| Author | Message | ||

Skully |

Thanks Ryan! Keith | ||

H2owerker |

Thanks guys! Contouring the frame was much more difficult than I expected. After I discovered the dent in the right side I was left w/o anything to visually compare, and had to use my best judgment as to what curvature was right. That was mostly done using the 'Hellen Keller' technique. I'm sure that buffing the frame will help even out the appearance of the paint. I can't do that yet cause the paint isn't fully cured. I'll probably wait until spring to give it a shot. The warm weather, and having it on the bike should make it easier to do. Although the vinyl graphics I'm going to apply will probably mask that area completely. Skully. I sent you a PM regarding your darkhorsemoto License Plate Relocation Bracket. | ||

H2owerker |

Got a quote I can't pass up for painting the plastics, so I'll be dropping those off on Fri. Some vinyl will be cut for me on Fri, and those will be dropped off at the paint shop as well. Got a couple images of the projector headlight housings, created in solidworks, from the fabrication shop today too. (w00t) I'm going to be stopping by there on Sat to make sure we've been on the same page w/ the dimensioning, and to drop off some aluminum plate. | ||

Not_purple_s2 |

Nice work! | ||

H2owerker |

I dropped the parts and vinyl graphics at the paint shop yesterday. Unfortunately the weather here doesn't seem like it wants me to spend to much time on this right now. I'm going to try to get over to the fab shop this afternoon, but it doesn't look likely. Sorry to post about basically nothing. I just don't want this going into the archives yet. | ||

Ryanhook |

for anybody interested this is on e-bay http://cgi.ebay.com/ebaymotors/REMUS-POWERIZER-FOR -BUELL-XB12-R-S_W0QQcmdZViewItemQQ_trkparmsZ72Q3a1 205Q7c66Q3a2Q7c65Q3a12Q7c39Q3a1Q7c240Q3a1318Q7c301 Q3a1Q7c293Q3a1Q7c294Q3a50QQ_trksidZp3286Q2ec0Q2em1 4QQhashZitem160309103729QQitemZ160309103729QQptZMo torcyclesQ5fPartsQ5fAccessories#ht_768wt_1044 | ||

H2owerker |

Thanks for 'lookin out'. But if I'm going that route I'll be picking up a Twin-tec from my local HD/Buell dealership. | ||

H2owerker |

Started reassembly yesterday! I put the tail/wiring back onto the frame. I had pulled it off/out while the frame sat atop 2 sawhorses, and it was quite easy as disassembly usually is. Looking at the frame on the sawhorses I realized that w/o a second pair of hands things weren't going to go very well, and wondered how I could make this easier. Getting the wires over the 'front' sawhorse was going to be tricky w/o anyone the help stabilize the frame. I decided to lay the frame on the floor where the wire harness and battery tray would both be supported. It's had it's drawbacks (working on the floor is never comfortable) but worked as planned. With everything laid out in a straight line, I worked the tail forward pushing/pulling the wires till I could bolt the left/right side rails on, bolt the fan back in, and peg the wire harness to the inside of the frame.  Now I just have to figure out how I'm going to get this up the stairs and out to the garage...which will probably require bribing a friend w/  . . | ||

H2owerker |

Got the frame coupled to the engine/trans today! I was going to continue working but I believe I'm getting carbon-monoxide poisoning staying out in the garage so long. Not to mention work called and may need me to go in... Here's how it sits now.  | ||

Bads1 |

Fantastic Ryan, I didn't realize you lived so close to me. I'm in Racine. | ||

H2owerker |

Yeah you're practically right down the road. WI-32 is only a few blocks from home. And if anyone is wondering. The ratchet strap isn't supporting any weight. It just makes me feel better while everything sways around while I'm torquing bolts. | ||

Bads1 |

Yeah 32 is just a couple miles from me. Frigg'n small world hey!!! | ||

H2owerker |

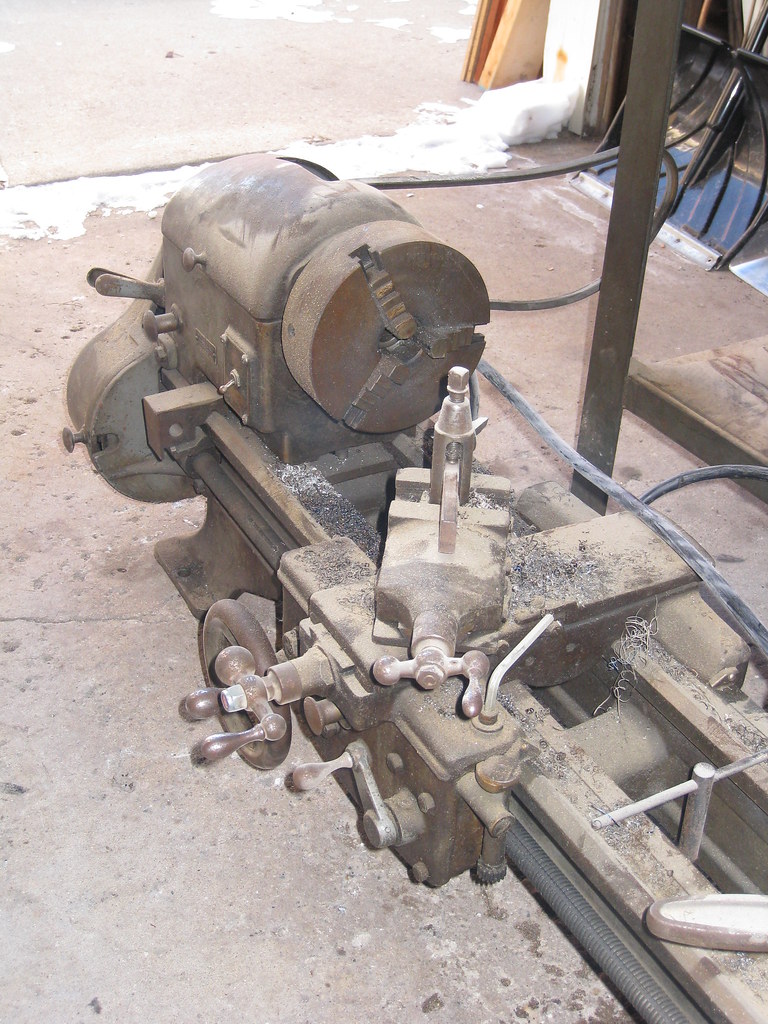

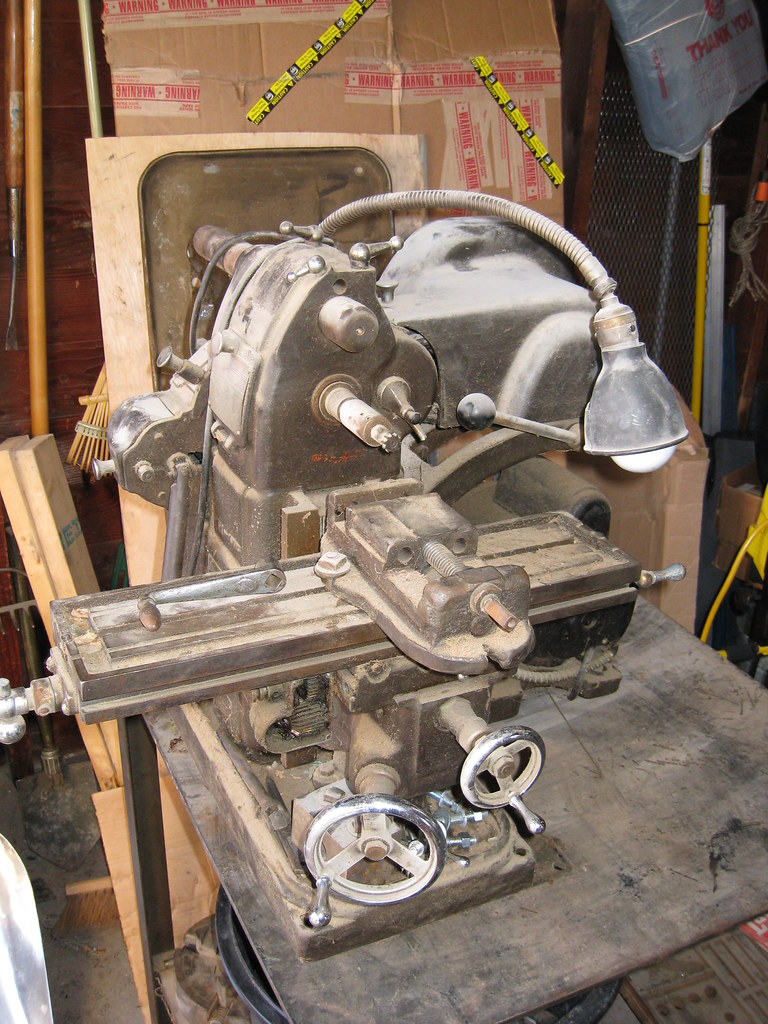

My bike got a couple friends to keep her company in the garage last night. I was lucky enough to get a bench top Lathe and Horizontal Mill from a friends dad for free. I'll post some pics ASAP but just couldn't wait to tell someone. First project=Frame sliders. (Message edited by h2owerker on January 24, 2009) | ||

H2owerker |

Here's the Lathe.   And the mill.  These may require some TLC, and will be sitting idle till the bike is complete. | ||

H2owerker |

I got a chance to check out the 'body' parts this week (Wed.) and can't wait to get them on. I'm still waiting to hear from the fabrication shop about weather or not they started my headlight housings, so we'll see if they get done in time for the "spring reveal". I also got out into the garage this afternoon and hooked up the lower wiring, (engine) oil lines, and put the forks up in there. (sorry no pics) I feel like I'm not doing something right so I'll spend a few minutes reading the service manual tonight/tomorrow morning. Any idea how much weight the stock headlight mounting braces can support? My new headlights will weigh in the neighborhood of 7lbs...  | ||

Nillaice |

nice score on the lathe, i have the axle inside dimensions .....somewhere. found it! two are .875 ,and the others are .660, and .775. i'd recomend a 1/2 inch of aluminum to stick out. i made mine with 1/4 inch over hang, and the swingarm still made contact | ||

H2owerker |

I apparently forgot to take good pics of how the throttle, and idle cable went around the frame and through the "clamp" w/ the wire harness. If you've got some good pics of these areas, or have the time to go take some I'd love to see. Here's how they're routed now.   They seem to get pinched when I turn to the left lock, and I know that can't be right... Any help is appreciated!  | ||

Bads1 |

Ryan, Try loosening the Harness plastic clamp up. Then twist the throttle with the bars turned. I bet it won't bind. They updated that plastic piece for that very reason. Go get one from a dealer. Just ask for a 08 one. I think they updated in 06 if memory serves. Usually the binding you are getting is from that piece..... not much room in it. | ||

H2owerker |

Dana, I don't have any throttle to connect them to yet, and figured that it will be easier to route them w/o everything else in my way. I ordered new cables from American Sport Bike cause the molded tip on the original had busted, (probably the cause of the throttle stick I dealt w/ last year) and needed to be replaced. Adasoldier posted some great pics for me on buelletinboard and I think I'll get them in there tonight. I might spend enough time out there to get the handle bars on. | ||

H2owerker |

I wasn't really feeling like going out into the cold tonight, but I grabbed a couple beers and headed out anyway. Thanks to adasoldier on buelletinboard I knew how to route the cables and that didn't even take 1 beer to finish. So while I finished that brew I put the handle bars on along w/ the instrument housing/instruments, and adjusted the throttle cables. I figured that was enough for tonight, so I enjoyed a fine Edmund Fitzgerald Porter (Great Lakes Brewing Co.) and admired my work.   I called the body shop today. The tank(?), fly screen, fenders, and chin faring should be done this week. I also got a call from my friend at the Tool and Die shop...he's getting laid-off  and wont be able to make the custom headlight housings. and wont be able to make the custom headlight housings.  I'll have to find another way to get them done. I'll have to find another way to get them done. | ||

Bads1 |

Starting to look good Ryan. Looking forward to meeting you for the races. | ||

H2owerker |

I started polishing the wheels, and found that what I thought was just minor surface oxidation goes much deeper than anticipated. I did get one lip on the rear wheel finished tonight, and hope to get the other done tomorrow. I have gained much respect for the guys that polish car wheels. On another note. I'll be getting the parts from the body shop on Mon.  | ||

H2owerker |

And the guys that polish their frames are GODS... I finished the other side of the rear wheel and also did the larger lip on the front. So with out further ado. Here's how the finish looks... Before:   After:   I figure they look (basically) the same so pics of one wheel should suffice.  | ||

Bads1 |

Ryan, Looks great man. Looking forward to seeing it all wrapped up. | ||

Mm128 |

Your doing a GREAT job... Keep it up. MORE PICS!!! Matt. | ||

H2owerker |

"MORE PICS!!! "-Mm128 Wait. What? I'm not posting enough pics? lol I'm trying to only post significant progress...I have taken many more pictures though. It's great that many of the peeps here on badweb appreciate all the hard work I'm putting into this. Sometimes I wish I had more patience when I was searching for a bike. The PO must have neglected nearly everything cosmetic on this bike, and now I've spent an entire season repairing that stuff. | ||

Mm128 |

It all makes it that much more valuable to you in the end.... Also less of a chance you will sell it for dirt cheap knowing how much time and effort you have put into it. Matt | ||

H2owerker |

Ha! I'm afraid it's becoming invaluable, and I wont want to risk damaging it by riding. I could never ask what I feel I've got into to it if I decided to sell her. So I'm going to ride her like the tramp she was meant to be, or as hard as I can anyway. I got the parts today. They're beautiful !!! I've got to place my new Buell badges this week, and really get to work finishing the assembly so I can post some pics of the new color. Sorry, I want to keep that a secret for now. Even though I know it's been done at least once. (I found someones pics online after I dropped the parts at the body shop) Oh well. | ||

H2owerker |

ARGH! I used up about 3 feet of 12" wide 3M Scotchguard paint protective film last night trying to cover the fly screen. I thought I had a better plan tonight...till I tried to lift it up to stretch a wrinkle out. That's when the paint came off.  Back to the body shop to dump some more money. | ||

H2owerker |

Oh. On another (happier) note. I got the secondary drive pulley, idler pulley, and rear wheel pulley installed today. The 04+ belt conversion kit from American Sport Bike kicks a$$! Thanks AL! |