| Author | Message | ||

Ochoa0042 |

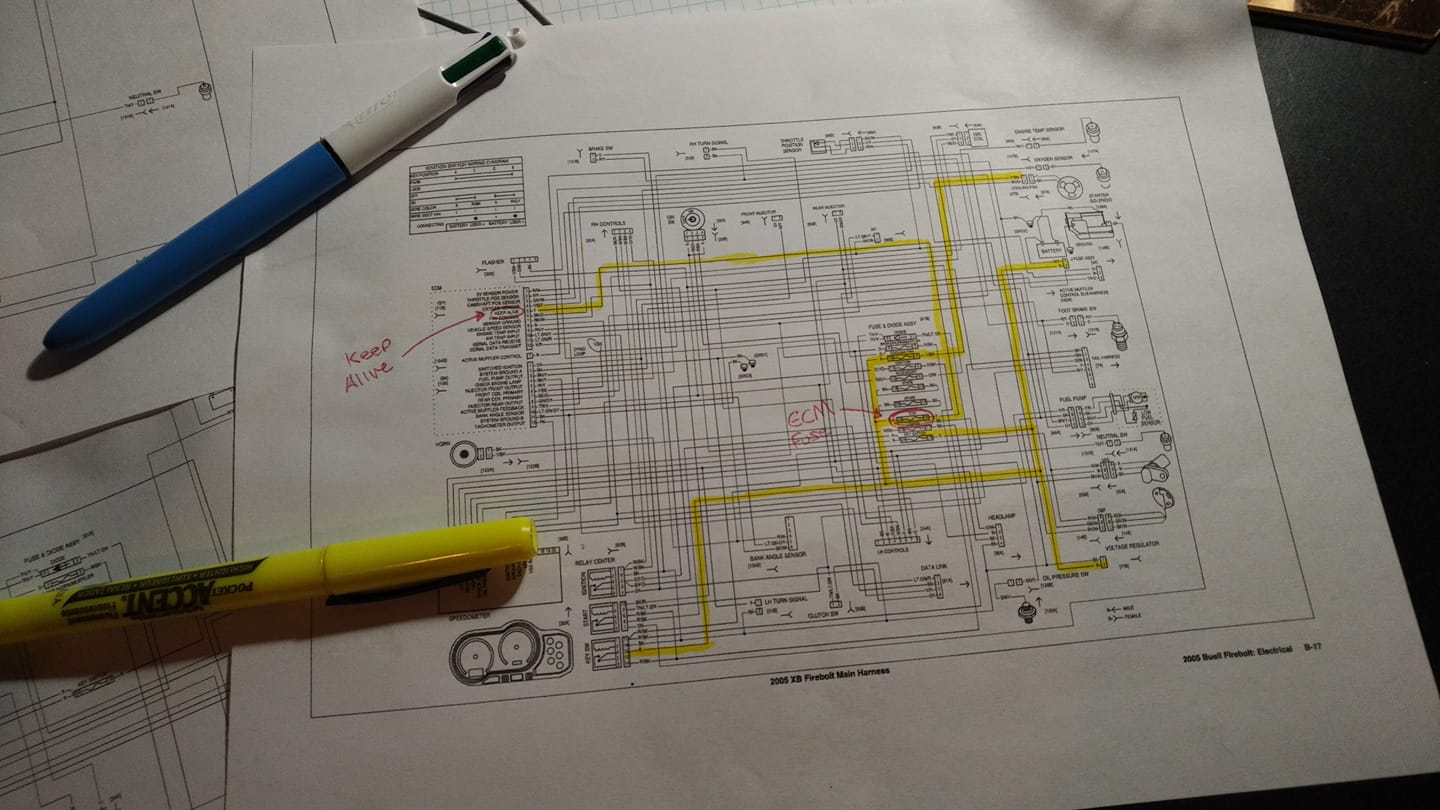

What is the "Keep Alive" function used for on an ECU? The ECU has both 12volt & 5volt in its circuits.. From what I've read, the Keep Alive is an INPUT. I'm looking for an OUTPUT signal (if any) that denotes the engine is running  | ||

Griffmeister |

From what it looks like thatís unswitched battery power to the ECU for memory. I donít think thereís anything outside the ECU that cares if the engine is running or not. Donít have my manual handy, need a bigger picture to tell for sure. | ||

Greg_e |

I'm fairly certain everything lights up when key and run switch are on, nothing that is run specific. | ||

Nik |

In other applications I have wired up an RPM switch set below idle to the tach output to create a discrete "engine on" output. | ||

Griffmeister |

For that matter, the oil pressure switch will only change state when the engine is running. That would give you a simpler yes or no signal rather than having to create a specific rpm trigger. | ||

Teeps |

Ochoa0042 Posted on Friday, August 31, 2018 I'm looking for an OUTPUT signal (if any) that denotes the engine is running What are you trying to do? | ||

Ochoa0042 |

Griffmeister, That might be a real simple approach to it and can work. Nik, How did you manage that? The circuitry that I'm working with has to be 5 Volts. Hopefully the Tachometer is 5 volts. If so, I can have the the device Tach input at an Analogue input and output back to the Tach as a PWM. Teeps, Trying to make a device that will start my engine. Once the engine is started, I need a failsafe signal to note the engine is on/running so that the device doesn't start the engine again by mistake of user/or/code input. All to prevent damaging the starter motor or primary. | ||

Shoggin |

About $25 on e-bay will get you an RFID secure system that will easily do that, and are actually pretty dependable too. They are easy to install on a bike and typically use a rpm input >400 to read engine 'on' status instead of oil pressure because cranking an engine can supply enough oil pressure to close the pressure switch. | ||

Teeps |

If I understand: you are looking for a circuit that, when the ignition is on, and the engine is NOT running has zero volts. and, when the engine IS running has 5V. I don't think the Buell DDFI 2 system has such an input. Sorry, I don't have any useful info for you Ochoa. | ||

Ochoa0042 |

Teeps, Correct. Having a 5 volt output would make it easier, yes.. but... All that the circuit would need to correct this is a voltage regulator / resistor / p-channel mosfet to lower the voltage. | ||

Teeps |

You're over my pay grade talking about p-channel mosfet. | ||

Shoggin |

The only difference in a 'running' or 'ignition-on/non-running' engine is the oil pressure switch ground/no ground or the RPM signal. This isn't Buell specific. It's damn near universal. That is why the circuit you are trying to build from scratch will: "typically use a rpm input >400 to read engine 'on' status instead of oil pressure because cranking an engine can supply enough oil pressure to close the pressure switch." | ||

Griffmeister |

Well, you could always use either a timer or a latching relay for a bare bones basic dumb circuit. Probably most important will be what is the smallest and most reliable. Interesting thought exercise though. |