| Author |

Message |

Baf

| | Posted on Tuesday, July 03, 2012 - 10:10 pm: |

|

They did, but they were a little rough. The one pole that shorted out was all melted and charred up pretty well too. It was right up top where the wires from a different phase run between two poles - all 3 phases were shorted together at that point, so it must have gotten hella-hot on my ride home after it failed. I sanded the lamination on that one down a fair bit and wrapped it with a bit more tape - the other poles just had a thin layer. It helped with sliding the wire to pack the first layer of windings on as well.

I'll post up some pics in a little bit, but it seems to be successful so far. Right around 20 VAC from the stator at idle, 60 VAC at around 4k RPM. I rode around for a while, and never saw less than 13.6V. Had the bike idling for 20 minutes in the garage, and it was flickering between 13.6 and 13.7 - and that was with CT @ 200F, fans on high, high beams on, etc. This was on stock regulator, with upgrade harness bypassed. I'm going to install my CE-605 SB tomorrow.

Like I said, a few of the poles ended up kind of messy in winding. I did the whole stator in one afternoon (took me 15-20 minutes per pole, so a little over an hour per phase, and I took a 30-40 minute break between each phase), and getting tired towards the end, I started paying less attention to being neat. Fortunately, it doesn't seem to have affected performance at all. |

Baf

| | Posted on Tuesday, July 03, 2012 - 11:05 pm: |

|

http://dl.dropbox.com/u/11015924/2012-07-03%2018.3 6.20.jpg

Not pretty, but it does work, at least for now.  |

Baf

| | Posted on Wednesday, July 04, 2012 - 05:39 pm: |

|

Ugh, spent all morning mounting the CE-605 (bolted it underneath the tail section), buttoned everything back up, and got nothing. The new regulator must be faulty, at 4000 RPM it would only hit 13v briefly. I took it for a test ride and I was below 12v within a mile. Stator is fine - I pulled over and swapped back to the stock ducati regulator and was running 14v, so I guess I need to swap the CE-605 out.

I bought 50amp anderson connectors for the regulator hookup. I cut the 12v connector off the stock regulator, and put a connector on each side - the plan was to leave the stock regulator in and be able to swap back within minutes if need be. I just didn't expect to have to switch over immediately. Good thing I didn't just chop the wires off at the regulator. |

Mako

| | Posted on Wednesday, July 04, 2012 - 06:40 pm: |

|

thanks for the write up |

Hildstrom

| | Posted on Friday, July 06, 2012 - 09:24 am: |

|

Baf: If it works, it's pretty.  That sucks you got a bad CE-605 SB. What did you do rotor wise? EBR oil-cooling or DIY air-cooling? That sucks you got a bad CE-605 SB. What did you do rotor wise? EBR oil-cooling or DIY air-cooling? |

Baf

| | Posted on Friday, July 06, 2012 - 04:17 pm: |

|

EBR. I put that in ~400 miles before the stator crapped out.

I'm sure I'm not helping out the rewound stator much by doing this, but it's been running like a champ on the stock regulator w/o the upgrade harness. It's been hot here the past few days, and I've had several long strings of sitting in traffic. Any time I've checked, voltage has been no less than 13v, even after sitting for 10 minutes at a light with CT > 200F. Of course once I get the replacement CE-605, I'll put that in and (hopefully) be done with charging system issues. |

Baf

| | Posted on Wednesday, July 25, 2012 - 04:22 pm: |

|

Ugh, the new CE-605 worked great at first. 20 miles later, CEL and sys voltage error, under 12v @ battery. Pulled into the next parking lot I saw, swapped the connectors back over to the stock regulator, and I was back in business. Either I'm having bad luck on getting bad regulators, or something about my bike likes to eat them up.

If I start the bike with the CE-605 hooked up, it'll put power out for 5-10 seconds, then cut out. You can watch voltage drop from ~14v to 12.xv instantly, and also see the headlight get dimmer when it cuts out. |

Hildstrom

| | Posted on Thursday, July 26, 2012 - 12:20 pm: |

|

That's not cool. Could it be a bad connection? Did you solder or just crimp the connections? Hopefully it's something simple, quick, and cheap like that instead of a bad regulator. |

Baf

| | Posted on Friday, August 03, 2012 - 08:38 am: |

|

I crimped and soldered longer leads on the stator inputs for the regulator, and then brought them to a deutsch connector to plug into the stator plug. The DC side goes to an anderson connector. I cut the connector off the stock regulator and hooked that to an anderson connector (and put one on the stock as well, so I can switch back to it).

The connections seem fine, so I'm not sure what the issue is. |

Hildstrom

| | Posted on Friday, August 03, 2012 - 01:35 pm: |

|

Did you install the circuit breaker that came with the CE-605 SB kit? I left it out. |

Baf

| | Posted on Tuesday, August 07, 2012 - 10:13 pm: |

|

No, I didn't. I hooked the regulator in where the stock one hooks, no breaker or anything. |

Baf

| | Posted on Saturday, September 22, 2012 - 01:22 pm: |

|

My re-wound stator failed, due to the windings not being neat enough. What happened was one of the phases, where it crosses from engine-side to the outside of the stator to hook to the harness, was sticking out too far. The magnetic force eventually broke the epoxy free, and then the wiring started rubbing on the rotor. So, if anyone else re-winds, take care to get the windings neat. I just re-wound another one for my bike, and between the practice from doing it last time, and not trying to get it done in one day, I produced a much neater outcome, similar to Hildstrom's.

As far as my rotor, I hope it isn't too negatively effected. The magnets don't seem to have been damaged, but there is a small chunk of metal missing along with a bit of abrasion where the one wire was rubbing against the rotor.

Also, as a note on the CE-605, I'm pretty sure the reason this new one was not working properly was due to the stator only generating power on one phase. I'll be able to confirm this once I get the bike buttoned back up.

(Message edited by BAF on September 22, 2012) |

Hildstrom

| | Posted on Thursday, September 27, 2012 - 10:31 pm: |

|

Hang in there Baf. I was pretty bummed out when I had to disassemble it to fix that short to ground. It's well worth the effort and you'll be very happy once you get it all dialed in. |

Reepicheep

| | Posted on Friday, September 28, 2012 - 08:51 am: |

|

I guess the good news is that unless you broke the magnet into pieces, you didn't break the magnet. Gotta love that kind of simplicity. |

Baf

| | Posted on Sunday, September 30, 2012 - 01:23 am: |

|

Everything seems to be performing awesomely, mirroring Hildstrom's results closely. I'm taking a week long trip on this bike in a couple of weeks, so I suppose that will be the real test. Given the past few hundred miles of rock solid operation, I'm not anticipating any issues though. (*knock on wood*)

As far as the rotor, I'll keep an eye on it. Except for the one gouge in it, it's just some minor surface abrasion. I may fill/smooth that gouge out with some epoxy sometime; probably next time I have the motor apart (which hopefully won't be until my next valve check).

Big kudos to Hildstrom though; without his excellent documentation, I probably wouldn't have bothered to do a DIY rewind. |

Hildstrom

| | Posted on Monday, March 11, 2013 - 03:44 pm: |

|

Almost a year after doing this rotor modification and debating its effectiveness on BadWeB, an interested reader informed me of some overheating stator problems on the BMW F800GS, which has a parallel-twin Rotax motor. The official fix from BMW/Rotax is, get this, an air-cooling rotor design. Hopefully this lends a little credibility to my hair-brained hand-drilled idea. Notice the same 6 air holes spaced exactly half way between the 6 bolts. The main difference is that I placed my air-cooling holes at the rotor perimeter and BMW/Rotax chose the rotor flange. These flange holes are bigger, but I obviously thought perimeter holes would make better use of centrifugal force. Anyway, the original rotor construction looks remarkably similar to the 1125, which is no surprise. Both this air-cooling design and my hand-drilled one are easier to manufacture than the precision machined oil jet in EBR's rotor. Very interesting.

(Message edited by hildstrom on March 11, 2013) |

Reepicheep

| | Posted on Monday, March 11, 2013 - 04:20 pm: |

|

Thanks for sharing that new information. |

Hildstrom

| | Posted on Sunday, January 26, 2014 - 12:53 pm: |

|

I pulled my ignition cover after 5000 miles on the experimental setup. It's still working great. Notes and pictures are here:

http://hildstrom.com/projects/buellstator/index.ht ml#after5kmiles

(Message edited by hildstrom on January 26, 2014) |

Youk

| | Posted on Tuesday, February 25, 2014 - 05:00 pm: |

|

Guys, something to add to your write ups, if you like... I believe I found a source for the sleeves used when building the stators.

This stuff is rated to 500F / 260C.

Available from www.wirecare.com

Techflex FireFlex Silicone coated fiberglass.

(Incorrect information removed upon request of the poster)

(Message edited by reepicheep on February 27, 2014) |

Youk

| | Posted on Thursday, February 27, 2014 - 09:01 am: |

|

Please disregard my last post, I am unable to delete or edit it at this time. I will update this thread when I get my information straightened out. The sizes chosen above are incorrect. I will figure this out and re-post when I get the information straightened out. |

Youk

| | Posted on Thursday, February 27, 2014 - 02:49 pm: |

|

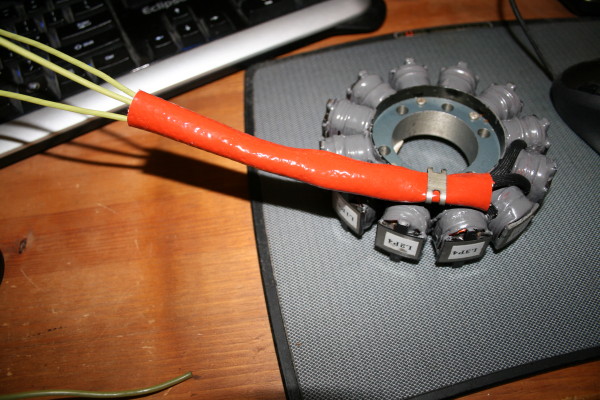

I wasn't crazy about using rescue tape to insulate my stator's connections. It seems too bulky to me. Here is what I decided to go with. There are three different sleeves used in the construction of the stator. I'll refer to them as outer, middle, and inner. Tech flex makes several different sleeve products that are available from www.wirecare.com in small quantities. Here are the products I decided to use and why:

Outer Sleeve:

3/8" FireFlex Silicon Coated Fiberglass (Red) Part# FIN0.38RD $23.95 for 5 feet. Good to 500 F Oil has no effect on it.

Middle Sleeve:

8 Gauge Insultherm Tru-Fit Fiberglass Sleeve (Black) Part# FGLG.08BK $3.88 for 10 feet. Good to 464 F Oil has no effect on it.

Should note original had rubber coating. Tech flex offers rubber coating on some products, but not in the size we need. I see no reason it matters, we are simply trying to protect and insulate the soldered joint, The outer sleeve is coated with silicon.

Inner Sleeve:

12 Gauge Insultherm Tru-Fit Fiberglass Sleeve (Natural) Part# FGLG.12NT $2.97 for 10 feet. Good to 464 F Oil has no effect on it.

Shipping was $8.35 Total $39.15 I will have enough for more than 7 stators. If anyone is interested in buying the surplus, feel free to contact me. I'll post pictures when complete. |

Pwillikers

| | Posted on Thursday, March 06, 2014 - 01:27 pm: |

|

Please do post pictures of your progress on your rewind and use of the sleeves. |

Youk

| | Posted on Sunday, March 30, 2014 - 07:34 pm: |

|

Guys,

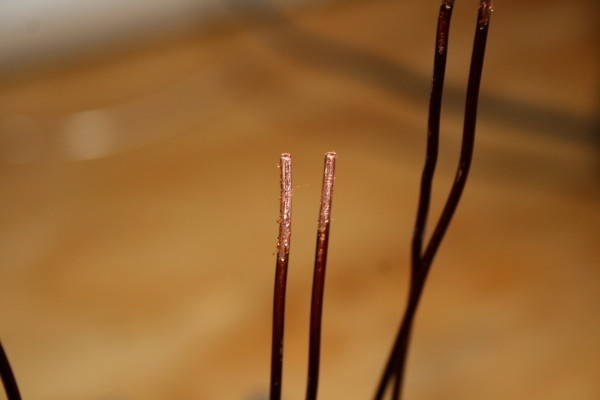

I finally got around to finishing my stator, sorry for the delay. In addition to posting pictures of the sleeves I used, I want to point out an mistake I made, in hopes I can prevent someone else from doing the same. This first picture shows the inner sleeve referenced in my previous post. It also shows the mistake I made. Each pair of wires should have been routed from cover side to engine side one pole clockwise from where I did it. This is very important, because, as you may have noticed, the alternator cover was designed to have the wires routed a specific way. The worst part of it is, I knew this ahead of time, had made notes of it, and thought I knew exactly how it should be done. The problem for me is that this can't easily be fixed. I chose to use JB weld, as Hildstrom did. Since it is cured, I doubt the wires can be removed without causing damage to the insulation. In any case I am not willing to risk it at this point. I will point out how I decided to deal with the issue as I go though the rest of my pictures.

The next picture shows a close up of my solid copper. I found it easiest to strip away the insulative coating with a knife. No heat necesssary.

The next two pictures show the middle sleeve. One thing to note, this sleeve material is more rigid than I expected. It is really cool, as you can make it expand by pushing the ends together, and shrink by pulling the ends apart. I was very impressed with this stuff, I will be using it for future projects.

The next two pictures show the outer sleeve.

Notice how I routed the wires on the right side. Fortunately for me I was able to route the wires in a valley on the pole marked L2P1. This is important because there is an aluminum rib on the cover under this position. I am just about flush with the plastic ring, and best I could measure with my calipers, I have about 3/16 of an inch clearance. I plan to coat the aluminum rib with high temp silicon before I install the stator.

Thanks for all or your guys help with this project. I hope this helps someone else... |

Hildstrom

| | Posted on Monday, March 31, 2014 - 12:55 pm: |

|

Very cool! Nice job and thanks for sharing. What are you doing as far as rotor and regulator? |

Youk

| | Posted on Monday, March 31, 2014 - 01:20 pm: |

|

I'm using the CE-605 SB Regulator, It will be mounted behind the license Plate. I'll post pictures on the appropriate thread when I get that done. (Hopefully next weekend.) I'm using the EBR machined rotor. |

|