| Author | Message | ||

Ericz |

I pulled my blown motor apart over the weekend to survey the damage. It was neat to see everything that the broken rod hit! I have decided to not go for the 1470cc big bore build so that the cases don't suffer from the loss of structural material around the cylinder spigot holes. I picked up a 2007 XB9 motor from ebay that is in great shape with 11k miles. I am going to use the case with a 1250 kit from NRHS with a 9.5:1 CR and install a 2008 crank with Carrillo rods, XB12 primary gearing, and replace the tranny with the old style straight cut gear set. I have the crank and will send it to Darkhorse Crankworks tomorrow for John to install the rods and do some machining/lightening. Evolution Industries is building a clutch hub/plate assembly to hold the new power.     I wanted to compare my 2005 oil pump to the newest design "improved" 2007 oil pump and I found something interesting. The 2005 pump has a smaller diameter and shorter scavenge gerotor set, and a keyed separating washer. The 2007 pump scavenge and feed gerotors share the same diameter and so the pump bore is uniform top to bottom. The separating washer is not keyed, and is allowed to rotate with the gerotors. The washer is stamped steel, and with it's rough finish on the o.d. it wears at the inside bore of the pump body. I want to either install a new 2007 oil pump and try to modify the separating washer to stay stationary or keep with the 2005 pump. Hmmmm... 2007 pump on left 2005 pump on right  2005 pump with key for separating washer  2007 pump with groove worn into bore.  | ||

Ericz |

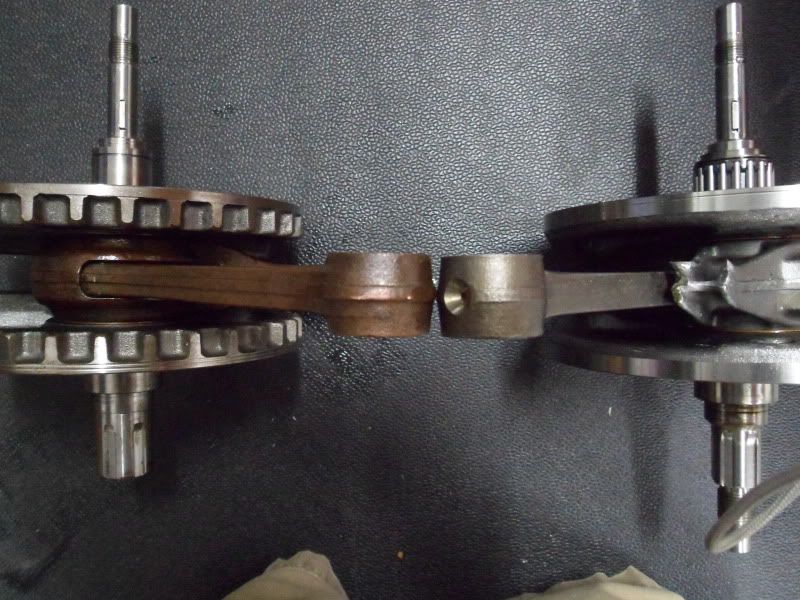

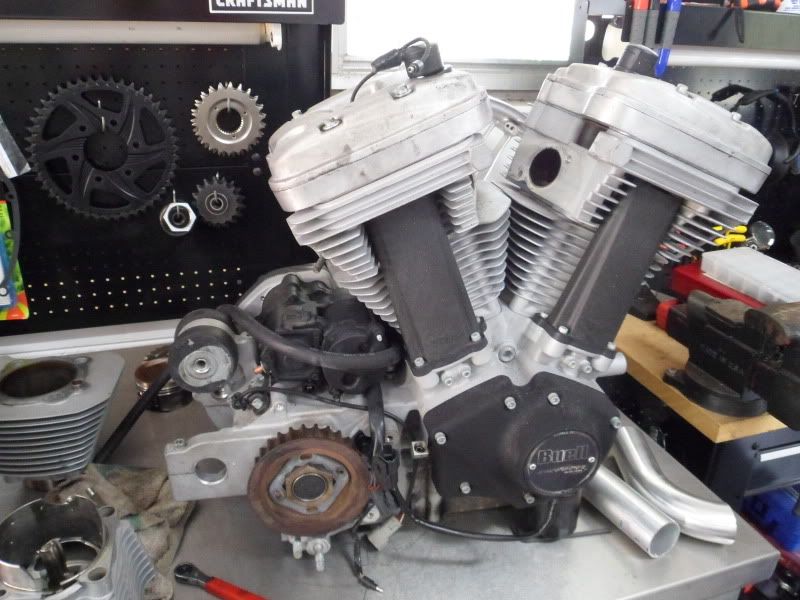

And here are some comparison shots of the 2008 crank vs my 2005 crank with the broken rear rod:      Here is a damage shot of the rear cylinder with broken connecting rod and piston still in:  Here is the 2007 donor motor that I will build up with the 1250 kit, etc.:  | ||

Slaughter |

What John CAN do is to put a static timing mark on the flywheels after they're lightened and balanced (HIGHLY recommended) Working on very similar mods - but keeping short stroke/big bore (1169cc) so she'll spin up quicker. The bigger bottom end is a big plus with the later flywheels. Interesting destruction. USUALLY it's the big end that starts failing, not the C-rods. One suggestion: clean up case half and mount a clock to it. Makes a cool wall clock - and you'll get asked LOTS of questions about your "new clock." | ||

Natexlh1000 |

WOW. That rod was in a hurry to check out! | ||

Greg_e |

Does the shaft on the 07 pump still have a flat spot? You could cut a new washer with a flat so that the washer isn't loose to fly around and wreck the sides of the pump housing. It would still spin but you can now control edge clearance (unless I'm not understanding the way the pump works). | ||

Johnboy777 |

Hey Ericz What size motor will you end up with? And why the 9.5:1 CR? Thanks | ||

No_rice |

And why the 9.5:1 CR? the big old turbo that hangs off the bike. | ||

Ericz |

Steve, I will definitely have John machine a new timing slot! Greg, The pump shaft is not concentric with the pump bore, so the washer would have to be held by either of the outer gerotors to maintain an edge clearance. Johnboy, The motor will be 1250cc, and the lowered CR is for the planned 20psi of boost from the turbo, like Tim mentioned  | ||

Reepicheep |

Great pictures! If you are going to go, go big! :0 | ||

Froggy |

Thank you for those pics and info, I will probably be heading down a similar route as you with that disassembled motor I just got. This is gonna be great!  | ||

Firemanjim |

Hey,Eric,was this motor boosted? My 88" turbo engine had a rod failure just like that. | ||

Ericz |

Yup, this is the one that hit 187hp at 15psi. I posted the dyno videos and tear down video after it blew on here too. | ||

Reepicheep |

Different cranks *and* rods on the 2008 huh? | ||

Johnboy777 |

Hey Ericz Any chance you have the HD part # for the '08+ crank set up? I need to order one. Thanks | ||

Cataract2 |

Well, I think when/if I get a Uly it will be a 2008+. That or a 2007 that I could upgrade to an 08+ internals. | ||

2kx1 |

Does anyone know for sure if that crank will fit in a tuber case? | ||

Ericz |

Johnboy, I don't know the part number off hand but the XB12 and XB9 cranks are different, if you didn't already know. What bike do you have? 2kx1, not positive but I think the cranks are significantly different. I compared the output shafts of a 2001 XL and my XB and they were much different. | ||

Kdogshirow |

Ericz , its good to here from you , and great pics . I have been wondering how your motor rebuild was coming . My experience with Nallin Racing has been very good , they have fantastic knowledge of these motors and have done it all with them , I am sure they can help you with whatever you want to do . Cant wait to see how it goes . Have you figured out what to do about that famous intake balloon coupler ? lol , just kidding . (Message edited by kdogshirow on September 29, 2011) | ||

Bike_pilot |

Don't '08+ models use a different (better?) oil pump from '07? Perhaps that's one route for an upgrade. | ||

Ericz |

Kevin, I have the throttle body coupler problem solved, and I sure hope that I do right with this build! Bike_pilot, the '08 models do have a "better" (in my opinion) oil pump configuration, but it requires the DDFI-3 engine management as it gets rid of the cam position sensor. You might be able to do the change over, but it would require that you change over to the DDFI-3 ECM and a new wiring harness. Loads of work! | ||

Greg_e |

I can't remember exactly what position sensor looked like when I changed my pump drive gear, but wouldn't it be somewhat easy to machine the rotor attachment on the end of the 08+ crank as long as you are using the pre-08 cam cover? | ||

No_rice |

Yup, this is the one that hit 187hp at 15psi. I posted the dyno videos and tear down video after it blew on here too. but i dont think that was the problem was it...?! wasnt it because after that run the boost controller got cranked WAY WAY up while trying to figure out why it wouldnt build more boost? then after finding the coupler loose, and fixing it, the boost controller didnt get turned back down before you took it out for a test run? id like to know what that thing was running when it blew if it was running 187 and staying in one piece lol. | ||

Ericz |

Sure was, Tim. I will be pushing the new build to around 20psi, and I think that I will see somewhere between 210-230hp at the wheel.  | ||

Motorbike |

Ericz, that is amazing! Please post a video of your dyno runs when you are done with this build. I would love to see that. Thanks! (Message edited by motorbike on September 29, 2011) | ||

Tiltcylinder |

WOW!, did that connecting rod want out of there. How fast are you able to spin an inherantly unbalanced, blown, big bore n turbo'd twin? Did that happen at speed... no don't tell me... makes me shudder | ||

Ducxl |

No way in a million years.Eric is racing to mechanical failure.I absolutely LOVE an engine build too.My 996 is around 140RWHP,BUT,it's engineered for it. Sorry...I do not wish to be a downer.Your numbers are unrealistic | ||

Kdogshirow |

Ducxl , you need to look at the youtube vids we all have seen , and his other threads , he got real close to 200 hp before , why is that not possible with a new motor with stronger mods ? Ericz original turbo motor was pretty close to stock . A Buell 1200 with a air filter and pipe puts out more torq than you Duck 996 anyway . Plus more CC's and a Turbo w/20 lbs boost ? Durr? And speaking of unrealistic numbers , a stock 996 puts out around 113 hp and 70ft lb. torq . see link - http://www.bikez.com/motorcycles/ducati_996_2001.php (Message edited by kdogshirow on September 30, 2011) (Message edited by kdogshirow on September 30, 2011) | ||

Bike_pilot |

Ducxl, one thing to remember is that its much easier on a motor to make power from boost as opposed to rpm. Still more strain than stock, but no where near as much strain as a high-rpm NA race engine. For example, on a TL ~150-160hp is the limit on a NA engine because the cases will break before you can rev it high enough to get much past that. Folks have done 200hp on modest boost without any trouble at all while keeping red-line stock. Also, 140hp would be a really exceptional 996. Last 998 I saw dynoed in person did 115 - that was with aftermarket airbox, termis and ECU. I'd absolutely love a small turbo for my Uly. An aerocharger mounted where the front bit of the muffler is would be pretty awesome I think. Maybe next year... | ||

Ducxl |

I just don't think the rotating assembly can handle the power.THAT it CAN make the power i don't doubt.I'd think XBRR cases would work somewhat better.You'd need the WHOLE package. The 996 has modified 14:1/SPS cammed ported etc. A stock Buell engine is a reliable engine.Not much more to be gained w/o loss of reliability.Best of luck.I failed at my 89" XL build.It kept breaking |