| Author | Message | ||

Albert666 |

this vid was taken on a mount i made using the mudguard fixings | ||

Ericz |

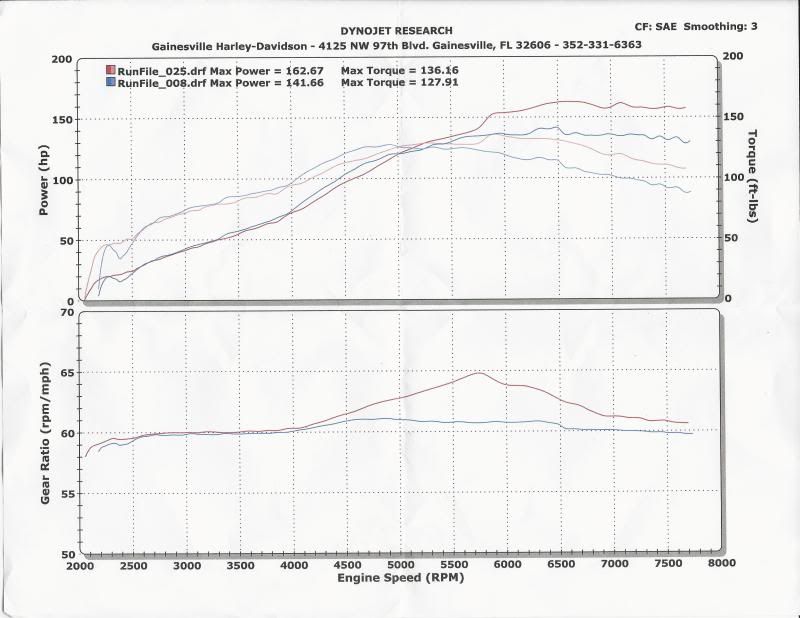

Looks like I need to find another solution to a clutch assembly. The Evolution Industries Stage 1 clutch does not hold more that ~130ft-lbs of torque. Here are two dyno runs that show it slipping as the torque increases to the 130ft-lb mark. The blue dyno run is running around 10psi and the red is running around 15psi. The clutch slips in both runs beginning around 4000rpm and continues until 6500 on the 10psi run and until redline on the 15psi run. I think I will go back with a XB basket and hub, Barnett carbon fiber plates, a Rivera-Primo Competition diaphragm spring and see what it will hold. That was my old setup and it held at least 150ft-lbs of torque. A lock up assembly may have to be added on top to provide the holding power I need.  | ||

Fast1075 |

I don't have much real experience with Buell/Harley clutches, but it is a fact on the bikes I do have experience with, the lockup is the way to go. I fear that if you put enough spring in it, it will fail the cover, or the cable, or be so damn hard to pull as to be unusable on a street bike. On my Kawi's with manual clutches, I could pull and hold the clutch with one finger. Once they got spun up, it would hold as much power as I wanted to feed them. The only disadvantage, if you will, is at WOT/max rpm, it was absolutely impossible to pull the clutch. So if you go lock up, I strongly recommend multiple redundant engine kill. That can be reached by either hand without taking you hand off the grip Not much is more horrifying than a throttle stuck in the traps at 175+ and you can't reach the only kill without risking a blow-off...DAMHIK. | ||

Ericz |

Fast, I have experienced only one lock up clutch before and I can't say that it felt more difficult to pull in at higher rpm, but it was hydraulic and not cable operated. I can see how it should be more difficult to operate. If it gets really difficult to pull in at higher rpm, how are you supposed to shift up? Just a clutchless shift? I would not want to have to do that all the time. I may have to compare the mechanical advantage of a stock cable and ball/ramp setup, a cable and Mueller ball/ramp setup, and a hydraulic conversion. I love the feel of the cable operated clutch but I just might have to use what ever has the best mechanical advantage. My primary cover has been strengthened around the clutch actuator lip. | ||

Fast1075 |

If you hang enough weight on a lock up, it will stay locked up until the clutch basket slows down enough for the centrifugal force to weaken. I have seen strong guys pull the end off a cable in panic. I always ran MTC lockups, either the 2 stage or the slider or slider hybrid. (the slider is a pure centrifugal, but can be modified for a hand launch..I frankly don't know if they ever built any Harley stuff. As far as shifting goes, I ran air shifters with electronic kill from a Schnitz Pro-ET or Pro Mod box depending on the state of the nitrous tune. I think I saw that you had R&D work the transmission, and it is filled with top end everything. In the import world, we mostly ran Orient Express stuff for 5 and six speed transmissions. Just sayin' I have ridden (or TRIED to ride) some Big Twin or Sportster powered bikes that I could just barely pull the lever, an on a couple, I couldn't pull it at all) Thats why my XB has a clutch lite and an 06+ spring. But then again mine don't make very much power. | ||

Blownharley |

http://www.mpsracing.com/products/MTC/GenIIClutch. asp http://www.banditmachineworks.com/sportster.htm http://www.aim-tamachi.com/home.php?cat=19 | ||

Ericz |

Ouch! almost $2000 for a MTC multistage unit and I'm sure the others are not much cheaper. I just emailed the guys at Evolution Industries to see what they have to say. I hope that I can end up with some combination that holds up where I don't have to modify the primary cover. I am considering a Magura hydraulic setup to make things a little easier. Hmmmm.... | ||

Blownharley |

I'm considering buying a Hayes convertible clutch to my 1125 but still think it's way to expensive! This clutch is $2250!!! http://www.haysmachineonline.com/buell-1125r-conve rtable-clutch/ Probably a nice clutch though.... Regarding the hydraulic clutch, its only eliminates the friction in the wire.. | ||

Greg_e |

Could you machine an inspection cover with a tube that runs down the center to reinforce the lips for the ramp? That might help spread some of the load out to that cover and three more bolts to hold it all. Not very much help, but every little bit adds a few more pounds of force for the springs. | ||

Xxxue |

Well you could always detune it or just put in a new clutch every 500 miles. | ||

H2opatrol |

Yeah but if he detunes it, you will make up a story and ramble on for years about how he failed and you saw it coming | ||

Ericz |

Haha! I think I have a clutch in the works that will hold up. Going back to a stock XB basket and hub, Energy One clutch pack and an AIM 480lb diaphragm spring. I'll see how that does and if I need more holding power, I'll modify the primary cover to fit an AIM Variable Pressure Clutch assembly. AIM claims that the combination of the 480lb spring and the additional 120lbs of force from the centrifugal assembly should hold around 190ft-lbs of torque. | ||

Ducxl |

I used Bandit machine works when my clutch basket began to fail.Mr. Mcgee is a smart man.I never got my clutch reliable.sold it to a sucker who could only see the 89 inches. | ||

Ducxl |

All I'm saying is,you end up endlessly chasing the weak link.this is the current one.next up is shearing the spine off the drive sprocket. A novice watching this might be misled. | ||

Xxxue |

You seem like you know what your doing and do good work, but the weak link in the chain is the overall design of harley engine. If you keep the boost down to where you only make around 115-125 hp the engine and tranny will probably hold up a lot longer. What your doing is like trying see to how far you can take it before it explodes. just hope it doesn't happen when your riding it. You should really get yourself a used hayabusa and drop a turbo into, its a proven design and there are a lot of aftermarket turbo and heavy duty engine parts available. | ||

Stevelknivel |

You trolls are missing the point. Yup, he will always be chasing the weak link until he gets it where he wants it to be. Just how it goes when you build something fast no matter what kind of vehicle it is. Where some people see problems, Eric sees opportunities to improve his machine. From an engineering perspective there is nothing inherently "wrong" with a HD motor/transmission, especially not one that's built from the ground up for the intended abuse. That's well proven in the drag bike world. This bike inherits the unique character that XBs have and takes the whole package to a new level of performance. What's to hate on? Eric's bike is rad. I've ridden it and there is nothing else like it on the road right now. That's enough of a reason to build it right there. (Message edited by stevelknivel on February 14, 2013) | ||

Xxxue |

nothing like on the street come on ! any current 1 liter sportbike either tops or equals it for hp. torque is the only area thats tops the current 1 liter sport bikes and those numbers are totally useless. | ||

Andersonhdj |

As was stated, you're missing the point! quote: (nothing like on the street come on ! any current 1 liter sportbike either tops or equals it for hp.) Who cares - this is about Buells not Riceburners. It's about bikes with character! I don't think the object here is to beat allcomers, it's about enjoying your Buell! | ||

H2opatrol |

Mother of god man...... you realize you're "that guy" right xxxue? | ||

D_adams |

Xxxue = Troll. Just wish there was an ignore button to click so I wouldn't even see it's posts. | ||

Buford |

Torque makes one smile.. | ||

Whitetrashxb |

damn straight.. rock on Eric! | ||

Arcticktm |

Ericz, You are clearly miles beyond my capability/ambition, but in case you have any troubles fitting the E-One clutch, check out my Knowledge Vault post on my experience. http://www.badweatherbikers.com/buell/messages/384 2/456488.html?1272473363 I simply wanted to replace my burned out stock '06 XB12X clutch pack with Energy One, but it was not a direct replacement (contrary to what they stated). Ended up keeping their fiber plates but having to buy stock HD sportster steels to get the right pack height. I imagine you are way beyond this, but just in case I can save you some time. I also chucked their "extra plate" and went back to stock judder plate style after having some launch issues. Again, all with a tame stock motor, of course. | ||

Xxxue |

Heres what you could be doing with a Hayabusa http://www.youtube.com/watch?v=QRpy5gKLLDA | ||

Srwitt |

Thats what everyone could be doing with a Hayabusa.... | ||

Ericz |

Thanks, Arcticktm! I'm actually not real sure what clutch pack I'll be putting in there. I spoke with Kent, the owner of Energy One and he is sending me a "box of parts" to try out. He was so interested in what I am trying that he's just sending them to me, no charge  He is such a nice guy and generous! I'll be checking everything over as I build this clutch to make sure it's just right. He is such a nice guy and generous! I'll be checking everything over as I build this clutch to make sure it's just right. I just compared a stock XL pressure plate to a XB pressure plate and it seems like they will swap out (XL fits on XB but not other way around). I just ordered a Barnett machined pressure plate for an XL and I'm going to compare them all and use the stiffest plate to minimize deflection with the heavy spring. | ||

Ericz |

Here are some pics of the bike I took today. She's lookin good, I must say        | ||

Buellblastrider |

Looking very good. | ||

Greg_e |

It's a very clean build, you should be proud of your work. | ||

Xb9er |

Hard to slay a dragon on a big dumb busa. XB looks amazing! Well done sir |