| Author |

Message |

Jlnance

| | Posted on Thursday, April 20, 2006 - 09:15 pm: |

|

Hey Gramps! I don't know anyone at all with an S1. |

1313

| | Posted on Friday, April 21, 2006 - 02:19 am: |

|

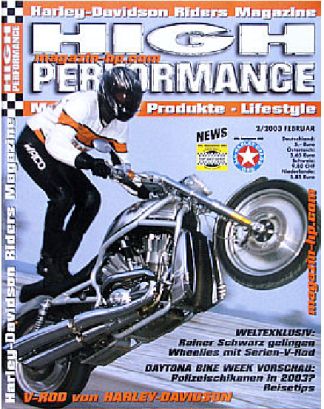

Yellow S1 with Blue wheels? That's not a factory combination for a S1 Lightning. But it did bring back memories of this beastly M2 put together in Buell R&D. The motor, astute viewers can tell, has been stroked. I can't remember who built the motor, but it was a well known H-D Sporty engine builder.

Sorry for the crappy photos (Dontcha just love the fact that old type film cameras are pretty much obsolete nowadays?), but you should see the crap I cut out of them...

Unfortunately the best motor shot is the worst picture...

1313 |

Jlnance

| | Posted on Friday, April 21, 2006 - 04:33 pm: |

|

Gramps, up for a ride in the morning? |

Jlnance

| | Posted on Friday, April 21, 2006 - 09:23 pm: |

|

Mark came over and we managed to remove 75% of my header studs.

I'm actually thrilled that we made progress. Of course the other 25% is going to be interesting.  We spent the rest of the evening calling everyone we could think of who might have that special drill guide for drilling out Harley studs. Brankin an Spike have messages from me on their phones. We spent the rest of the evening calling everyone we could think of who might have that special drill guide for drilling out Harley studs. Brankin an Spike have messages from me on their phones. |

1313

| | Posted on Friday, April 21, 2006 - 09:51 pm: |

|

Jim,

I heard the phone ringing as I was out in the garage myself, but I don't see any message on my phone. Not that it's important, though. The sad truth is that I don't have the tool you are in need of using. I think it would be a worthwhile resource for our group to collectively own, if nobody has one yet.

My project tonight was twofold. First I put the 28 tooth front sprocket kit on the V-Rod (bought the damn thing nearly 2 years ago), and second was removing the rear wheel in preparation for new rubber to be installed tomorrow (had the new rubber in my living room - right next to the 28 tooth front sprocket kit - for about 2 weeks now). After I get my new back tire put on tomorrow and get it back on the bike I will be headed (rain or shine) to Shelton's to get the speedo recalibrated. Lee @ Shelton's said that there is no cost for the speedo recalibration, while the New Bern village idiots, I mean Harley dealer Service Writer, assumed it would be about a half hours worth of labor. I was under the assumption that any download (even just for speedo recalibration) was 150 duckies. I sure hope Lee is right as it will definitely make me a happy camper and at the same time will make me kick myself in the arse for not doing it sooner. I want my V-Rod to scare the crap out of me again! It will be interesting to see what difference it makes on my own private dragstrip on the way to work Monday morning. Lately I've been pretty consistent at hitting 110 MPH before I have to slow it down to make the turn in to the parking lot safely. After I get used to the new gearing, I don't know what the next mod will be needed to keep it scaring the crap out of me...

So now that I've finally gotten the 28 tooth front sprocket kit on and fresh rubber, it seems as though I remember some drag racing challenge made by the owner of a certain Molten Orange M2...Unfortunately the Yellow XB9SL will most likely be in a different part of the country by the time we are ready to have a duel, but that doesn't mean we can't run off the V-Rod and the M2. Who knows, maybe others in our group might like to see just how well their scoots do on the dragstrip?

Anyone else think it was time for fresh rubber?

It was getting a little squirrely lately...

1313 |

M2nc

| | Posted on Friday, April 21, 2006 - 10:26 pm: |

|

Though the rear shock is not here yet, I too am going to go get fresh rubber on the M2 tomorrow. But the challenge was not for the M2, it was for one Yellow Nighthawk that is no longer in my stable. Oh well, the M2 will have to do.

I do need to at least replace that shaft seal, get a catch can on the vent tube, and put the rear shock on. Then I will be ready. Of course, I could always drag the Uly along, but I do not know if you would feel right running a dirt bike. |

Jlnance

| | Posted on Saturday, April 22, 2006 - 06:20 am: |

|

but I do not know if you would feel right running a dirt bike.

Race in the dirt.  But you can't ever come back here if he win. But you can't ever come back here if he win.  |

Sportymark

| | Posted on Saturday, April 22, 2006 - 08:53 am: |

|

Well last night was fun, and we (Jim bought them) have a set of Awesome Stud removers, just seems that the offending stud was a tad on the bent side to begin with so when the stud remover went to back it out....off it came. in our defense, the threads on both studs were FUBAR when we started, though it was a fun learning experience.

Hey 1313, is it possible to replace the front exhaust isolator on a blast with a solid piece? seems it would make more sense being it is solid mounted at the head.. |

Jlnance

| | Posted on Saturday, April 22, 2006 - 01:28 pm: |

|

Sometimes things go better than you expect them to, even if not perhaps like you envisioned. I went for a ride this morning, and stopped by Ray Price to see if Larry had the header stud drill guide we had spent last night looking for.

Larry had never heard of such a guide, but he did happen to be talking to another customer who was a machinest. The machinest told me to get something call a split point bit, and to start with a small hole, and work my way up through the bit sizes until I had the hole size I wanted. On my way home I stopped by Norther Hydrolics to get supplies. I found split point bits but it wasn't clear what they were intended for drilling. Next to there were some standard shape bits marked "Cobalt Steel - For drilling hard metals." I decided I'd rather have the cobalt bits. I wasn't sure this was all going to work, so I only bought a few bits along with a prick punch.

After I started drilling I realized I'd made the right choice. The cobalt bits cut through the steel stud like it was wood. It was amazing how easy it was to drill. The only difficult part was getting the drill around the cooling fins with the shorter bits. But in about 10 minutes I had a 1/8th inch hole drilled into my stud:

I called Mark with the news and to find out what size the ez-out required. Then I ran off to get the rest of the supplies.

1/4 inch is a big hole. The bits were great. It didn't take me long at all before I popped through the back of the stud.

|

Jlnance

| | Posted on Saturday, April 22, 2006 - 02:40 pm: |

|

What do you know, they are local.

|

Oldog

| | Posted on Saturday, April 22, 2006 - 04:59 pm: |

|

JL

as an Old machinest(sp) that was a good choice,

cobalt is the best and most expensive drill steel made..

Most brad point or split point tools are for softer materials and dont last too long on steel

If you have not removed the stud yet, and have not started with the EZout DONT!

ezouts are notorious for breaking in the holes then you have a mess

they are harder than the Devils teeth

I believe that the hole is 5/16 - 24, drill it up to tap drill size

If you hit it dead center,

and CAREFULY attempt to Tap the hole, a 2 flute tap is best, 4 flute taps should be used with the utmost care as they are prone to break and are as bad as an ez out with the exception that some times they can be broken with a punch and extracted in pieces where an ez out acts like a plug and tends to wedge its self into the work.

( don't ask how I know )

in the future, IF you can find one use a left hand drill bit, I am dead serious here

many times the broken off screw backs out once the LH drill bites in

Im glad that you had good luck with this so far, I have thought about it I need to find out what the hardened drill bushing sells for, a scrap of aluminum about 3 " x 5/15" will make the body, for a guide and an exhaust collar can be used to transfer the holes to the plate,

Sorry I digress..

one last thought here, If you missed center and get to the tips of the threads on one side try to pick the stud out it may come out as a portion

my first bike repair project decades ago was broken exhaust studs, good luck

I hope that this helps

Brankin:

looks like a prime canidate for the burnout pit..

you can almost see the air through those chords.

(Message edited by oldog on April 22, 2006) |

Oldog

| | Posted on Saturday, April 22, 2006 - 05:08 pm: |

|

Oh:

I forgot to mention I have a laptop and the VSDS software for testing and TPS zero / afv reset if any one ever needs help with it

I am not sure if it is compatible with the '06 bikes. |

Twig

| | Posted on Saturday, April 22, 2006 - 05:43 pm: |

|

Since I bought my xb a little over a year ago, I've only seen one other Buell riding around Greensboro. One of my coworkers recently moved, and the guy happens to live down the street from him. A yellow xb9s.I'll have to check it out. Should have my parts for the 06 belt upgrade in less than two weeks. Oh, most of you probably don't know, but my brand new belt (600 miles) crapped out on me. U4euh... you have another spare belt coming your way! |

M2nc

| | Posted on Saturday, April 22, 2006 - 06:35 pm: |

|

Twig - Sorry to hear about the belt. You know I met a guy that said he was the director of the Greensboro BRAG chapter at Michael's in Chapel Hill. I told him we were on Bad Web but I have never seen him on here.

JL - Keep up the good work and write ups. You have us all following you stud issue. I mean the one on the bike.

You really killed with that one!

Dave and I went to Ron Ayers today to have the new tire mounted on the rim and they had a used Ninja 250R there for a good price. I looked it over pretty good for a commuter bike service. After getting back to Dave's and mounting the wheel on the bike, we kick the numbers around and it just doesn't make sense for me to get another bike just for commuter service. The cost of entry, even at the $2000 would take eight years to pay off in gas. So to the reep the benefits now, I would have to sell the M2 to get a Blast or 250R. No, that is not going to happen. Oh well, I guess for now these two will have to do. |

Twig

| | Posted on Saturday, April 22, 2006 - 07:46 pm: |

|

M2nc... Would you be interested in a 1984 Honda VT500 Ascot, real low mileage? It only needs two weekends worth of work to be a damn fine daily commuter. I'll make a great deal.I would love to find it a good home. |

Jlnance

| | Posted on Saturday, April 22, 2006 - 08:45 pm: |

|

Olddog - Thanks for the tips! Of course I didn't read them till after we finished up  . We ended up doing about what you said, so it feels good to know we did it right. . We ended up doing about what you said, so it feels good to know we did it right.

Mark came over with the ez outs and it didn't look like it was going to be an easy job. I really didn't want to break the ez out off in there, so we decided to helicoil it. I'd never used one of those before, but Mark had. I drilled out the hole to the Helicoil size, put some of the cutting soluttion on the tap, and Mark cut the threads.

We screwed in the helicoil and wow, we had threads:

I'm excited. I'm just waiting on parts from DaveS now.

And big thanks to Sportymark. I'd still have 2 studs stuck in the head if I hadn't had his help. |

Sportymark

| | Posted on Saturday, April 22, 2006 - 09:20 pm: |

|

No problem, loved the work(better than shoveling Stone, or listening to ringtones) last time I removed broken stud and heli coied it it was on a Small block for head, in a mustang at the time, this was significantly easier... nothing in the way!...

once I got there and tried the easy out, I looked at it more clearly somebody had either crossthreaded the stud or it Galled really bad going in... it was solid in there. though the idea of the left handed bit is always a good one just finding them that is tough. I have some machinist catalogs somewhere, i shoudl get a set of them.

overall other than a pic of my bald head on Badweb i am good

(Message edited by sportymark on April 22, 2006) |

M2nc

| | Posted on Sunday, April 23, 2006 - 10:00 am: |

|

Twig - VT Ascots are just about iconic these days. I'm sure finding it a good home would not be a problem. If I am right, you can get about the same for the 1984 Ascot as a 2004 Blast or 2005 Ninja 250R. Either way, I am just going to get the M2 in shape and start sharing the mileage between it and the Uly for now.

I will be riding the M2 to work this week now that I have the new tire on. I have the grips in and the shock is on its way. I will have to bother Brankin for tools and guidance again to get the shaft seal replaced, then a K&N breather and catch can, and the bike is ready for another year. |

1313

| | Posted on Sunday, April 23, 2006 - 10:59 am: |

|

Carlos,

No problem on the guidance and (most of the) tools. We need to locate a torque wrench that will click in the reverse direction (at 80 ft lbs if memory serves me right) to ensure we're putting it back together completely right.

That's what I miss about so few tubers in the group - little chance for free food and beer.

Speaking of tubers. When I was partially soaked at Shelton's yesterday I sat and talked with John Martindale. Some bad news is that he sold his Buell XB9S. But the guy he sold it to has a S1 Lightning. John is considering paying the guys 1st year in National BRAG with the stipulation that he at least joins our group for some meetings/rides. Potentially another tuber!

Sportymark,

When Buell had all the exhaust problems with the later tubers (the header that went underneath the frame - '99-'02 models), we posed the same question 'Why not get rid of the bushings in the exhaust mounts and solid mount the exhaust?'. Erik advised us that the failures would even be worse with a solid mounted exhaust. I remember seeing a lot of Blast! exhausts coming back from the test facility and for every one there was a determination that something wasn't right when it was made (missing weld in certain area, etc.). I don't remember seeing many Blast! parts come back through warranty though so the exhaust issues were resolved before production. Brainfart! The reason for Jim's exhaust failure is that the header nuts were loose or had insufficient clamp load. The exhaust on ANY Buell is a very critical area to ensure that every fastener is tight. After fresh installation of the exhaust on my S2 after about a half a dozen heat cycles I go back and re-tighten all the exhaust fasteners, and may even need to do it after another dozen or so heat cycles. And most importantly before any sizeable trip, I make sure all exhaust fasteners are tight. Loosing clamp load (indirectly measured by the torque specification) on ANY fastener could have dire consequences on the life of the exhaust on your Buell. I must say the exhaust mounting on the XB's appears to be a much more robust solution, but I have no direct experience with it.

Oldog,

looks like a prime canidate for the burnout pit..

you can almost see the air through those chords.

I was trying to practice some burnouts with it, but even with a bald back tire it just pushes the front end forward. And with rolling burnouts - going about 25 MPH, pulling in the clutch, revving it up to about 5,000 RPM and dumping the clutch - did not produce the results expected, it actually kind of bogged itself down - maybe I shoulda tried higher RPM's as ther eis no way the front end is gonna come up unless I do what Craig Jones, Bubba Blackwell, or Rainer Schwarz do and stand on the seat.

Maybe what I heard was for the 28 tooth front sprocket gearing.

Also a small note on the exhaust studs. One side (nut side) is fine thread (5/16-24), while the portion in the head is coarse thread (5/16-18). It's hard to tell, but the beat up threads in Jim's picture (of just the exhaust studs) is fine thread where the nut would be and the undamged threads from the head side are coarse thread.

Good job Jim and Mark! Now I know who to call the next time I break an exhaust stud on my S2... Actually the last time I had a buddy out in Vacneboro that rides a 93 inch pan/shovel remove the remnants of the broken studs and the first time it was Buell's own R&D machinist. Actually the last time I had a buddy out in Vacneboro that rides a 93 inch pan/shovel remove the remnants of the broken studs and the first time it was Buell's own R&D machinist.

Racing is dirt?!?! Looks like I got the wrong tire for that kind of action...I think the raked triple clamps on the V-Rod would truly show the flopping tendencies of the old school choppers if I were to even attempt to go fast in dirt...

1313 |

Sportymark

| | Posted on Sunday, April 23, 2006 - 12:21 pm: |

|

yeah I attribite the beat up fine thread to when he mentioned he had the nuts work loose and the flange rattled on the threads for an amount of time flattening the tops of the threads. then when the nuts were torqued back on it just killed what was left.

No the course threadsin the head....they wer ein good shape on one(thoug it looked like they had used red locktite on it. th eother there was not enough left of it for me to get a good look at after we drilled it out |

Jlnance

| | Posted on Sunday, April 23, 2006 - 07:11 pm: |

|

264 miles today. Got back from Morrow Mtn with u4euh. We rode the C3 Jr route. It's goona be fun. Now it's naptime. |

M2nc

| | Posted on Sunday, April 23, 2006 - 08:30 pm: |

|

Put 30 miles on the M2. I got to admit it is the Uly's alter-ego. I was riding down a deserted back road, cracking the throttle through the gears as I break out of the wooded area, I pass a house with several people enjoying the late afternoon. They all sit up and turned around as I pass, down shifting for a 30mph turn in front of me. With the rear shock in its present state its a little like riding a pogo stick over dips, but it will do until the new shock gets here. |

Jlnance

| | Posted on Sunday, April 23, 2006 - 08:58 pm: |

|

Jim's Tire at the start of the day:

And again at the end:

|

Oldog

| | Posted on Sunday, April 23, 2006 - 09:33 pm: |

|

Were any of ya'll down this way, an XB lightning passed me I was looking at some property when he went by, on 117 south bound ~ 430 pm |

Ulywife

| | Posted on Sunday, April 23, 2006 - 11:32 pm: |

|

U4euh - Nice decal on your bike! Sounds like you two had a nice ride.

Carlos is done with finals this week and then he's off to IN to help Dave move. Another long trip for the Uly. |

1313

| | Posted on Sunday, April 23, 2006 - 11:41 pm: |

|

U4euh,

I'm proud of you! Do not let good rubber go by unused! What is the total mileage figure for those Continental Road Attacks? I'm seriously considering them the next time I need rubber for the S2 based on what I heard at March Badness 3.

I'm betting Carlos's Uly rear tire will look similar to yours by the time he gets back from Indiana.

1313 |

Ulywife

| | Posted on Monday, April 24, 2006 - 12:18 am: |

|

If Carlos makes me drive that trailer to pick him up on his way home from IN because of a tire situation (again), he's going to own me BIG! I haven't even collected on MB3 yet!

I guess I should go ahead and order a new set of tires for the Uly so they will be here when he gets back since it's only 2 weeks later that he and Carlee have their adventure.

I'm hoping that the shock comes in early this week, as Dave has offered to replace it for him since he has NO free time.

Mark also said that he and John could probably duplicate the device you have at home to stabilize the bike when the wheel is off. Sounds like time for pictures and measurements! |

Jlnance

| | Posted on Monday, April 24, 2006 - 06:34 am: |

|

Oldog - Not me. Looks like you've another potential friend if you can find him again. |

Jlnance

| | Posted on Monday, April 24, 2006 - 06:42 am: |

|

I have a laptop and the VSDS software for testing and TPS zero / afv reset

I think I may take you up on that. My bike surges a little, and I'm not convinced that it isn't due to the TPS not being zeroed properly. |

Jlnance

| | Posted on Monday, April 24, 2006 - 06:44 am: |

|

I haven't even collected on MB3 yet!

Are you sure you don't owe him for MB3?  |

|

C3 (Carolina Corner Carvers) »

Archives 001 »

Archive through April 24, 2006

C3 (Carolina Corner Carvers) »

Archives 001 »

Archive through April 24, 2006

C3 (Carolina Corner Carvers) »

Archives 001 »

Archive through April 24, 2006

C3 (Carolina Corner Carvers) »

Archives 001 »

Archive through April 24, 2006