| Author |

Message |

Timebandit

| | Posted on Wednesday, May 30, 2012 - 12:18 am: |

|

http://www.badweatherbikers.com/cgibin/discus/show .cgi?tpc=290431&post=2222551#POST2222551 |

Timebandit

| | Posted on Wednesday, May 30, 2012 - 12:18 am: |

|

http://www.mcmaster.com/#2938T1 |

Tsnake

| | Posted on Wednesday, May 30, 2012 - 06:38 am: |

|

very good looking !! what about thickness? |

Zecca

| | Posted on Wednesday, May 30, 2012 - 09:00 am: |

|

flanged bearings looks nice...

you guys think I should put them in manufacturing??

I think it would be very difficult to locate exactly the right position

the cases of the EBR are entirely of Kevlar? or he just has kevlar in main parts of abrasion?

I have this case covers in hand.. do not have Kevlar the screws parts

mine have! I think it's improves the chewed up problem |

Zecca

| | Posted on Wednesday, May 30, 2012 - 09:01 am: |

|

this http://www.solobuell.com/buell-1125r/carbon-parts/ left-t-crankcase-protector-1125-carbon-lr |

Boogiman1981

| | Posted on Wednesday, May 30, 2012 - 11:13 am: |

|

Zecca the ones made for EBR by taylormade are kevlar and carbon. carbon for looks kevlar to resist teh abrasion. they are a dull finishone maybe two layers of carbon over what looks/feel likes 2-4 layers of kevlar all of which appears to be vacu-formed so is pretty light weight and very strong. |

Timebandit

| | Posted on Wednesday, May 30, 2012 - 02:00 pm: |

|

> "you guys think I should put them in manufacturing?? "

it could be tricky to properly locate them, but it shouldn't be all that difficult. someone has to drill holes in the right locations for the M6 bolts, and because you're drilling holes in the right location anyway, so you might as well drill holes that are a little larger to accept the flanged bearings. as an end user i would prefer that someone who makes these things would do this for me.

my EBR/taylormade stator cover came with holes drilled in it for the M6 bolts. I'm going to have to expand them a bit to make the flanged washers fit into it. i would prefer to buy a clutch cover that has flanged washers already fitted.

i would think that this would be easy enough to do if you made a jig to properly locate the holes. one person who does this repeatedly would be able to perfect the technique and produce a better result than 20 people who tried to do this only once.

(Message edited by timebandit on May 30, 2012) |

Zecca

| | Posted on Wednesday, May 30, 2012 - 03:22 pm: |

|

sure! but is hard to find this flanged bearings in brazil

I never actually saw

I will try! |

Zac4mac

| | Posted on Thursday, May 31, 2012 - 01:03 am: |

|

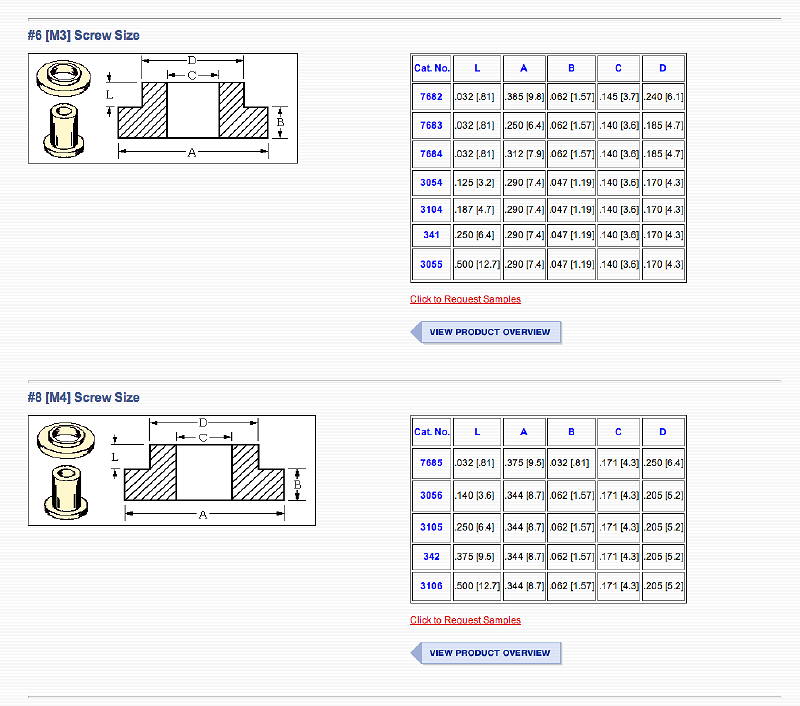

http://www.keyelco.com/products/specs/spec43.asp

|

Boogiman1981

| | Posted on Thursday, May 31, 2012 - 06:25 am: |

|

so Zecca i wonder if it'd be easier to source if one of us got you a fist full of the flanged bearings and sent them to you. i'd be willing to do that for you perhaps in trade or for a reduced cost of a set of the covers. |

Musclecargod

| | Posted on Thursday, May 31, 2012 - 11:36 am: |

|

Why the mottled finish without the carbon layers? Are you using kevlar mat? Woven kevlar may help if you have access to it. Also, some of the kevlar/carbon hybrid fabrics would look awesome in this application. A 2x2 twill blue/black weave for example

You can also get "black" fiberglass to get the look of carbon for less money. Depending on who you buy from kevlar comes in black as well.

Nice finish on that carbon! |

Zecca

| | Posted on Thursday, May 31, 2012 - 11:51 am: |

|

thickness 3~4mm

weight

|

Zecca

| | Posted on Tuesday, June 05, 2012 - 11:00 am: |

|

Update

opaque carbon version

http://www.badweatherbikers.com/buell/messages/21/ 682517.html?1338908378 |

Dannybuell

| | Posted on Tuesday, June 05, 2012 - 11:15 am: |

|

sweet |

Zac4mac

| | Posted on Friday, June 08, 2012 - 12:59 am: |

|

Z - gimme a week or two and I'm down for a pair of "opaque".

Nice work.

Z |