| Author | Message | ||

Peter |

Jim, Better in what way? Are they rolled? | ||

57sporty |

Folks, I just bought a bolt kit from Carolina Fastners off Ebay. http://cgi.ebay.com/ebaymotors/ws/eBayISAPI.dll?ViewItem&item=2421161225&categor y=35572&rd=1 His email address is: carofast@bellsouth.net I think that is correct. If not ping me offline and I can get you more info. I paid 29.00 for my kit and it looks great with the new gloss black powder coating on the cam, sprocket, primary and rocker boxes. I hope this helps. His Ebay name is carofast. Steve Queen 1999 88" Sportster | ||

Vr1203 |

Peter, I just figured the factory threads would be done better. Also the anodize ,I think is applied after the machining and it strengthens the surface.I'll call them Monday and get the lowdown. | ||

Aesquire |

listen to the soft small voice.... Titanium...Titanium.......  (Large bicycle rider break alum. bolts.. Ti rules! ) | ||

Vr1203 |

Aesquire,Can you find Ti socket head caps in 1/4X20 and NC sizes? I won't be using any aluminum in any stressed areas, 7075-T6,is very strong (and they are lighter). | ||

Bbuell |

HELP Does anybody know a fix for worn out nut plate on back of Seat on 2000 M2. No help in service manual or parts manual; has anybody had to replace it. Is a new seat the only option? | ||

Aesquire |

Vr1203, quick google search... Mettec I havn't dealt with them, but they look like they have a clue. | ||

Vr1203 |

Aesquire,They(Mettec) do offer a Ti. 1/4X20 S.H. cap at $8 a pc. I e-mailed them to see if they can get aluminum. | ||

Boyle |

Does anybody know the procedure for the engine isolators, on how to set them up setup. Any info on an X1 would be great. | ||

Awgrimm |

I am trying to upgrade to the new-style chain tensioner, and after draining, etc, find that I can't get the clutch cover off the bike! Does anyone know what size torx the bolts that hold the cover on are? The closest I have is a torx-25, and it seemed a little loose (do they even make like torx-26, or whatever?) I would hate to round them out! Other than that, any suggestions on getting them off? I read how easy the tensioner replacement was, and I would hate to screw it up before I even really get started. Thanks- Brad | ||

Reepicheep |

I don't remember the size, but those torx bolts strip with a sideways glance. Your friendly local Harley botique has some nice chrome allen head bolts to replace them. When you pull them, remove them gradually going around the circle. If you pull off two completely without loosening the other two at the same time, the whole cover skews and binds. If worst comes to worst, if you have to drill off the heads, there should be a decent enough amount of shaft left once the cover is pulled that you can get at 'em with vice grips. (err... at least there was for me  ) ) | ||

Awprior |

If you end up stripping those guys, use a Dremel to cut a small slot in them, and try a flat tip driver. If that doesn't work, make the slot a little bigger, place the driver at an angle and tap on it with a hammer. That's how I got two of mine out after breaking an easy-out off in them. The threads are 1/4"-20. I got a couple of capscrews from Lowes and put them on instead. I believe they were 3/4", with a washer or two as a spacer to get the same length as the stock ones. If you can't find the right size, I'll measure mine when I get home. Alex | ||

Shooter |

T-27 torx from the factory...somebody has a sick sense of humor.My theory is there good for 1 on/ off cycle then toss em.A 1/4-20 x 1" in any flavor of head you prefer will work fine.By yourself a impact screwdriver, the kind you wack with a hammer.With a 1/2" by 3/8" adapter you can use on all your dangerous screws (i.e. brake rotor screws). My goal is a torx free world !!! | ||

Vr1203 |

I have a supplier for 7075 aluminum 1/4X20 socket head cap screws. Does the the new XB's use that size? Look at your primary, timing and rocker covers. Any other places that are not stressed. Remember aluminum weighs only 1/3rd of steel, and the 7075 alloy is very strong. If I can get enough people interested, I might have them made.I need to make 1000 of them to get the price right. | ||

Vr1203 |

Again, I have a supplier for 7075 aluminum 1/4X20 socket head cap screws. Does the the new XB's use that size? Look at your primary, timing and rocker covers. Any other places that are not stressed. Remember aluminum weighs only 1/3rd of steel, and the 7075 alloy is very strong. If I can get enough people interested, I might have them made.I need to make 1000 of them to get the price right. .All the Metric sport bikes have aluminum hardware available.Looking for an advantage? Save some weight | ||

Doncasto |

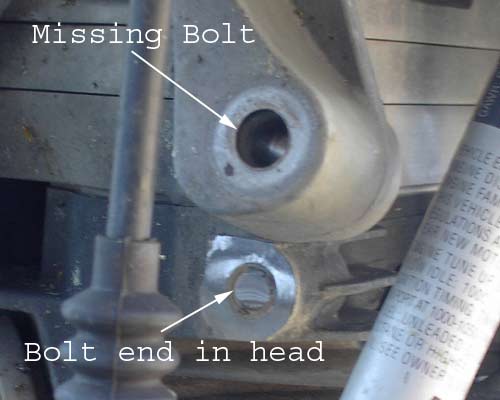

While riding back from a great trip to Ouray, Co Roz suddenly felt as though she was riding on a rumble strip. The above photo shows the reason. Questions for those that have already gone through this: 1) What are my options for removing the section of the bolt that remains in the head? Dremel tool slots and standard screw driver? Easy out? Machine shop? I'd appreciate a description of steps taken to remedy this. 2) Should I upgrade to grade 8 bolts or use just replace both bolts with stock (assuming grade 6 here)? 3) How many of you have had this problem? If I can get a show of hands with model, year and approximate mileage at failure I can determine if this syndrome should be included in my next "Conventional Wisdom" article. 5) Is this something that might be worth looking at as preventative maintenance at some number of miles? S3 Conventional Wisdom S2 Conventional Wisdom Thanks, Don Casto | ||

Doncasto |

I suspect this happened when I was going to get the replacement bolts yesterday. I seem to recall a "ping" when riding over a pavement transition (People's Republic of Boulder Roadway Improvement Project). Sort of makes the broken bolt inconsequential by comparison. Any ideas on how this might be fixed short of replacing the front head? Looks like my dog Charly and I will be spending lots of pedestrian time from now on . . . Bummed in Boulder, Don edited by doncasto on September 06, 2003 | ||

Steveshakeshaft |

Very interesting camera shot. You can clearly see that there is extra depth that the bolt could use. At the moment the weight of the engine is putting that lug in a bending/shear mode and clearly that is a bad idea, it's so weak that way. I think a bolt long enough to go deeper into that hole would help to strengthen the assembly considerably by putting the lug/head attachment into compression. I think I'll look carefully at this before I change the heads on my M2. Commiserations, you need a new front head IMO. Steve. | ||

Hans |

Hi Doncasto, When I first met Charley, not your dog, but our Dutch motor magician, he started just a project with an totaled X1. Seeing the broken off screw hole from the head, I supposed the head was worthless. I got only a light smile. On his old website he did show, later on, the pictures how he repaired the bike, and how he FIXED that screw hole, and made it as new. There is hope !! His new website is not finished and he has his holiday till Sept 14th, so I jumped in. http://bikehospital.nl his email: info@bikehospital.nl Goood luck, Hans | ||

Doncasto |

Hark! A glimmer of hope on an otherwise very cloudy horizon. Thanks, Hans! Steve: I now have the dissassembled enough to get a good look at the head. There is still about 3/8 inch of thread in the hole and it looks as though there is plenty of material for a deeper drill and tap. At this point I see the experiment as a nothing ventured/nothing gained/nothing to lose proposition. I was hoping the wall thickness where the bolt is attached might be enough for some sort of sleeve, but it looks as too thin. I will update as things sort themselves out. First impression (aside from the mess I made of the head/bracket connections) is how clean the inside of the rocker covers look. I lay responsibility for this squarely at the feet of Redline 20w50 full synthetic oil - which I have used for 36K of the engine's 38K miles. Thanks for any and all suggestions, tips, warnings and advice! Don edited by doncasto on September 06, 2003 | ||

Steveshakeshaft |

Don, Hmmm, food for thought. I can't fully recommend a repair, though the following comments might be useful. For a bolt threaded into a hole, to get the full strength of that connection (pulling the bolt in tension) you need about 1 1/2 times the diameter of the bolt as depth in the threaded hole. Now if you drill the threads from inside the broken bit so it is a close fitting sleeve over the bolt, deepen the hole in the head so it is at least 1 1/2 x the bolt diameter. Bolt the broken piece up nice and snug and weld it. The bolt is now holding deep in the head and not on the broken piece. The repaired piece is nice and snug under compression. You see where I'm coming from? I'm not saying do it. It's upto you. Steve. | ||

Doncasto |

Steve: We are thinking along the same lines. My working hypothesis is that if I drilled and tapped into the available material equal to and slightly more than the thread length in the broken tab, the fastening parameters should be about the same. Reattaching the broken part keeps the bracket configuration/lineup similar. Drilling out the unusable thread length and then welding should make the fix relatively permanent. A replacement bolt is the only remaining quandary. With conventional wisdom being that the OEM bolt is more technical than a grade 8, sourcing a longer version will take a little research. And if it doesn't work, I can now defer deflect all responsibility to you for making the suggestion . . . ;-{) Don edited by doncasto on September 07, 2003 | ||

Steveshakeshaft |

Errr, it don't work like that Don. You gotta read the disclaimers. But given that the head is on its second life, I'd be tempted to go with something really tough like a socket head allen bolt. IIRC, they are grade 12.6 (can't remember exactly?) as bought off the shelf. And I'd machine myself a nice thick washer. It's your neck, so you make the decision. Oh and BTW, who ever welds that piece on, I'd want to try and take a Dremel and make a weld prep once the two pieces are bolted firmly up together to get a pretty full penetration weld. It will be important to remember to remove the thread from inside that broken piece too. If you decide to do it, good luck and post us a pic of the repair. Steve. www.ukbeg.com steve_s@ukbeg.com | ||

Doncasto |

Thanks to everyone that helped with my recent sheared bolt episode! I have had Roz back on the road for about a month now and the gradually more comprehensive "road testing" has me believing my temporary repair will last until I can afford to replace the head. I'd appreciate hearing from anyone that has had these bolts break on the their Buells - either on currently owned bikes or previously owned. Thank you to those of you that have already responded! I have posted a report on the head bolt episode to:http://home.att.net/~castodon/boltreport.html FYI - I have also recently updated the Conventional Wisdom pages - of interest to most tube frame owners although specifically compiled for T'Bolt owners http://home.att.net/~castodon/DonCastosS2ConventionalWisdom.html http://home.att.net/~castodon/DonCastosS3ConventionalWisdom.html Thanks again to all that offered help, assistance and advice. Don edited by doncasto on December 02, 2003 | ||

Doncasto |

FYI - The people at Chromate were very helpful and critical to my recent repair. Check out their website at http://www.chromate.com Their fastener pages begin at http://www.chromate.com/Fasteners.htm The offer a complete line of fasteners as well as various shop supplies. If you can send them some business, please do. And be sure to say "Thanks" for me. Don | ||

Lake_bueller |

Question for the throbbing brain of the BWB.... Is there any reason I can't use titanium bolts in the motor mount if I can find that size? Or maybe even stainless? If stainless steel, what strength/grade? Thanks!!! | ||

Mikej |

If you are talking about the two big bolts that go thru the front mount/hanger into the front cylinder, then contact Don Casto for ordering info. If those are the bolt's you're talking about. | ||

Lake_bueller |

Anyone know the size of the upper bolt on the front isolator? I'm talking about the one that bolts through the isolator & frame. Thanks!! edited by lake_bueller on April 01, 2004 | ||

Reepicheep |

Hrrumph. Pulled the starter today to put in a new gasket to stop a slow leak that I have had since I got the bike, and everything was going great until I put the primary cover back on. I put the top two (longer) bolts in first, just finger snug to hold the primary in place while putting the rest on. Put the rest of the bolts on finger tight, then went back over them with the torque wrench at the sepecified range. When I got back to those top two bolts, they were stripped out. Never even tightened them. The cover must have been pivoting on something when I tightened the other bolts and it must have levered them right out. Who knows? Anyway, I now have to fix it. I am assuming a heli coil is the way to go. Are these self install deals, or professional install deals? Are they OK for steel bolts in aluminum cases? Where do you find them, or where do you find somebody to install them? Thanks! Bill | ||

Steveford |

HeliCoils are a piece of cake and you can get the kit you need at any auto parts store; I can't recall if you want 1/4-20 or 1/4-28 offhand. You carefully drill out the stripped hole, thread with the tap that's in the kit, thread in the HeliCoil with the mandrel, punch off the tang and then blow it out of the hole with compressed air and you're done. Be sure to go at least 1 full turn below the surface with the HeliCoil. The HeliCoil is stainless steel wire so anti seize or purple Loctite would be the way to go. |