| Author | Message | ||

Jerseyguy |

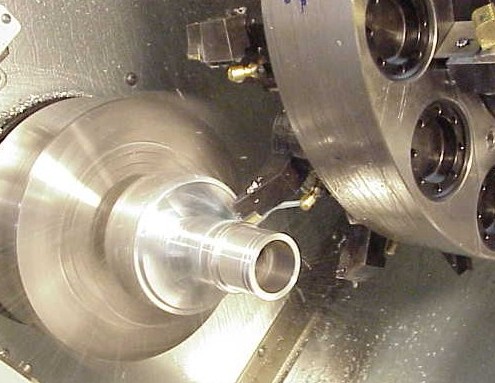

I just couldn't wait any longer so I broke into my production today and made my stack. It's the same geometry as the stocker but aluminum. I don't know if it will be any better but I guess we are going to find out. I'm hoping Bubba will dyno it for me. As I recall his max dyno reading was 79.9 HP. I'm hoping I can at least get him into the low 80s HP range. Steve     edited by blake on January 25, 2004 | ||

Prof_stack |

Looks awesome!!!!  Let's see that dyno result! Let's see that dyno result! Hey, why don't you see how many BadWeb XB'rs want one and cut us a deal?  Prof | ||

Easyflier |

Steve, 2 questions: How hard is it to change some of the dimensions/design? How much would you be willing to sell them for? (Assuming you've considered that) | ||

Hardluckxb |

great work!!! I cannot wait to see the dyno results. I want one! | ||

Dasxb9s |

WAY TOO COOL!!! I'd think that the airflow dynamics would have to be better than over the stock one. I'd like to consider owning one depending on cost... I am trying to not end up in bankruptcy court... so don't count on me as one of the first in line... did you do more with the lift adapter to fit the XB? | ||

Jerseyguy |

Let's see how the dyno runs go before we get too excited. It might just be a pretty part. If I told you what this first one cost you'd think I was nuts. I really just made this one for myself. Before I would consider selling anything on Badweb the appropriate arrangements would need to be with the owners. It's only fair as this BBS has costs of its own. Steve | ||

Dasxb9s |

I do have a bit of a clue... I bet the man hours alone at this point would scare most people... You sure you don't want to relocate to Missouri... and become a KC Mob member?? :-) | ||

Easyflier |

I understand, I didn't know if you slipped it in or had your own machine shop. I remember someone speculating that the 12 stack is shorter than the 9's. Not sure if that's true or not but if it is maintaining the corresponding gap between the mouth and the airbox cover would probably have an affect on performance. | ||

Fullpower |

ooooh jersey thats pretty. make a bunch of them. | ||

Wyckedflesh |

Jerseyguy...are you running a 12 airbox on your 9 for use with that stack? | ||

Jerseyguy |

My XB9S is truly a "BadWeb Special". I read all your posts and decided on the following stage I performance mods. Race ECM (& TPS reset), K&N, snorkle removed, DRUMMER, & 12 airbox cover. Das - I may take you up on that someday the way the cost of living is here in the Northeast. BTW, I forgot about those jack crescents. Easy - Yes, I have a custom machine design and manufacturing company. We make automation products mostly for the medical industry. Earlier today I asked Bubba to measure the 12 stack height for me. Wickyed - Yes (see above) | ||

Awprior |

Jerseyguy, Is that CNC? What modeling program did you use for it? I can toss stuff like that out on Pro/E, just need the machinery! | ||

Henrik |

Steve; that is fantastic work. Looks great - make more  Henrik | ||

Bluzm2 |

Steve, That is a VERY nice piece of work. Well done. Damn shame it will hide under a cover...... Brad | ||

Awprior |

It is a shame to hide that under a cover... Too bad you can't polish it up and show it off... I guess a clear airbox cover would be different. It would be interesting to see if there are any significant changes in power based on geometry of the stack. | ||

Jerseyguy |

Awprior - Yes it is CNC - the only way to go on a complex shape like this IMHO. We use SolidWorks as my 3D CAD software and AutoCAD for 2D. The CNC machines have their own software that translates the SolidWorks to a profile. The CNC operator then selects methods, tools, speeds, etc. and completes the CNC program. I plan to get it clear anodized as well. I have to wait a bit for anodizing so I can send it with other parts. Otherwise the anodizing alone would be over $125 (due to set up charges). I really hope there is some performance gain to make the effort worthwhile. I used the stock geometry because I have to assume that Buell engineers know way more than I do on stack design. I have also modeled a different, more complex profile based on constant acceleration of the air as it passes through the stack. I haven't decided if I want to go through the expense of making it though. I'll start another post sometime soon so you all can offer an opinion on the design concept. edited by jerseyguy on January 24, 2004 | ||

Buckinfubba |

jersey you have mail | ||

Gonen60 |

It's the same geometry as the stocker but aluminum First off, that looks like fantastic work...AWESOME job..just curious, why would there be, or why expect any gain in performance, if it's the same geometry?..would aluminum produce more HP over it's plastic counter-part? great job all the same..now you just need a clear airbox cover and clear inner box cover so you can see it..um, clear airbox cover?...LOL | ||

Xb9er |

Amazing work. It's going to look great when clear anodized. I would definitely buy one. Gonen60--the stock stack is a flexible, "rubberized" piece that distorts/doesn't maintain its shape, therefore airflow is less than ideal. | ||

Jerseyguy |

Gonan60 - Like XB9er said the stock stack is made of rubber (buna n, or possibly neoprene) and does not hold its shape well. I measured a 1/8" ovality on its bore and a 1/16" ripple in the top edge when I checked mine in my bike. My theory is that a "perfect" rendering of the geometry will flow better. We'll see...... | ||

Jerseyguy |

I just read Brian's email. On Monday I'm switching the O rings to Quattro seals because I think they will work better. Then I'm shipping the assembly to Tilleys. Brian will dyno test the stack on his day off after he gets the stack. So we should see some results the week after next. Thank you Bubba & Tilleys  | ||

Xb9er |

That's cool. Can't wait to see the results! | ||

Opto |

Jersey I find the constant-acceleration idea very interesting...very nice product you've made too. | ||

Xb9er |

It's going to be interesting to see how the dyno results compare to the modified "short stack" that those other guys developed. | ||

Jerseyguy |

Here it is installed. Too bad its 12 degrees with ice , snow, salt and sand everywhere. I'm yanking it out and UPSing it to Tilleys today. Steve    | ||

Bads1 |

Steve I will wait for Bubba's results and then you have a interested Badweber meaning me for one for my 12 if the results are as good as that thing looks.Good job I hope your hard work pans out for you. Dana AKA BadS1 | ||

Fullpower |

very nice. pretty aluminum. does the stack seal to throttle body with orings? | ||

Jerseyguy |

Opto - I'm going to start a thread on my idea when I get a bit of time. I pulled out my old Fluid Mechanics book from college over the weekend. I forgotten all of that stuff after 30 plus years. I do know that there is alot more to this than meets the eye. Steve | ||

Jerseyguy |

Fullpower - No I didn't use O rings. I'm using Quattro Seals. I think its a more positive seal for this application. Steve edited by jerseyguy on January 26, 2004 | ||

Jerseyguy |

Easyflier - Bubba emailed me the dimensions on the 12's stack. If he measured right & I figured right, the 12's stack is 0.454" bigger at it's max OD on the top and it is 0.160" taller. There was a claim made that shorter is better (that's not what the emails I get every day say!) All kidding aside, from what I've read on some automotive sites, velocity stack length can be used to tune the RPM where peak torque is found. |