the corbin to conform for comfort. But alas the S3 is gone from the stable now. Just keep getting the rides in and it will come to you. Lake_Bueller, The seats for the M2 and S3 are very different. So is the tail section body work. later, jiml | ||

H_Man |

Hey Loki, Do ya think Oregon Air will sell explosive bolts and an ejection system with their seats??? If I've got to do a get off at some point, may as well do it with STYLE. Your pal, H-man | ||

Loki |

H, I think the ACES-II might be a bit on the bulky side. Also one might be obligated to not using any tunnels. Just think about if you forgot to pin the thing while you go in for lunch. Some lurker comes by and POW your seat gets launched. Loki | ||

H_Man |

Loki, I s'pose you're right. It might be a bit awkward for cornering. BUT..., it'd be a pretty cool theft deterent. Sort of like James Bond's Austin Martin in "Goldfinger" :o} H. | ||

H_Man |

Oh yeah! HAPPY New Year, bro. H-man | ||

Anakie |

I have recently fitted a Corbin 'Gunfighter & Lady Seat' to my 99 M2 and the thumbscrew keeps coming loose over 10 mile trips to work. Has anyone had this problem? | ||

Kyuss |

I know this isn't P-3 territory, but no one is talking in our little section. I'm wondering if there is a taller fairing out there in production somewhere that will fit my blast. I would like a taller fairing now because I have the crossroads handlebars that are 6" more forward and 4 1/2" lower than the stock bars. wind is an issue now. | ||

Lake_Bueller |

Has anyone found carbon fiber mirrors and turn signals for an S3? I thought they would make a nice accent part. Mennis | ||

Buelliedan |

Kyuss, what about the factory Blast windshield? Would that work or are you trying to keep the sporty look? | ||

Kyuss |

I'm just trying something different AND sporty, but thanks Buelliedan | ||

Djkaplan |

Is anyone aware of a lower tubular handlebar (not clip-ons) that will work on M2's and X1's? The bend of the factory bars is quite odd; apparently to clear the tank. | ||

Blake |

DJ: Do you want to go lower and forward? How about a set of clipons with adjustable risers? Get more info on the bars below here (in the May 17, 2001 archives)  | ||

F16hd |

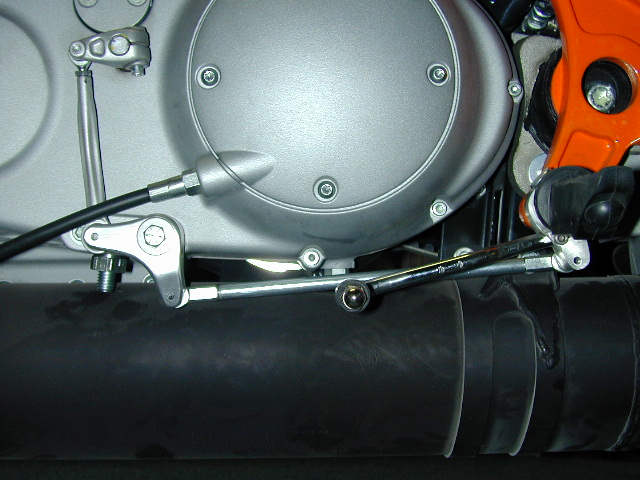

My first time posting (gonna try posting a pix too). After having been away from street bikes and road racing for many years, I could no longer resist the call of a new grey/orange '02 M2. After just a couple of hundred miles I realized that it was a wonderful bike...with perhaps the worst shifting I had ever experienced. Besides an ungainly axis of swing, all the fulcrum arms seemed to be very poorly concieved in angle and length. The only aftermarket stuff I saw was rearsets (these might cause my upper legs to crash with other "anatomy" parts). I didn't need rear setting, just better shifting. Since we commonly built our our (rearset) linkage in the old days (60-70s)I whipped up a new linkage set to improve my M2's shifting.... Works great!! The pedal tip is in exactly the same location as oem, but the total lever length is 1.5" longer than oem giving better leverage. In addition, the pedal now swings on the same axis as my ankle, and has a much more natural feel. I am interested to chat with anyone else that might have build a similar setup that has experimented with different intermediate fulcrum arm lengths. Harry in AZ | ||

Anakie |

Harry, I have a 99 M2 and I totally agree with you. Show us a piccie of your setup please! | ||

Aaron |

Harry's shifter pic:  | ||

Djkaplan |

Harry, Looks like you had lots of fun designing and fabbing that. Has anyone lowsided their 01-02 on the left side yet? I wonder how susceptible the new linkage is to damage? | ||

Reepicheep |

Excellent Harry! Nicely executed! I got the upgraded (2001) shifter, and while it is better, I am still unimpressed. It still seemed thrown together... though I don't think I have the update to it that gives it the best possible leverage. They also had some pretty strange torque specifications on the original documentation for it (or else I got badly confused) and I had to replace a small bolt I snapped, and I somehow managed to strip some of the length adjusting thread... but I digress. Anyway, excellent setup. Is this a one off setup with lots of machining, or are they normally available parts with just a little fabrication? Bill | ||

Ccryder |

Harry: Very nice! You had your thinking cap on for a few seconds to come up with that arrangement. It appears you have utilized some of the stock 01' components plus your own. Can I get it polished and in black anodized? Neil S. | ||

Bomber |

Harry . . .great work . . . . .with the decreased effort, is the length of the throws impacted by much? just what I needed, another idea to work out before Mid-March (tytpical return of regular riding season) | ||

F16hd |

First of all, THANK YOU Aaron for posting the photo for me. Thank y'all for the kind comments. Despite the appearance, everything is tucked nicely back and less vulnerable to lean angle than the stock parts. My current business is building race engines for pwcs (groupk.com), however we are hoping to make this linage setup for sale (it uses two stock linkage arms, and should fit all M2s and S2/3s. Unlikely I will get rich doing it.... but making nice stuff is it's own reward. If/When that happens, I'll post the info here. Thanks for the warm reception...I look forward to participating here. Harry in AZ | ||

Milehi |

Yo guys... Harry, I DO like that setup you built... I have a '97 S1 and it appears that the '01 upgrade won't work on my bike... Any ideas? Harry, wanna share your plans for your setup??? | ||

Ccryder |

Milehi: Just an FYI, the 2001 linkage will work on your S1. I am 90% sure it is the same one as the one for the X-1 (MRR which one did you use on your S1?)(maybe he will be listening). Neil S. | ||

Djkaplan |

Harry, The only disadvantage I can see with your linkage is that is makes centerstands that lift the bike by the peg mounts impossible to use. Congratulations; the reviews are good. Not ready to toss my '00 shifter just yet. | ||

Blake |

DJ: Prior to 2001, all the late model V-Twin Buells had the lever pivoting at the peg. I don't see how Harry's setup would necessarily hinder the use of a centerstand any more than the stock system. Harry: Nice thinking. You don't know how many times I've tried to think of a more elegant solution to the shifter system geometry. I'd be real interested in seeing a pic from an oblique angle, more up and forward so we can see the interface at the footpeg. Pretty nice work for a prototype! I have some free stress weenie advice. Wanna hear it? Here it is...  Though apparently made from stiffer/heavier steel versus the OE aluminum, the shifter lever seems a bit lacking in depth at it's root (at its pivot point). Something that might be easy to correct? Believe it or not, fatigue loading on the shift lever is a significant concern. Tensile stresses should be kept below the material's proportional limit (stress below which fatigue is not a factor) to avoid potential failures. Let's run a quick Mc/I bending stress calculation at the root of the lever... For every LB force applied to the shift lever we would have a bending moment (M) at the root of the 7.5IN long lever equal to... M=F*d = 1LB*7.5IN = 7.5 IN-LB I assume 1/4IN dia steel rod so... I=pD4/64= 0.00019175 IN4 and "c" is simply half the diameter... c=D/2 = 1/8 IN = 0.125 IN So the bending stress for every LB force applied to the lever is... s=Mc/I = 7.5/8/0.00019175 = 4,889 PSI/LB of lever effort. So for 10 LBs of effort you would be at 48,890 PSI. The proportional limit of steel is gonna be somewhere around 20,000 PSI. You can see why the factory aluminum levers are a tapered section with over an inch of depth at the pivot point. What is a reasonable design load for the shift lever... 10 LBs? Sounds reasonable enough, maybe even a little light, especially for downshifting. The above also assumes a total lack of stress risers in the root area of the lever. That could be true or not. Blake (stressanalysisisanoldhobbyofmine)  | ||

Road_Thing |

My nose is bleeding... Blake must be figuring again!! r-t | ||

Rall |

Yes, The 2001 X-1 shifter will work on a S-1. I installed one last winter on my 96 S-1. I like the way it shifts much better.Mobil one trans fluid helps in the shifting department also. Mark |