| Author | Message | ||

Baybuell |

Anyone experienced with the charging system swap please offer advice. Installed: EBR rotor Compufire VR Rewound stator (custom rewind) We wired everything up and the bike barely turns over and immediately drains the battery from over 12V to below 5v within 1 second. Something is obviously really wrong. We are really frustrated and are looking for any pointers. We are wondering if the ECM was hosed when the stator failed.... Thanks! | ||

Brumbear |

If there is no smoke or fire then thats a bad or low battery simple. The battery drains that fast theres gonna be smoke and fire | ||

Baybuell |

We thought that at first. Even with a new $250 lithium ion battery with loads of cranking amps first, then we tested with a car battery. Same result | ||

Dannybuell |

perhaps there is some resistance with a bad connection? recheck all of your grounds and the hot lines going to the starter? | ||

Zac4mac |

bad ground recheck all batt connections and grounds, you have paint between a ground and the frame most likely. or a loose connection. If you drain a 12 Ah battery in 1 second, something is carrying 43,000 Amps... lots of smoke and fire. | ||

Baybuell |

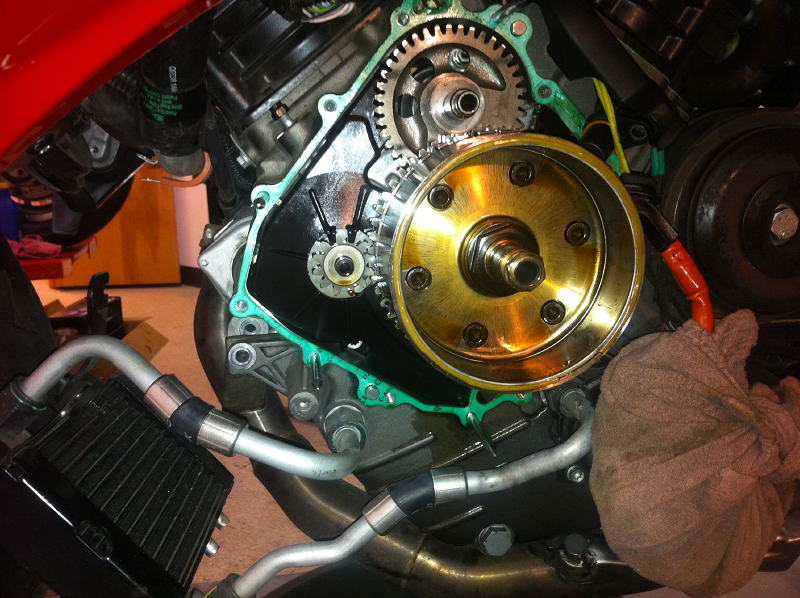

found the issue and reason even a car battery wouldn't turn the engine over. Lucky we didn't burn up the starter. The opening for the stator was made too small and was biting into the shaft when the engine was trying to turn over. We are wondering if we can just take a dremel tool open it up a little more to give clearance. oh yeah and it was HELL to get off!  (Message edited by BayBuell on March 11, 2013) | ||

Kevmean |

I'm a little confused as to why you think it is a problem with the custom rewind? The inner of the stator core is far bigger than the crankshaft diameter so if you are having issues with the extended piece of the crank rubbing it sounds like the casing wasn't on correctly or the end of the crank is running out of true. | ||

Kevmean |

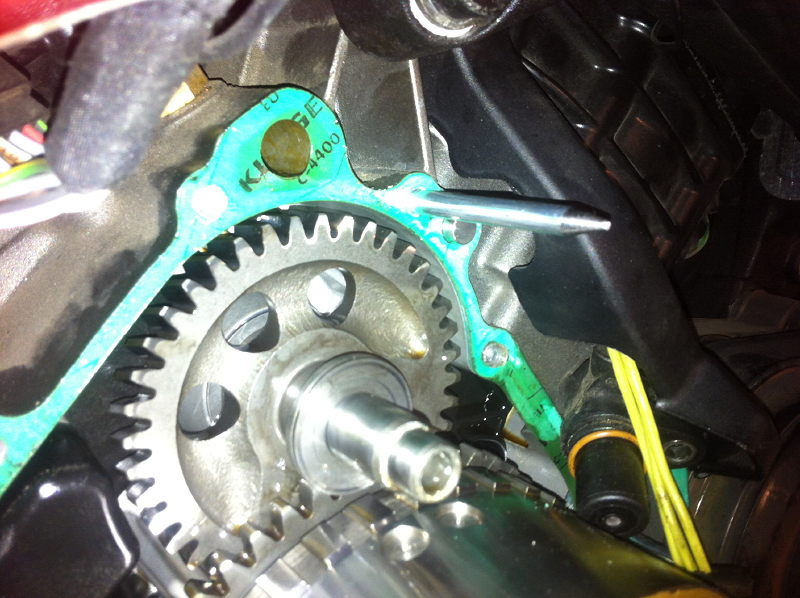

In fact looking at your photo compared with the first photo in this series of pics http://www.badweatherbikers.com/buell/messages/290 431/686391.html?1341805506 What is the white piece with what looks like green writing on it in the centre of your stator? Is it just the inside of the casting? (Message edited by kevmean on March 10, 2013) | ||

Zac4mac |

So, not a ground issue at all. Also not Custom Rewind's F-U either.  I've done this a couple of times now with no complications, your crankshaft's contact is with the cover, not the stator. The ignition cover is probably toast now. why tho? Is it even possible to put the cover on so it rubs? I used alignment pins I made to put the cover on - but there are two short pins there already.  Was there oil in the motor when you tried to start it? Is it possible to bend the crank??? Why are the lines drawn at the screw positions on the inside of the ignition cover? You need to check runout on the crank to see if it's bent, I can't see how you'd rub otherwise.  Really scratchin' my head here. Zack | ||

Kruizen |

Is that an 08 rotor with an 09 stator? | ||

Baybuell |

Ok, I’ll try to sum this up. The green writing is on the back of the crank case where we marked the old stator lead location vs. the new location where the stator was rewound. I think we were so exhausted trying to run down the problem, we miss took it for part of the stator. Definitely wasn’t a screw up from custom rewind, so I was off there. The end of the crank shaft when we measured it was off about 2 thousandths. We have no idea how it could be off. The bike hasn’t been touched since the stator was pulled and sent off. Our ONLY guess with the insanity of applying 300ft lbs of torque to the locking nut, that something was tweaked. The deep well socket never slipped off and its too thin to have rested anything on the end, so we are all still scratching our heads. (when I say “we” I’m talking about my dad who has built custom cars for over 30 yrs and my uncle who is a master machinist) We think that whatever was touching, the soft metal of the ignition cover kind of balled up and ceased rotation. We are sure we put the ignition cover on right to start with. We cleaned up the crank shaft end, machined 2 thousandths off of the inside of ignition cover, put everything back together and the bike fired up right away. Test rode and everything is running really well. We still are puzzled at crank shaft being 2 thousandths off. If we were to do the job all over again, wouldn’t touch it with a torque wrench. Would find an impact wrench that could do the job and call it a day. All I can say is… what a pain in the balls from a problem that should have never been put on the shoulder of consumers to start with. Especially from a bike with less than 6k on the odo. I was ready to give the thing away over the weekend. Thanks for all responses and offers to assist/troubleshoot. If anyone needs a crankshaft locking tool to borrow, I have one. | ||

Baybuell |

Other notes: Changed the oil to Motul 300V 4T 15W50 and the gears shift like butter. Best oil I've tried yet. Also, the new crankshaft locking tool would only screw up into the threaded area only one thread. after spending several hours going over and over the procedure to figure out what I was doing wrong, I took pictures of the locking tool with measurements of the pin diameter and length, and e-mailed it to the (seller). They responded with an apology that the pin was too long and their fabricator had screwed up. I had to grind the pin back to a total of 76mm and champher the end. Then screwed it into the hole and it locked in as expected to begin with. Who would have thought that a brand new tool made by well known Buell experts would have to be modified to actually do the job it was designed to do? | ||

Mortbike |

Hello Baybuell- Is the crank locking tool you had to shorten one that you bought from EBR just recently? I think they are made by Kent tools. I bought one from EBR just over a month ago and wonder if I have the same problem? thanks Mort | ||

Baybuell |

i responded in a private message. Didn't buy mine from EBR because they were out. | ||

Jsg4dfan |

I can give you a very good idea of what happened, because it happened to me. You probably put your cover on with it dry. Mine was squeeky-clean dry, and I found out the hard way that the clearance between the nose of the crank and that hole is close enough for some serious galling to take place. You're right - it is HELL to get the cover off. I sanded the nose of the crank with 200 then 400 grit paper, cleaned out the cover with a dremel tool, and cleaned everything well. Then, I oiled the hole generously when reinstalling, and all was well. That was about 1,000 miles ago, with no problems since. | ||

Drhodes1970 |

Is the gear on the back of the rotor? Mine was sent back without it and my mechanic installed it without knowing and I never looked at it. | ||

Kalif |

i thought it was only me who had such problem i could not start the bike after all rebuilds. even took off the starter and checked it,was working, a friend who knows a lot in electrical work told me that i have no problem,there is something wrong with mechanics,took off the cover spend a lot of time for that. the reason was no oil on stator cover.. To those who are going to rebuild their bikes rotor,stator etc, do not forget to oil the cover before installation!!! or you wont be able to start it!!! | ||

Rhard |

I used lubriplate engine assembly lube on the crank end and the clutch gears before reassembly. | ||

Buell0965 |

Baybuell Just wondering if you can help, like yourself i have fitted new stator and engine will no longer turn over. Drained oil to remove cover and cant get it to shift was wondering how you got yours off. | ||

Baybuell |

Buell0965- We had to gently pry if off using some thin bladed screwdrivers. gently so as not to crack the housing. Probably have the same problem we did, you might spray a little lubricant in before prying. The housing hole is more than likely "galled up" from the shaft touching it. You may need someone to turn the engine a little as you are prying out. Maybe not. | ||

Jsg4dfan |

I used composite pry tools, rocking pry motions, rubber mallets, and bad words. Lots and lots of very bad words... | ||

Zac4mac |

Never underestimate the power of bad-words and percussive maintenance. H-D=blowtorch+hammer | ||

Buell0965 |

Guys did you manage to split the cases apart with the engine in the bike, as its causing me real problems. | ||

Buell0965 |

Thanks for all the help took my bike out for its first ride today following stator rebuild. |