| Author | Message | ||

Fmaxwell |

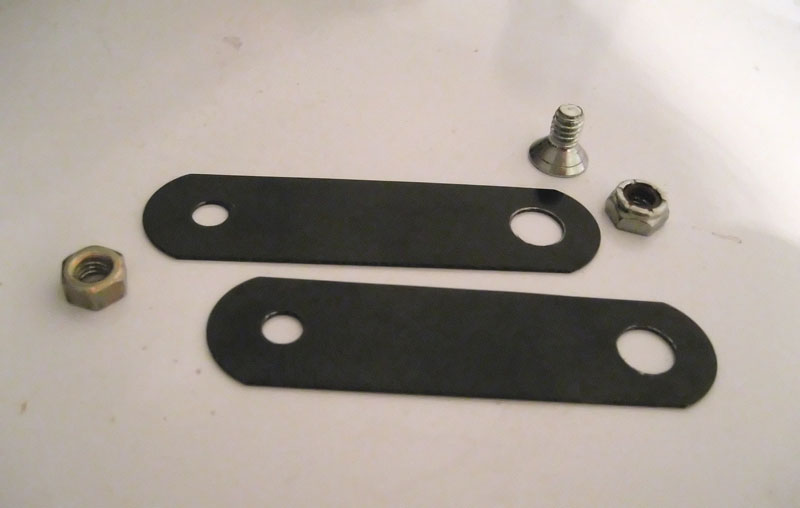

I noticed a raspy buzzing that occurred at 2100-2500rpm. Using a piece of aquarium air line tubing jammed in my ear, I probed around while varying the throttle (sitting still -- not riding!) until I located the sound: It was behind the flyscreen. Removing the flyscreen and revving the engine to 2100-2500rpm showed that the horn was jumping up and down by probably 3/8". A bit of research online showed that this was a known problem. Popular Mechanics tested the XB12S and wrote: "As the Lightning was approaching 4000 miles on the clock, it developed a rattle behind the bugscreen. All that long, hard thumping had hammered the horn bracket one too many times. We found it in two pieces. Wrapping the entire horn assembly in an old rag stopped the ruckus, and that's the only quality issue we've had." It's been mentioned in various posts and I'm betting that there are people who have heard the rattle/buzz and just haven't figured out what is causing it. Examining the factory mount revealed that it is just two, flat, thin pieces of steel sandwiched together. The horn is held on with a nut on the end of a stud. The other end is held in place with a flat-head screw going through an oversized hole. Here are the ugly factory components:  So you have this heavy pendulum (the horn), suspended at the end of springy steel. Who'd have guessed that it would bounce up and down violently at a certain frequency? (Okay, the average collie could have reasoned that out.) So I got some U-channel aluminum. It was labeled as edging for 5/8" plywood. I constructed the bracket shown below:  The bracket has two 1/4" holes in it at the same center-to-center spacing as the two dissimilar sized holes in the factory bracket. Rounded corners... It looked like there may have been an issue with a square-cut bracket hitting the flyscreen or the black foam inside of it when the bike was running. Since it's just aluminum, it was easy to round the corners to avoid this potential problem. I replaced the flat-head screw with a 1/4" x 20 tpi button-head screw that was 1/2" long. I used a washer under it to (spread the load and reduce vibration) and a nylon insert locking nut (taller than the factory nut). On the horn end, I got an M5 (I think) metric lock with nylon insert so that it can't vibrate loose. Putting the flyscreen back on, I put some anti-sieze thread lube on the stainless screws as stainless has a tendency to gall and was hinting that it might want to. It's almost always a good precaution with stainless. Total time to fabricate: Maybe 30 minutes. Result: Rock-solid. No more flapping horn. | ||

Tx05xb12s |

I managed to cram a Stebel Nautilus 139db airhorn in place of the stocker. There's no room for it to rattle. Plus it's loud enough to make your ears ring for a little while after giving her a blast. How about that? | ||

Xbullet |

i took mine off. | ||

Toona |

You mean your's wasn't broken? I replaced the broken straps with a piece of 1/8" x 3/4" flat stock aluminum.  | ||

Gentleman_jon |

Philip, I would love to see how you jammed the Stebel into the space formerly occupied by the stock horn. Any pix available? PS: my horn support broke too. I replaced it with a piece of steel plate from the hardware store that just fit, holes and all. I just had to cut it in half! | ||

Fmaxwell |

You mean your's wasn't broken? The only reason that it was not broken was because I replaced it at under 800 miles on the odometer. What a horrible design. Yours broke right where I expected that one would. Buell design mistakes: 1. Using two pieces of thin steel results in something much less stiff than had they used a single piece of steel that was the thickness of the two combined. 2. The flat-head screw with a non-chamfered edge on the bracket causes cracks to form. It acts as a wedge, trying to stretch the metal at the hole, tearing it in the process. 3. By not using a button screw or a washer to spread the load, major flex occurs at the edge of the hole (where yours shattered). 4. Steel rings like a bell; that's why they use it for musical instruments like xylophones and steel drums. It does not damp vibrations like aluminum does. 5. The primary vibration is in the X axis (up and down) and the bracket is parallel to the ground plane. Can you say "diving board"? 6. The horn has no locking nut, lock washer, or Loctite. Not even a flat washer. I replaced the broken straps with a piece of 1/8" x 3/4" flat stock aluminum. That had been my original intent, but I figured that the channel was just as light and stiffer. I was also afraid that I'd just end up moving the resonant frequency if I used flat stock -- and then have to deal with stress-fractured aluminum later. (Probably not, but I've found that I get burned every time I figure out how something could fail and then decide that it won't.) I hope that you have many happy, trouble-free years of honking with your horn. | ||

Toona |

I hope that you have many happy, trouble-free years of honking with your horn. So far, so good. I've got 7000 miles on the "new" bracket. I only fabbed it out of aluminum because I work with aluminum all day long and had some handy. I bought my bike used at 4700 miles and it was broken then. I probably wouldn't have heard the harmonic ring (before it breaking), but only found the broken bracket when the horn didn't work (no ground) when going for state inspection. | ||

Toona |

BTW, Fmaxwell, checking your profile, Welcome to the BadWeB! You'll find info on here (quickly) that would take forever (if ever) to find out somewhere else. | ||

Mikemax |

Mine just came loose causing the rattle... tightened it and used Loctite and it still doesn't buzz after over 10,000 miles. | ||

Tx05xb12s |

Jon: It would be a heck of a tight fit with the stock flyscreen. I managed to just get it to fit with a Uly flyscreen. The Uly screen bubbles out a little bit, giving you just enough room to get it in there. Otherwise, you can take the horns off the compressor and mount them in place of the stocker. The compressor can go in the airbox by running some high pressure hose to the horns. I had an old bag in a SUV move over into my lane one day and I gave her a good blast right outside her door. I though I was watching an Exorcist rerun when I saw how fast and how far she could twist her head around. Bet she had whiplash. And no I don't think I was being mean by scaring an old lady. It was either that or cave her door in with my boot. I thought I was being a gentleman.  |