| Author | Message | ||

T9r |

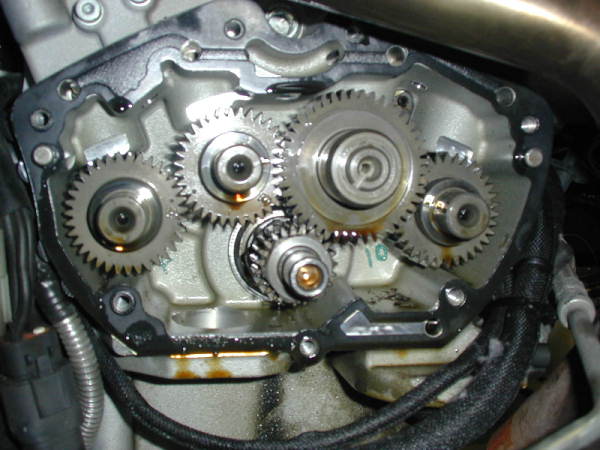

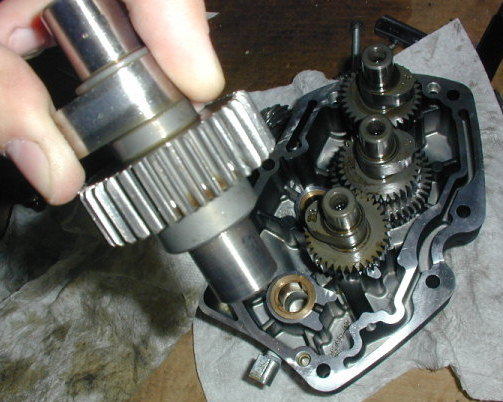

A 2003 XB9R with 15k miles on it. Mobile 1 synthetic thru it. I already removed the oil pump which was frozen up from the debris of the oil drive gear self destruction. Under the cover   The cover  The bike being taken apart   I choose the easy method of getting to the rear header bolts. No rotation of engine. Remove rear shock. Remove the noisey fan.  Clockwise goes the fan (looking at it from the rear of the bike) will allow it to rotate out. Took me some time to figure it out even with a manual.  (Message edited by t9r on July 17, 2006) | ||

Kootenay |

Ouch! Looks like my own 9R--hmmm, maybe this winter I'll have to look into installing the upgraded pump gear... | ||

Skully |

T9r, Why do you say this is a typical sight? Thanks, Keith | ||

Frequency |

Hmm this looks familar Thanks for the TPS reset  Bike runs sooo much better now Bike runs sooo much better now | ||

T9r |

Skully, I say typical because this is what they will typically look like when they fail. Look for pinion gear, oil pump drive gear or oil pump here on Badweb. http://www.badweatherbikers.com/buell/messages/3842/129393.html http://www.badweatherbikers.com/buell/messages/3842/14795.html You'll find that there is a flaw in the mesh up of the two gears. That is why now in 2006 Buell installed a new pinion gear, known as the high performance gear. Granted I have put 30k miles on two different Buells, an S2 and an S3 and no failures yet, but I'll be changing out the gear for sure now! I'd read about the failure before and I was warned. Frequency - Glad the TPS reset did your bike good. Are you surprised at how fast it takes to reset it? | ||

Blake |

Not sure the gear is at fault. Excessive runout on the shaft is a known culprit. I need to check mine since inadvertently downshifting to 2nd at 80 mph some time ago. | ||

T9r |

So if I replace the oil pump main gear and the pinion gear with the new one will I still have an excessive runout issue? | ||

Frequency |

Yea it was pretty fast, i took her out on the twisties last night and she rolled into and out of the corners much better | ||

Whodom |

So if I replace the oil pump main gear and the pinion gear with the new one will I still have an excessive runout issue? T9R, I don't think anyone ever conclusively identified a problem with the runout of the gear, although that is certainly possible. It seems that the main thing is that the new drive gear is made of more durable bronze so it doesn't wear like the original, maybe even if the alignment or runout is out of spec. | ||

Whodom |

So if I replace the oil pump main gear and the pinion gear with the new one will I still have an excessive runout issue? Blake, Who identified a problem with runout on the shaft? It certainly seems like that would cause the wear patterns we've seen, but I don't think anyone ever conclusively identified that as the root cause of the problem. It seems that the main thing is that the new drive gear is made of more durable bronze so it doesn't wear like the original, maybe even if the alignment or runout is out of spec. If you'll look through the old threads on the subject, you'll see where Whitebuell noted that the gears were improperly aligned on his bike (the driven gear on the oil pump was significantly below the centerline of the drive gear on the crankshaft). He machined the face of his oil pump which raised the oil pump driven gear and brought it into proper mesh. He also case hardened the drive gear (this was before the hipo gear was introduced) and this evidently corrected his problem. T9R, Glad to see your cam gears came through evidently unscathed. | ||

Odinbueller |

Is the valve train unloaded?!?! You are putting some serious strain on the crack side cam bushings if not! If you're going to do the repair on your own, follow the procedure to remove the rocker arms to unload the valve train, pull your cam gears & THOROUGHLY inspect them. Be sure to flush out your entire oiling system to ensure no debris gets into the rest of the engine. In fact, I'd highly recommend a top end tear down to see if there's any debris in the sump. It looks like the snap ring on the gear case side of the crankshaft failed, allowed the shaft & bearings to walk out, causing what I see there. Just now dealing with the same issue on an '06 XL883R with 209 miles on it! If there is a good Buell dealer close by, I'd take it to them to see if there's anything they could do on your behalf with the motor company. If there are many failures like this, then the motor company will want to know about them, warranty issue or not. Good luck! Chris | ||

Bake |

Any track miles on this engine? | ||

Sgthigg |

Did you have any symptoms.....ie knocks or weird vibrations...it might give some of us an idea of when it might be about to go out. | ||

T9r |

No track time on this bike. The first year I had it did mostly commuting with a long distance trip thrown in there once or twice. I'd wind it up a time or two but not bouncing over into the red. I've been getting more vibrations thru the handlebars recently, but I don't know if it was just me changing to my summer gloves. If that was the identifier, then it was a very small one. | ||

Dago |

I'm sorry to see this keeps happening. Mine shredded too, sending shrouds of metal through my entire system, thus destructing the motor (and a few other things) entirely. At least that's what some believe happened. There are other theories too. All I know is that there was a $h1t load of metal in the oil they showed me, the piston sleeves were gnarled out, and the drive gear teeth had been shaved down to where they were as sharp as knives. It happened in a CMRA certification mock "race" at the end of my 3rd/4th (?) track day on the XB with just under 12,000 miles on the clock. Fortunately, BMC covered everything under warranty and had the bike back to me within 7 days.  | ||

T9r |

Dago - so how did the oil get past the filter? It should of caught all those metal pieces. | ||

Dago |

I don't have a clue, T9r. I just ride the thing. But the mechanic went as far to say that he had to flush out the swing arm several times to be sure all of the metal shavings were out. | ||

T9r |

On every vehicle I've owned, cars/trucks and cycles, I've always found metal attached to the magnet on the oil pan plug. There is a certain amount of wear that goes on in an engine thru its life. Don't think this bike has any warranty on it. | ||

Blake |

T9R, Check the shaft runout then you can be sure one way or the other. Ditto what OdinBueller says about your cam bearings. Did you remove the rockerboxes before removing the gearcase cover? Whodom, I have heard the shaft runout issue confirmed by a number of experts in the industry. Dago, If the broken bits went into the return side of the oiling system, then they would end up in the oil reservoir/swingarm as your mechanic observed. Following that and the destruction of the oil pump drive gear, it seems likely that oil starvation may have caused the damage to your engine. Or the bypass function of the oil filter may have allowed metal bits access to the engine as well. Sounds to me like your oil pump drive gear hadn't entirely catastrophically failed though, not like T9R's has. Sounds like it was about to do so. The number of instances of catastrophic oil pump drive gear failure that I know of I can count on one hand. It certainly isn't "a typical sight." Given a little more time, it's probably about as many as the number of brand new R6's that will have burst into flames due to a typical low-side slide. Probably far less too than the number of Gold Wings whose frames cracked in half. If anyone has ever over-revved their engine through inadvertent or overly aggressive downshifting, I'd strongly suggest keeping an eye on the oil pump drive gear, and if you notice excessive wear, have the pinion shaft runout checked. Then if required, have the flywheel/shaft assembly re-trued. | ||

Dago |

"The number of instances of catastrophic oil pump drive gear failure that I know of I can count on one hand. It certainly isn't "a typical sight." Given a little more time, it's probably about as many as the number of brand new R6's that will have burst into flames due to a typical low-side slide. Probably far less too than the number of Gold Wings whose frames cracked in half." Geeze... you sure are defensive aren't ya, Blake? Lighten up. $h1t happens to all makes and models. | ||

Jcbikes |

How hard is it to replace the oil pump drive gear (my 2004 xb12s) with the newer (2006)gear? Is this something we all should be thinking of doing? I have 11,000 miles on bike so far with no problems and when i change the oil at every 1,500 miles, there is nothing on the drainplug magnet. | ||

T9r |

I'd say the job is relatively easy...well straight forward anyways, take that with a grain of salt. In a week of afternoon working I'd say the job could be totally completed. While the headers are off you might as well take them to get powder coated or ceramic coated along with the muffler. There are lots of parts to remove, just so you can move the header out of the way to get the cam cover off. A shop with lots of semi special tools helps (crows foot wrench, u-joint adapter, extentions of various lengths, torx sockets, a way to support the whole bike and a couple of jacks). One special cam gear locking tool is needed. Then to reinstall make sure you have all the seals and gaskets (2 exhaust gaskets, 1 cam cover gasket, 1 cam gear o-ring seal) I didn't think it would happen to me... so much for that thinking. | ||

T9r |

I want the part number for that NEW 2007 redesigned oil pump and the availability! | ||

Kootenay |

I thought I read somewhere here that you could just drop the oil pump, change the gear (the driven gear only, of course) and re-install. The drive gear would of course remain... | ||

T9r |

Something worth researching. | ||

Blake |

"$h1t happens to all makes and models." Agreed. Didn't mean to imply otherwise. Admittedly I am a bit sensitive to what appear to be exagerations/overgeneralizations akin to the title of this thread. | ||

T9r |

I've seen a hand full of eaten up drive gears, on here alone, which leads me think about the failure rate of this component. If there was no or little problem with them then why did Buell redesign the gear and make it standard on 2006 models? If there was no or very little problem with the oil pump why was it redesigned and made standard on 2007 models? Why has it happened mostly to XL motors and not so much the XB motor. I'm the engineer sitting on this side of the bike wondering how and why this happened and is it really that uncommon of a type of failure. Typically if this gear is going to fail, this is how it will fail. | ||

Blake |

It is a failure that has happened. It is not common. Over-revving the engine during an errant downshift is also probably not common, but it has happened. All kinds of wild and wierd stuff happens to high performance engines. I simply disagree with your title characterization that this is a typical failure. It isn't. It isn't common either. It is something to be aware of and check on at say every 20K miles. Pull the pump and look at the gear. Simple stuff. Buell improves product all the time. Doing so does not necessarily imply that the previous configuration was faulty. If the root cause of the excessive gear wear is due to excessive pinion shaft runout, then the new gear may not be much help. Did you remove your rockerboxes before pulling the gearcase cover? If not, you'll be needing to inspect and possibly rework the camshaft bearings on the case side. I agree, if one experiences an oil pump gear failure, it will resembly what you have found. And I sincerely appreciate very much your sharing the information and the great photos. Thanks for that. | ||

T9r |

Blake my friend. My title only states this as a "typical sight". It is a typical sight when the gear fails. Okay Pulled the rest of the gears out, 2 cams are shot. Any aftermarket cams I should go with for a tad added performance? Also the retaining ring was worn down. Is the retaining ring, attached to the bearing race, allowed to move outward on that crank shaft? | ||

T9r |

Yes, the engine is in service position. Unloaded the cams before they were pulled. It was not all that difficult, glad I had to do it anyways. (Message edited by t9r on July 18, 2006) | ||

Blake |

That's good to know.  Dont worry about me and my ranting. I'm easily confused by words sometimes and can latch onto an issue like a hungry pit bull.  | ||

Wazza |

Uhm, so you can access the rear header by removing fan and shock? is this then an option to consider for someone about to install a new set of pipes (like me) and who is also worried about the engine rotation procedure? Sounds alot easier option! | ||

T9r |

Wazza, You are correct, this is an alternate option to rotating the engine. Rotating the engine is easy to do, just a couple more components to disconnect. If you were just dealing with the header it is certainly a safe option. | ||

T9r |

After pulling the gears out I surveyed the damage. Retaining Ring chewed up:  Retaining Ring and bearing race allowed to slide out:  The gear:    Some damaged teeth on two cam gears:   Hanging around:  | ||

Diablobrian |

Looks like a good excuse to get some hotter "drop in" cams while you're in there. You know you wanted to anyway  Just looking on the bright side  |