| Author | Message | ||

Hogs |

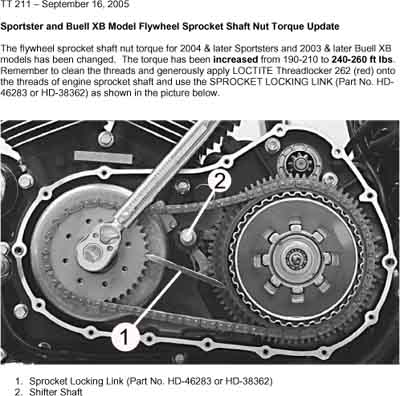

Hey Guys, Going to be changing the Front engine sprocket/Pulley and chain on a Xb12 for the xb9 units.... What tools wd. I need... I am thinking a Torque wrench that will do 250 lbs for the front sprocket..But not sure whats all involved for the Clutch basket to take that off??? ( Is there a special tool for this ) Also can one get by without any tool to remove the front Pulley Nut and reinstall so one can put the 250 lbs. of torque on it? Like a junk of Hard wood or a Rag/towel between the chain and sprocket? also to remove the Clutch basket... Hope this makes sense.... Anyone that has made their own tool s to do this wd. be appreciated... Thanks | ||

Andersonhdj |

Sprocket locking bar dimensions 3.875" long, 1" wide, .25" stock, deep angled end. | ||

Brother_in_buells |

Or one of this,  | ||

Djohnk |

I used the hinge mentioned above.. a chunk of hardware like you mentioned would probably work also | ||

Andersonhdj |

There are probably many things that would work, though chunks of wood and rags are generally recipies for disaster. It only takes about 10 minutes to fabricate the tool! | ||

Greg_e |

The brass hinge has the advantage of being softer than the gears so it should not allow damage to the gears if things slip. A big brass bar would also work if you happen to have one laying around. You could probably make a thick chunk of aluminum work a few times too. | ||

Hogs |

Thanks guys...Like to see what u all use...What about the Clutch basket? Some made tools up for this as well I forget?? Thanks | ||

Andersonhdj |

Do you mean to actually lock the clutch basket to loosen the nut? A dodge i'v pulled before on riceburners is to leave the clutch pack in place to provide a little binding and apply a pneumatic wrench. The trick is not to ram the wrench in but rather to sort of hold it so that it covers the nut without actually touching the basket. You sorta loose the plot a bit, once you touch the basket and while it might work ok, there a chance of damage to the basket itself. If you've got some old plates knocking about, take a steel plate and a fibre plate and carefully align the two to be concentric to one another, then drill and pop rivet in however many positions suits you, i found 3 usually does the job quite adequately. Put your freshly locked together plates in place, use the locking bar to lock the 2 sprockets and apply powerbar and socket and loosen your nut. | ||

Brother_in_buells |

Hogs ,you mean something like this!?   i like this idea ,so saved the pics. | ||

Greg_e |

What diameter is that PVC? | ||

Brother_in_buells |

,i found the pics on here ,you have to measure that on the clutch basket when you're working on it ,i found the pics on here ,you have to measure that on the clutch basket when you're working on it | ||

Hogs |

Interesting..I think there is a few other guys on here that had a DIY clutch basket tool to remove...anyone else have some thoughts/ ideals on this tool? Thanks |