| Author | Message | ||

Pauley2000 |

My 09 XB12XT jammed at the end of a run last weekend. Clutch stuck. Need a new side cover. Anyone else hear of this? Or is it an isolated incident. Bike had been working perfectly prior. -p | ||

Brother_in_buells |

If this is the problem you have!? http://www.badweatherbikers.com/buell/messages/384 2/282980.html?1341400136 Welcome to the club then! | ||

Pauley2000 |

YES EXACTLY! Thank You. So a frequent occurrence or relatively rare? -p | ||

Brother_in_buells |

It is more common than we would like ,in some cases its because the clutch ramp is adjusted to tight and also the edge in the primary cover can not handle the force from the clutch spring/hub. But it's good repairable and after that it's better like before. You can contact http://www.badweatherbikers.com/cgibin/discus/boar d-profile.cgi?action=view_profile&profile=gunut75- users he has done some primary cover repairs. | ||

Joel9 |

gunut75 repaired mine, probably will never break again. his repair looks bullet proof and was less than half the cost of a new primary cover. | ||

Natexlh1000 |

Do sportsers pop like that too? | ||

Brother_in_buells |

Joel9 ,did you take a picture from the repaired cover before assemble? Natexlh1000 ,its a XB issue the good old tubers don't have that problem  | ||

Joel9 |

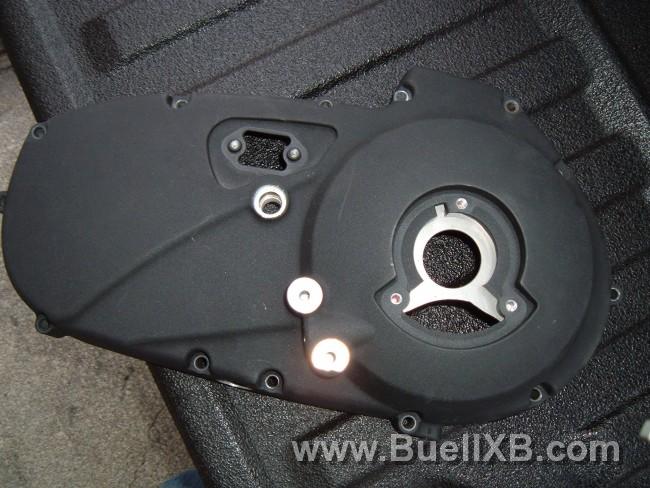

Yes...   | ||

Brother_in_buells |

Joel ,thanks for posting that! | ||

Teeps |

Are the adjustment cover screw holes threaded all the way through the case? | ||

Greg_e |

Maybe when you machine the area down it will cut them open, if not you need to drill and tap. | ||

Capitantem |

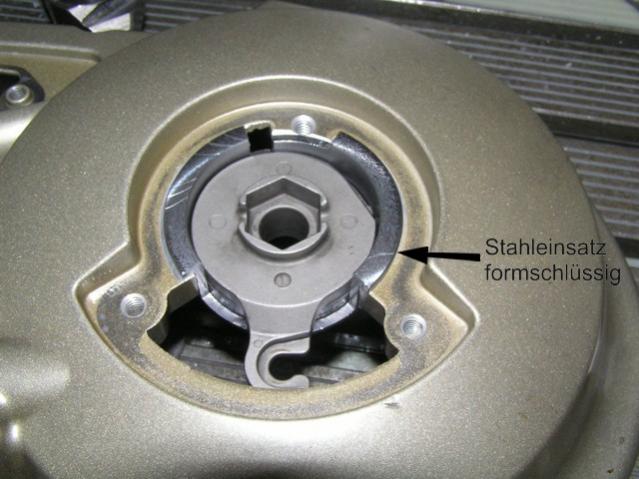

That's another solution from the german forum http://www.xborgforum.de/forum.php Don't know the details about it, I don't speak german.   } | ||

Gunut75 |

1) Run a #7 drill from the outside and put the holes all the way through the cover. 2) Chase the threads all the way through with a tap (from the outside of course). 3) Flip the cover and flatten whats left of the old lip on the inside. I use an endmill and machine fixture for this. Total Material removed is about .04-.06 (depending how the lip broke). 4) From the inside, use an 82 degree countersink and chamfer the 1/4-20 holes. 5) Take (3) 1/4-20 x 1/4 flat head socket cap screws and turn down the heads of them in a lathe. I also use the 3 jaw chuck on the lathe at this time to slightly deform the threads on the screws (this and red loc-tite are what holds all this together). 6) Take the plate that Joel9 has in his pic there and screw it to the cover. Tech tip: The plate I use is .074 thick, and the head of the screw after lathe work is about .1 The plate is chamfered enough that the bottom of the screw heads actually protrude out into the cover casting. This is the reason for chamfering the holes in the back of the cast cover. If you dont have enough chamfer in there, the repair plate will never fasten properly to the cover. It wont tighten up. Thats how I do it. If you want a sketch of the plate (hole position and what-not), I have one on photobucket I think. I will gladly send it to you if you are able to fab the repair yourself. There ya go, and you still use the stock "omega" cover screws. Cheers y'all.  | ||

Teeps |

http://www.fanatics-parts.de/go/fanatics/_dbe,prod ucts,bf-dienst_primaerrep1,l-en.xhtml google translation: there are resourceful people among our Buell joys, because after the primary covers the nose more often erupt for the clutch and mimic the cover is a case for the furnace then, a solution was needed. The cap is milled erupted in the coupling receptacle and replaced with a steel insert. This time without the stress concentration and with radius in the crucial corner. That the tool steel has a 3-fold higher tensile strength was incidentally mentioned. Additionally, the steel part is based on the still from the support bars 6 in the back of the cover are integrally molded. The original seal fits continued, the Omega lid covers the insert completely and does not need to be reworked. The defective clutch cover must be sent to us to edit, maybe we have a replacement in there. Please ask in advance. Either way, you save yourself so that a new primary cover and the thing keeps forever thereafter. |