| Author | Message | ||

Mrred7 |

So, last week I started to ride and I stalled while engaging 1st gear. I said, "What are you a rookie?" Well, it happened again a few stops later. Today I get on my bike and same thing three times in a row in my driveway. "What's your deal, Jason?" Well, I then noticed I have very little travel on my clutch lever. "Oh Jesus, help me to get where I am going today." Clutch weep? There is a little fluid coming out of the puck but not gushing, more like very slow leak. Ideas, fellas???  | ||

D_adams |

Sounds like you know what it is. Parts to fix it, $100. | ||

Jc1125r |

Yep, the clutch slave is wanting to retire. | ||

Mrred7 |

I just bled the clutch with new DOT 4 fluid. Feels normal. Is that because the weep is slowly allowing air into the system from the actuator cover plug, the actuator or the actuator o-rings? Is this what I need?: http://www.erikbuellracing.com/store/parts-accesso ries/clutch/ebr-clutch-actuator-cylinder-kit.html Also: do i need this too when I do it?: http://www.erikbuellracing.com/store/parts-accesso ries/clutch/clutch-release-tool.html I will need a new actuator cover plug too, right? | ||

Froggy |

Doing a bleed will buy you a little time, but not much. All you need is the actuator. The tool will make things easier but it can be done with normal wrenchs. The plug is reusable (Message edited by Froggy on August 24, 2016) | ||

Jc1125r |

Oberon also makes a replacement. This has a lifetime warranty. Here is a link to a sample http://www.ebay.com/itm/Oberon-Performance-Buell-1 125R-Clutch-Slave-Cylinder-CLU-1125-/321260885769 Here is a video of the repair. https://www.youtube.com/watch?v=NCEetGIc9ks | ||

Mog |

I got the clutch kit for the slave replacement and have found enclosed in a separate baggie two identical flat O rings with no instructions as to what or where they are applied. My guess is they are to replace the single worn out O ring on the sealing groove of the dome nut BUT that is a guess. Two flat O rings in one groove? Strange also that the groove on the slave is a very wide gap for the O ring while the large end has two O rings occupying the whole groove. Is that what others see as normal? Does anyone have experience with the new flat O rings (more like rubber washers).  | ||

Joe7bros |

There's a pic on the EBR website: http://www.erikbuellracing.net/store/models/1125cr /ebr-clutch-actuator-cylinder-kit.html | ||

Nuts4mc |

haven't seen the flat o-rings... WASG #1 the flat O-rings ( which may have a better tolerance on their outside dia.) have less "friction" when you assemble the Dome nut to the assembly...as there is a torque spec...and the old "O-ring" design may have induced add'l friction causing an error in the actual torque used to tighten the nut. WASG #2 - Double O-rings are usually used when one ring tends to "walk" in the grove ( the grove is called a "gland" in eng. terms)the 2nd O-ring acts as a "backing" to ensure the seal does not move (too much)..most backings I have seen are usually teflon...the double O-ring is a "simple" and cost effective solution to the problem. WASG#3 - the oversize gland or too small an oring was probably done to allow the small O-ring to "float" in the gland ( or they couldn't find a "stock oring size that had the correct cross section and ID and OD dimensions) ...as a second O-ring there along with the 2 bigger O-rings may have caused too much "friction" in the design and excessive lever pull would be required Don't forget to install the spring which forces the piston against the dome nut. HTH | ||

Nuts4mc |

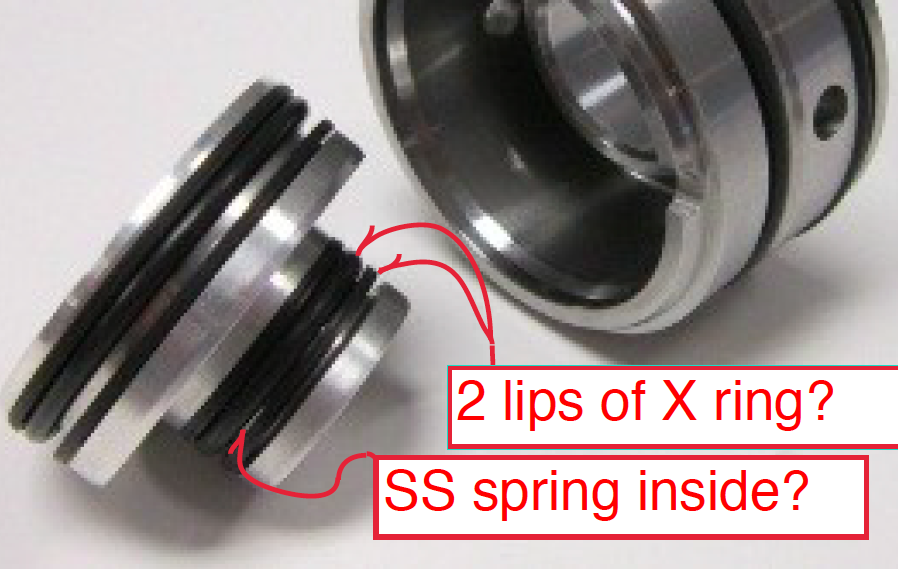

I can't tell by the pic ( too small , and I'm too old), but the EBR site looks like they use "X-Rings" not O-rings...I may be wrong ,but I believe Oberon uses X-rings as well. | ||

Mog |

Joe7bros - thanks, I had used that same picture on another similar post. After that I purchased the kit. Thanks much. Nuts4mc - The kit came from EBR and just hand labeled individual baggies of parts. I saw no X rings or spring loaded teflon or others in the baggies. I will pay strict attention to the springs and all parts going back together. Murphy's Law has been a huge factor in my life and we are most definitely on a first name basis. The last I want is some new noises in the engine, so I will ask all the questions I can of those who are much more knowledgable than I. My profound thanks to you all. I will follow up when reassembled.  | ||

Mog |

Nuts4mc, It does appear that EBR had used an X-ring in their kit picture but seems the problem of mistreatment by some mechanics of the more fragile spring may have prompted the use of a single O-ring? Go figure, huh? I blew up their picture for my eyesight (9 yrs older than you) and it seems an X.   | ||

Onetuford |

I'm guessing you got it figured out, but in case not see pic. Kit comes with 7 rings, two for outer sleeve (the biggest two), two for outward side of piston (middle sized) and three for small inboard side of piston, placed flat-round-flat. Re-use the spherical nut o-ring.  | ||

Mog |

Most interesting. Thank you. Definitely not what I got in the EBR kit. 2 large for the outer sleeve. 1 middle sized for the piston outside. 2 small flat rings for dome nut (?) It is back together and the test ride seemed ok. I will give it long & complete test Wed next week and see if it works well or leaks like a sieve.  | ||

Onetuford |

nah man that doesn't sound right. Your first pic shows the proper amount of rings for the piston. In that pic you have the two middle sized rings from the kit in the right spot, you just need to put the two flat on either side of the small round ring on the piston... | ||

Desert_bird |

I got the kit from EBR a while back. I don't think it had all those rubber washers either. (I can't recall what was missing now.) Nevertheless, I put it all together. It stopped the leaking, but the lever pull on the clutch is not all that light. Is there a way to confirm that the vacuum is working on the clutch? Without the proper washers could you stop the leak but not be getting the right amount of vacuum assist? | ||

Onetuford |

I don't have much baseline for reference as I'm pretty new to this whole vacuum assisted hydraulic clutch. I will say that my clutch before was soft and mushy, no "feel", and I would easily stall at lights and such. It is now stiffer than before the fix, yet still smoother than my buddies cable clutch on his newer Honda. I can't explain clutch "feel", but it most certainly feels different in a good way. | ||

Joe7bros |

When I did mine, I put it together as shipped, all the rings were in place. No leaks, good clutch feel. |