| Author | Message | ||

Wavex |

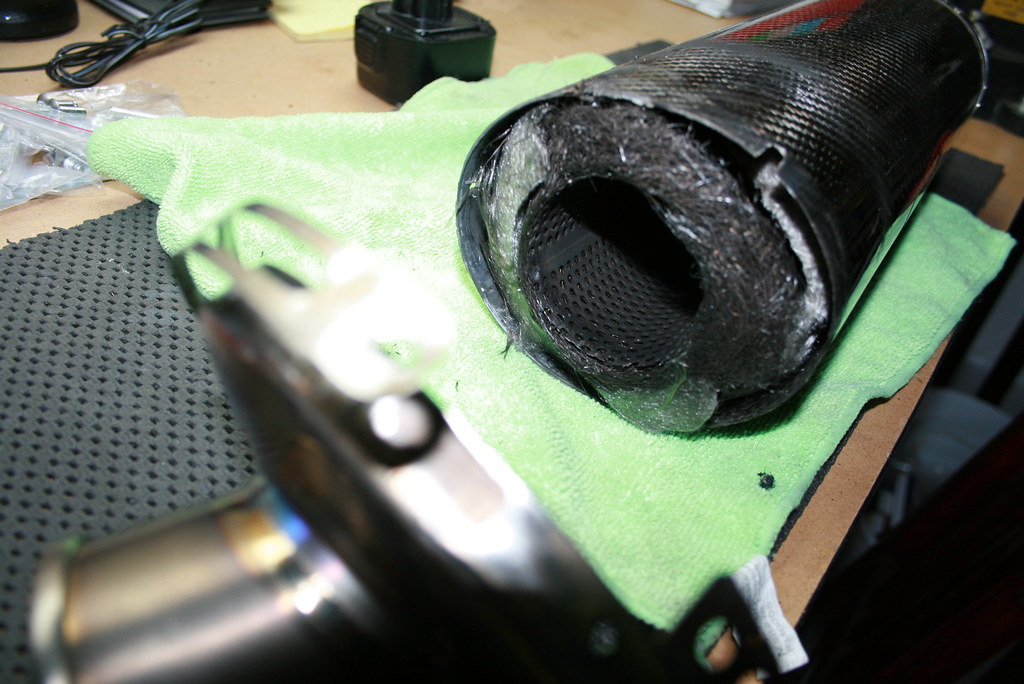

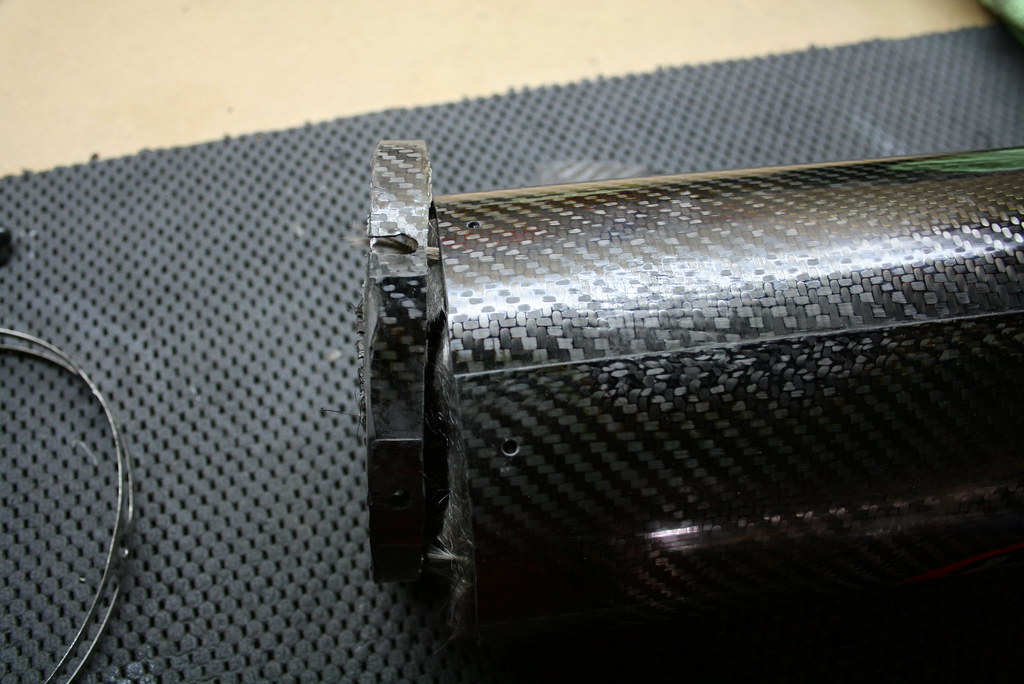

Like many others my Jardine's exhaust tip popped out (1yo pipe...). I caught it just in time so no other issues, but I have 2 questions: 1) how to fix these holes? 2) What re-packing wool is best for this pipe? I am thinking of shortening the CF to eliminate the old holes and drill twice as many holes for the new rivets... Any better idea?   | ||

D_adams |

Looks like you have stainless and fiberglass packing. E-glass or Spec 30 would be better for longer durability. As far as repair of the holes, probably not, just drill new ones, but it will end up doing the same thing in another year or so. That's just the nature of CF when it gets vibrated and abused. | ||

Wavex |

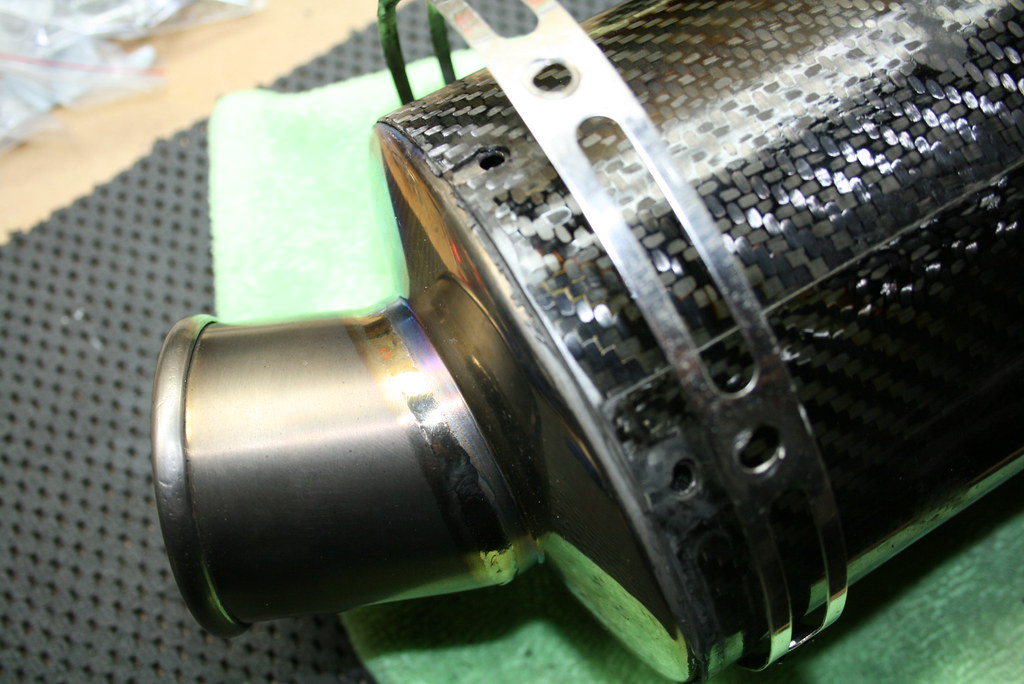

Thanks. Do you know if I can get that E-glass or spec 30 from local stores? So basically dremel 1inch off the CF and go for new/more holes... I just need to figure out the metal ring situation (it has specific hole locations, 6 of them only). | ||

Teeps |

How was the tip [sic] originally retained, pop rivets? If so, I would leave the can length as it is and reinstall, the tip, with twice the number of rivets. I would go with stainless steel rivets. | ||

Pogue_mahone |

get a tube to go inside and attach rivets to that.and you still retain the appearance of the CF.and use more rivets to spread the load of the rivets over a larger area. | ||

Wavex |

adding holes is tricky due to the outer metallic ring:  I guess I can add washers ?? Yes they use SS rivets. As for the inside, the tip goes there... see above. They use a rubber based sealant, which looks good on the front (inlet)... guess I need to find a good high temp. sealant as well. | ||

D_adams |

Use the ring as a template, mark it with a permanent marker. You just need to squeeze it tight around the can to do the marking. Once thats done, trim it back some, drill the holes, new pop rivets. You can get the Spec 30 from Bristol Core. http://www.bristolcore.com/product_p/14214.htm It's also available in a mat form. I use the loose stuff myself. Spiral winding around the inside tube works best from what I've seen/heard. Just jamming it down in the can won't last as long. | ||

Wavex |

Thanks man much appreciated!!! | ||

Union_man |

I would reconsider my pipe choice. | ||

Drkside79 |

+1 I would reconsider my pipe choice. I have heard nothing but bad things about your pipe. Also that has got to be a dangerous thing to have happen while riding. | ||

Cryptic1911 |

Someone should make some "suspenders" out of wire for each end. make a ring that goes around the inlet & outlet pipes, and then have hooks coming off of those rings, and up over the edge where the rivets are, then run wire from the front to back hooks and twist together to keep the tip from working itself loose from the can | ||

Terrys1980 |

Cryptic I like your idea. Another idea would be to use 1/2" strips of stainless connecting both ends at the rivets. | ||

Keys |

Cryptic, great idea I'm going to try it with race wire and see if my new one holds up. From the posts that have been made thus far and from the warning sticker that Jardine puts on the carbon fiber pipe stating that the CF pipe is for race applications and has a purely lightweight emphasis only. I've concluded that they aren't intended for those seeking long-term durability. It is so light I have no problem preparing my budget to purchase a new one next year - if needed. (just like tires on a track day) It's just the price of ultra light. If you do an ebay search you can find them 100$ off msrp.. | ||

Delta_one |

I too like the idea of race wire to hold it together but I would run it on the inside through the packing, you are in there anyway. | ||

Wavex |

UnionMan & Drkside79: nah, not only bad things... they sound awesome, they weight nothing and look great! Plus I MUCH prefer the power band compared to stock! They are a bit fragile, but I have to admit that I did not repack them after the recommended 4k mark, and I definitely abuse the throttle a lot  Great idea about the race wire... not sure how to run it on the inside of the can, but I'll figure something out... Using the dremel on CF is ok? | ||

Union_man |

There are better pipes. In the performance shootout (http://www.americansportbike.com/) the Jardine was sub-par. A race pipe or a chopped pipe (Drummer, Special Ops, or homemade) sound better and they don't blow apart! Your bike, your life. My $.02 | ||

Aptbldr |

Since you don't plan re-packing; before rivets, prep surfaces & apply adhesive between carbon fiber can and rings & end caps. | ||

Delta_one |

put hollow rivets on both end caps and string through. or better yet tack weld a washer to the inside of the front cap and a hollow rivet on the back and string through. I would use 3 strands at a minimum spaced evenly. | ||

D_adams |

What are the dimensions on the can? 3.5"x10" or longer? I could maybe make a replacement shell in stainless if you want. I have either 3.5" or 4" shells, but I would have to weld 2 together for a longer can. Depending on the location of the clamp for holding the can, you might never know it was 2 shells welded together unless you took off the clamp.  (Message edited by d_adams on March 15, 2010) | ||

Wavex |

Union Man: sub-par based on what? peak numbers? I could care less about a 5% variation in peak numbers (which your butt dyno can't really feel anyway) and care more about the overall aspect of the HP/torque curves and especially in the low and mid-range, in which the Jardine does very well. Either way, you are right, there are surely better pipes out there, but right now the "easy" and cheap solution for me is to fix my Jardine the best way I can, and in parallel to gut my stock pipe completely to make it look like a drummer (don't want to spend $300 to get it done). Aptbldr: I DO plan on re-packing. Read above. I will use adhesive though thanks. Delta_one: great idea... I think this will be my preferred solution thanks... D_adams: Thanks! the Jardine pipe is actually oval and measures 15" x 5", so I don't think any of your shells would work... your help is much appreciated though. | ||

Delta_one |

glad I could help. let us know how it worked yea? | ||

Wavex |

Some progress   (Message edited by wavex on March 18, 2010) | ||

Cthagreekgod |

What about drilling two small holes on either end (inlet side and outlet side) and running a legnth of all thread right through the pipe, and putting some "liquied high temp gasket" on a washer, and bolting it there. hat way any pressure would have the effect of pulling the inlet and outlet sided against each other, and neither should pop out... similar to the wire idea, but a bit more rigid I would think... | ||

Wavex |

You mean running threaded rods through the whole length of the can? Yeah that would work too... Right now I am trying to see if the inner mesh tube can be welded to the inlet side... If I can make that happen, then all I'd need would be 3 little brackets which I would weld to the inner mesh tube on the outlet side, and rivet their other ends with the exhaust tip/can... That way I'd be using the inner mesh tube as a rigid link between the inlet and outlet tips... | ||

Greg_e |

How about this for an idea: Drill the holes out bigger and then fill them with a good epoxy. Then drill them back out at the correct size so that you have a big ring of epoxy to help hold the CF together. You might also pick an end and glue the cap into the CF with epoxy which would help spread the load across the entire area. Not sure how you would repack it, maybe from the front but I have a feeling that the front would blow out next. You could also get ugly and run some straps from front to back to hold the ends on the CF tubing. | ||

Wavex |

We're back in business      |