| Author | Message | ||

Ericz |

So despite running into lots of small problems I have made progress on the bike. I am working on fixing my Aquamist water injection pump. Just recently it stopped pumping and it is no longer manufactured so repairing it is proving to be a challenge. I have sourced some electrical components from mouser.com with the help of the guys at Aquamist and will see those on Monday. I have also found another pump/kit on ebay that I am trying to pick up for not too much $$. Either way I hope to have it going again soon. I still have to wire in the new mini O2 sensor, which will happen as soon as I finish the welds on the new exhaust. I will try to get those done tomorrow or next weekend. The rest of the work is small details but it's looking extremely clean and mean! I rolled it off the lift and into the driveway to shoot some pictures and here they are:    | ||

Kdogshirow |

Cant wait to hear how it runs & dyno figures ! And it does look Clean and Mean !!  | ||

Kdogshirow |

Hey Ericz , what kind of rear sets are those ? Rizoma ? | ||

Ducxl |

Wow! Unbelievable...no,really.Where's the turbocharger and intake plumbing? | ||

Kdogshirow |

The Turbo is tucked under the motor where the muffler used to be (you can can see it peeking out the back a little), I dont think he has the intake pipe on in these pics , you can see the hole under the left side air scoop where it runs up through the frame , I think . | ||

Canucklovingbrit |

Ferocious! Looks great. | ||

Ericz |

The rear sets are Rizoma. I really like them! Kevin is right. The turbo is in the same spot it has been since ~2008 or so, under the motor. The intake plumbing is not installed in the pictures but it travels up along side the primary cover through the hole in the bottom of the left air scoop. | ||

Ericz |

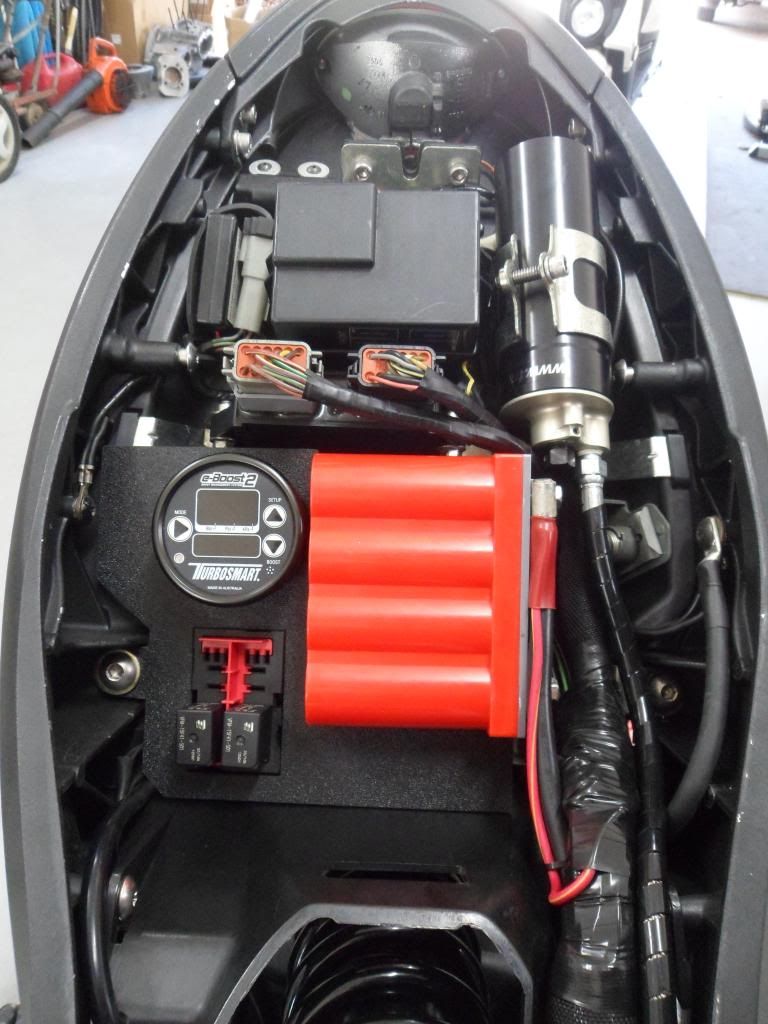

Here are some more shots of what I've been up to. Repairing my Aquamist water injection pump was quite a chore. I ended up buying another used pump and salvaging the controller board from it. I finished up the mounting of my Turbosmart electronic boost controller and associated electronics next to the Alien Motion lithium battery. I also mounted my new ASV levers and the new Nissin radial master cylinder with a cool little billet m/c reservoir. I have spent lots of time getting the new exhaust welded up and things are finally coming together. Making a one piece exhaust header that has to mate to 4 different gasket surfaces out of bend sections is a bitch! I have cut more stainless tubing that I want to remember, Haha!     | ||

Djohnk |

| ||

Ericz |

Here are some shots of the most recent exhaust work. I have been cutting and fitting all of the exhaust tubing and a friend of mine, Roland, has been welding everything up. He has performed of the welding on my bike since I began the project over 6 years ago. The exhaust is made from pieces of two stock headers and new 304 mandrel bends. The primaries are 18 gauge 1.75" diameter (same as the stock US XB12 header) and very close to equal length at about 17" long. Both primaries have a bung for an EGT thermocouple installed 2" from the exhaust flange. The collector joins them to a single 16 gauge 2" run down to the turbine inlet. The wastegate branch is 16 gauge 1.5" diameter. The turbine outlet tapers from 2" to 2.5" and bends around to the slash cut outlet. The wastegate merges back with the turbine outlet at the bend. There is a mini O2 sensor bung in the top of the 2-2.5" transition right as it exits the turbine housing. I also added a length of 2.5" aluminum to the inlet of the turbo to position the air filter further forward and allow for a larger filter. We had a difficult time getting everything setup to back purge the exhaust for all of the welds since the exhaust has had to be installed and uninstalled many times between welds to verify fitment. Instead, we have used Solar Flux to shield the insides of the weld joints and it has worked well. So far, I have spent close to 15 hours cutting and fitting at my house and we have spent over 12 hours welding and fitting at Roland's shop. Building an exhaust like this is no easy feat! The rear primary is made up of four out-of-plane bends which made it a PITA getting everything to fit just right. I am waiting on the final piece of tubing to arrive this week sometime. It's a 2" 30 degree bend that will connect the collector to the turbo plumbing.         | ||

Firemanjim |

Remind me how you are fueling under boost,have a guy here installing turbo on his XB. And what pistons? Thanks. | ||

Kdogshirow |

Ericz , you never stop amazing me with your well thought out quality work . The electronics and plumbing look fantastic . The exhaust outlet just looks mean ! I always look for your posts when I log on to BadWeb because I know they will be good . Cant wait to see more !  | ||

Buford |

Very clean, professional....needs to go into production...  | ||

Ericz |

Jim, what year XB is the turbo going on? Depending on the ECM, you can add a MAP sensor and enable the Airbox Pressure compensation feature. I have a page on my site dedicated to the steps required for DDFI-II ECMs. Here is the link: http://streetfighterperformance.com/xb12-turbo/turbo/map-sensor I have used CP pistons for the past two builds. What compression ratio does he want? Will the heads stay stock or is the chamber volume going to change? Thanks, Kevin!! I'm patiently waiting for UPS to show up with the last exhaust bend to finish everything up. If it gets here in time, I'll be putting her on the dyno on Friday to get a base tune in before I put a few hundred break in miles on her at low boost. Buford, I wish it would be a profitable investment! These kind of projects are what I'm passionate about and there is nothing better than making money doing what you love! (Message edited by EricZ on November 07, 2012) | ||

Glitch |

Impressive Eric, very impressive indeed. Quality at it's best, it's looking more and more like it came that way from the manufacturer. Remember to turn the boost where you want it, after the dyno tune.  | ||

Sifo |

Awesome work. I've got 2 questions if you don't mind. 1) What if anything was done to add durability to the bottom end. Is that a concern with a turbo, or can you get the HP without spinning it faster to limit the abuse on the bearings. 2) I'm surprised that you are building new headers for this. Is this just trying to improve on the system you had on the last build? I can't imagine that the old set up got destroyed from the guts coming out of the engine. And please, no oops moments when getting this one dial in. I'd love to see how this works out long term. | ||

Ericz |

Haha! I'm going to try to not push too much boost  The bottom end is a 2008 crank with Carrillo rods and the Screamin' Eagle Lefty crank bearing. I am keeping the redline at 7500 rpm so there won't be any extra load on the crank from more rpm, just power. The old exhaust system did survive the engine failure. The new system is just an effort to improve the overall design. It sends the exhaust to the turbo through a more direct route with fewer and larger radius bends. | ||

Ericz |

I got the exhaust finished up last night and played with the tuning today. The last exhaust piece welded up perfect and I am very happy with the results. After getting it to idle and run decent in the garage, I realized that the turbo spools much, much, much better than it did with the stock header and turbo mid-pipe. I am so excited to see what she does once I get the motor broken in. It sounds great and is exactly as I hoped! Tomorrow will be a bit more tuning and then I'll get Jennifer to shoot a video of the bike and all the new goodies. I had my helper with me in the garage today too:     | ||

Kdogshirow |

CANT WAIT !!  Video Please ! | ||

Motorbike |

Ericz, your dog does beautiful work. Can I hire him? (or her?) What a fine example of professional craftsmanship at it's finest. That bike is so cool! | ||

Ericz |

Thanks, Kevin and Al! Sammie is for hire and she works for food so as long as you have bacon, meatloaf, or pizza she would be happy to work for you! I've been playing with the bike over the past couple of days and resolving problems as they show up. The first problem, and the most frustrating, was the "new" used Aquamist pump broke. The epoxy inside the coil of the pump broke apart, allowing the windings to rub and short on the outside case. After taking the pump apart and discovering the problem, I have decided to give up on the old Aquamist pumps and go to the newer pump model. I will have to fab new mounting brackets and rewire the harness but it will be worth it. I will now be able to source replacement parts should I have any future issues with the new pump. I have made several test runs after making small changes to the fuel mapping. The larger injectors are working very well for idle and part throttle conditions and the fuel mapping is quite different than it was before. Another interesting change is the throttle % required for the correct idle speed. Previously, it wanted around 4.5% for a 1000 rpm idle speed. Now it wants 2.3% for the same idle speed. I have verified that there are no intake leaks and the only ideas I have for what would cause the difference is 1) the larger valves or 2) the new exhaust design spinning the turbo faster at idle than before resulting in less restriction from the compressor wheel. Either way, the bike is running very good and has very crisp throttle response. I ran out of time today for a video, but tomorrow I will definitely shoot one. It's so cool! | ||

Glitch |

I'll bet it sounds awesome too. Very nice work. Do you have any idea the total hours you've invested? | ||

Greg_e |

What is the extra exhaust outlet down by the turbo doing? | ||

Glitch |

Wastegate? | ||

Ericz |

Geez, I think I may have around 200+ hours in the most recent build, may be more  Glitch is right about the smaller exhaust outlet. It connects to the external wastegate. | ||

Ramairz |

Looks great! Love seeing other people into custom fabbing! Can't wait to see the finish product | ||

Ericz |

Today, I worked with a friend and shot a video for you all to see and hear the bike. He is going to edit it over the next few days since we took video with three different cameras. He is pretty good at shooting and editing video so I'm excited to see it put together. It's going to be a real short one but I plan to get his help to get some good action footage for the big blockbuster  | ||

Motorbike |

Okay, we are on the edges of our seats!  | ||

Ourdee |

| ||

Ericz |

I spent more time today tuning and came across another issue. The diaphragm in my Turbosmart FPR is torn. Of course, Turbosmart no longer makes it nor replacement parts for it, but I called the US office and they will replace the entire FPR with their latest model for free! Wow, what great customer support! They took care of my boost controller issue and now they are going above and beyond with my FPR. I am so glad to experience business like this! |