| Author | Message | ||

Tbowdre |

anyone have pics of the oil orifice? dimensions, measurements? I have a couple brand spanking new drill bits just itching to make a hole EBR will definitely do this service for you, at a minimal charge... detail should be on EBR's web site next week. thanks for considering, todd | ||

Timebandit |

The modified rotor receives its oil feed directly from the crankshaft and a high degree of precision is required to accurately locate the pilot jet hole. The modification is performed at EBR using Electrical Discharge Machining. Because of the level of precision that is involved, this is probably not something you would want to tackle at home with a drill press. | ||

Timebandit |

| ||

Timebandit |

| ||

Avc8130 |

EDM? Really? They must plunge as it doesn't appear there is space/angle to run a wire through. Not to mention, if you wire EDM you need to drill a hole to pass the wire through. Pretty expensive. Does the large hole exist in the rotor already, where the "tooth" is "missing"? Do you have any more pics? Machining internal features like this is quite complex, but not impossible. Does EBR offer this service without the $900 stator kit? ac (Message edited by avc8130 on January 15, 2012) | ||

Timebandit |

Uh oh -- I hope I didn't give away any trade secret by saying that.  I'm not a machinist, so I can't speak to the method of EDM'ing, but I know that the rotors are EDM'd to make the oil jet pilot hole. You're right -- EDM is very expensive, in terms of machine cost, time, and labor involved for set-up. Asking someone at EBR to do custom work for guys like you and me requires pulling an engineer off the job he's working on and diverting his attention to servicing our needs. That's a lot to ask. These guys are busy. Asking EBR to fix BMC's legacy problems in a way that goes beyond what H-D is willing to do really does place an undeserved burden on the EBR staff. EBR is an independent racing company, and I have to give them kudos for being willing to even listen to the problems that street riders are having with BMC legacy products. It's really not their responsibility to fix the former parent company's problems -- especially if it involves taking measures that the former parent company isn't willing to take, and doing it at a price that undercuts the cost of shopping at P&A. These guys really are going out of their way to try to help, and they're getting almost nothing in return for doing it. My personal take on this is that EBR's $900 stator/rotor kit is a underpriced. Compared to shopping at P&A it's a STEAL even without the oil jet mod. The replacement kit should be priced higher than it is, and the modded replacement kit should be priced higher still. Remember: H-D charges a LOT more for the unmodified replacement parts. EBR is taking the H-D parts, doing work on them that costs a significant amount of time and money, and is selling the finalized product for LESS than H-D charges for the unmodified parts. That's a great deal for their customers, but not so great a deal for EBR. It eats up their resources and doesn't provide much ROI for them. I think they should be charging more for the kit than they are already charging. But that's just my opinion. Suffice it to say that if/when EBR announces any sort of custom machining service, nobody should bat an eye when they hear the price. As far as photos/specs go, I didn't take those photos. Those photos are the ones that briefly appeared on the EBR site and then disappeared. I won't post any other photos, or provide any additional descriptions beyond what EBR is willing to disclose because I don't think it's fair for anyone other than EBR to post photos or blueprints of EBR's intellectual property on the web without their permission. Doing that might facilitate a third party's appropriation of their intellectual property. If anyone deserves to make money on the service, it's the guys who came up with the idea. Will they offer the service without the $900 stator kit? As a coincidence, this thread comes along right after I spent late Friday afternoon on the phone with the lead engineer for the 1125 motor and the engineer who is in charge of the EDM project. I can't speak for them to answer your question. But everyone on this forum knows that if/when EBR decides to offer the service that you ask about, they're going to be deluged with calls, and servicing customer requests would result in a huge time expenditure for them. They're REALLY busy right now. I was surprised to see Tbowdre's post that the service would be added to the web site next week. | ||

Avc8130 |

EDM is an expensive process, but like most machining, if you set up to do the same operation a few times the cost goes down. I highly doubt EBR is selling the stator kit at a loss. They probably sourced the parts when they sourced their motors so they got a qty discount and are able to pass that along through to customers looking to make the change on existing bikes. I asked if they offered the modified rotors separately because I am one of those folks who enjoys the larger charging capacity. Switching to their complete setup is not ideal for me. $900 for a stator/rotor setup may seem cheap when you compare to HD, but it is right in line for the aftermarket. I am sure EBR chose the number for a reason. ac | ||

Avc8130 |

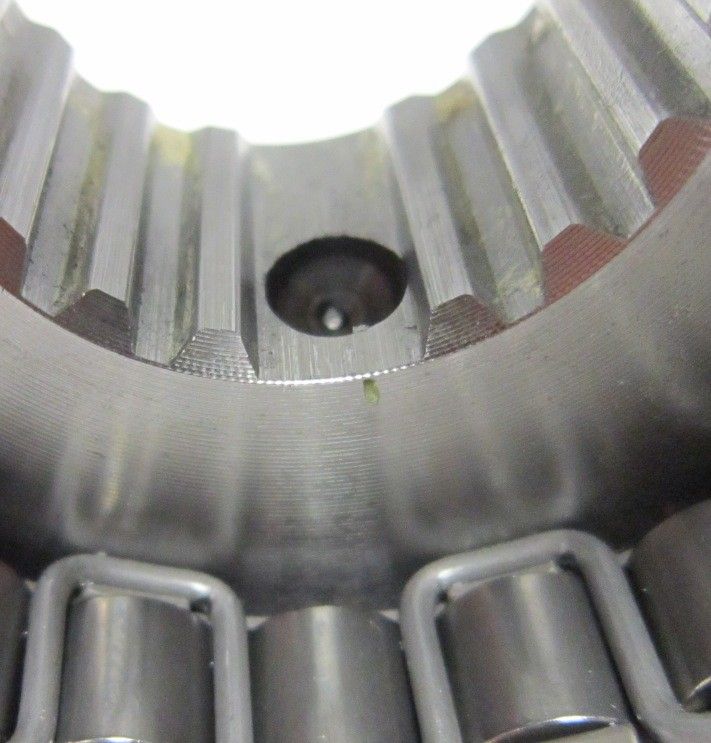

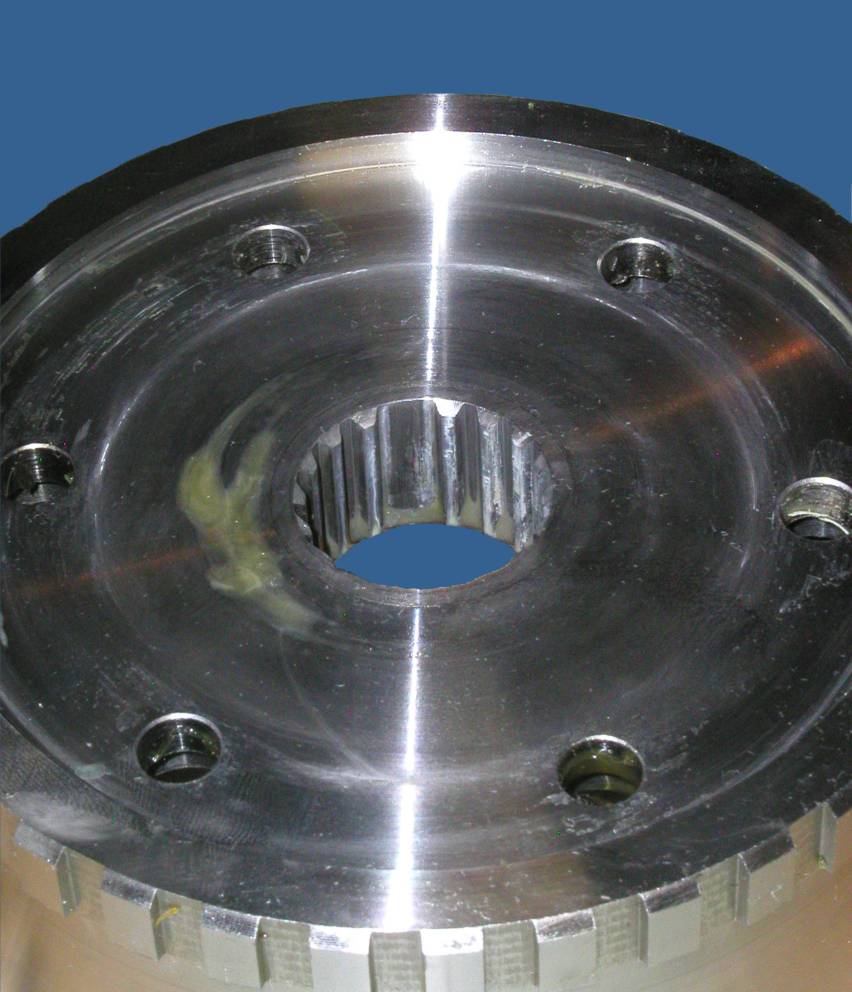

Time, Looking at those pics more, I think this is how it is machined: 1. Wire EDM tooth away. (This could be done a mill also, but you said the mod is EDM-ed, so I assume this is where they use the EDM). 2. Fixture at an angle to allow tool clearance. Mill/drill counterbore/sink and oil jet hole on a mill. If we had to do this at work, we would build a fixture if we were doing a bunch...if not, I would just clamp in the 5-axis and let the mill do the work. ac | ||

Timebandit |

EDM is an expensive process, but like most machining, if you set up to do the same operation a few times the cost goes down. The problem is that to make repetitive operations cost effective requires capital expense. You need a dedicated machine if you're going to do the process in large volume. Or if you have to share a machine for multiple tasks, then you need to do a large enough run to make the set-up worthwhile. It's not cost effective do do these things in onesy-twosy runs every time the phone rings, and doing them in volume (like a rotor exchange service) requires an investment in parts inventory. So there's a capital expenditure required. Good business practice requires a reasonable ROI. I highly doubt EBR is selling the stator kit at a loss. I'm not accusing them of operating at a loss, I'm just saying that they shouldn't feel obligated to operate at an insignificant profit today to correct problems from the past. The fact that their prices are so reasonable shows us that EBR cares about people who bought 1125 motorcycles from BMC. I have already told them that their EDM price was very fair if not too cheap and needed to be higher. I know, that's not what people here want to hear, but I want to see EBR make a profit and stay in business. | ||

Black |

I think that we get into dangerous territory by implying that EBR is competing with Harley to fix Buell problems That is doing everybody a disservice. I can just as easily buy an 08 charging system from Harley. I might want an EBR charging system one of these days....I don't particularly appreciate anybody poisoning the well for me to keep me from racing parts when I need them. Just sayin'. | ||

Timebandit |

I don't think anyone here has ever said that EBR is competing with Harley to fix Buell's problems. What I actually said was that it would be to place an unfair burden on EBR to expect them to assume those responsibilities. With that in mind, nobody here is missing out on the fact that EBR is offering a variety of race-only parts/services to race teams that end users of BMC products have always been interested in buying and mis-using in non-race applications. I guess I'm missing out in understanding how this is poisoning the well for anyone. | ||

Avc8130 |

All I see is a modified rotor that might be very beneficial to those with 09 charging systems who enjoy the increased output. I'm tempted to pull my rotor just to look at the crank and rotor...but the special tools and gaskets are holding me back. ac | ||

Froggy |

What I think Black was trying to say is that he doesn't want anyone to accidentally ruin something good. There is a fine line of what Erik and the gang can and can't do regarding our bikes due to various agreements regarding licensing and similar. If there was something that would get Harley enough leverage to shut down/sue EBR, Erik wouldn't touch it with a 3 meter pole. (Message edited by Froggy on January 15, 2012) | ||

Black |

Thanks Froggy, Exactly. | ||

Timebandit |

I don't think that it's realistic to think that EBR has to worry about H-D coming after them for lending a helping hand in making inconvenient problems go away. Think about the big picture. Harley has already washed it's hands of the situation. They're out of the warranty period now, you as customers don't represent a liability to them any more. Now all that the motor company is required to do by law is to maintain parts inventory until the statutory clock runs out for each model year. Then P&A can forget about stocking expensive/unprofitable parts and completely wash their hands of BMC, all of us, and all of our demands. To the extent that a product from the aftermarket solves a problem by diverting angry customers away from them, it's going to be welcomed. H-D is looking forward to the day when the phone will stop ringing. As far as licensing agreements go, Harley gains a revenue stream only as long as it's licensees remain in business. Drive them out of business and there goes your revenue stream. Harley has no incentive to drive EBR out of business. Realistically speaking, Harley-Davidson is NOT the bad guy. The bad guy is the Economy. The biggest threat that we face as Buell owners is that EBR is a small start-up company that is trying to remain viable as an economic concern during a hostile period in our economy. The biggest threat to small start ups is inadequate capitalization, and inadequate staying power to avoid financial collapse during tough economic times. If you want to make sure that EBR will be there for you in the future, you should be patronizing the business right now. That's what I'm doing. | ||

Timebandit |

Special tools? Turns out you don't need ANY. 1. You can pull the oil cooler lines with picks. 2. You can use M6 bolts with the heads cut off as alignment dowels so you don't fight the magnet when removing the stator/cover. I did it without them. 3. All you need is a 6mm (1/4") diameter hardened steel shaft to lock the crank. It doesn't have to be threaded if you've got a helper (or some duct tape) to hold it in place when you use a 1/2" air gun to take off the rotor nut. I guarantee that you've got something suitable in your tool box. 4. I didn't need the rotor removal tool. 5. You don't need to worry about the gasket unless you muss it up. It's a re-use item. 6. You MUST buy a new rotor nut. That's the only thing that will be holding you back. The whole project was a lot easier than I expected it to be. The book makes it sound a lot harder than it really is. Just be sure to disconnect the battery before you get started. | ||

Duphuckincati |

Why the "must" on the rotor nut? Due to ordering the wrong new nut and not wanting to wait for a proper new one, I used the original with a full load of the proper loctite and it was torqued to 300 lbs, hence my question/concern. | ||

Timebandit |

I'm not the expert, so take this all with a grain of salt. The rotor nut procedure changed a bit between 2009, 2010, and now. I have all the manuals. The manuals differ a lot between 2009 and 2010. Some of the things that we talked about were errors/misprints that I had found in the H-D manuals. In the 2009 manual (Sec 7.10 p 7-18) you're told to clean the threads of the crank nut by turning it back and forth with the breaker bar. This helps to get rid of the Loctite 646 (green). Back then the torque spec was 207-214 ft-lb. In the 2010 manual (Sec 3.11 p 3-76) the procedure was updated. You're told to clean the threads of the crank nut by turning it back and forth with a breaker bar, and to then use brake cleaner to clean the Loctite 272 (red) off of the threads. In addition, you're told to use brake cleaner to clean the red loctite off of the crank stud and the rotor nut. Back then the spec was to tighten the rotor nut to 210 ft-lb, back off 270*, and then tighten to 295 ft-lb. I remember your thread where it was discussed that the current torque spec is 300 ft-lb., which seems to match what's in the 2010 service manual. I spoke to EBR on Friday afternoon, and I specifically asked them about cleaning/re-using the "stator nut" vs. replacing it with a new one. I was told not to re-use the old nut and that I "must" use the new one. Must. Their words. They couldn't explain why the "parent company" put some of the things in the manuals that are in there. EBR doesn't re-use "stator nuts." Probably not worth their time. They just replace them. I had a lot of ground to cover, so I didn't linger to long on any specific point. I just ran through my list of questions as quickly as I could. We talked about a lot of different things and didn't spend much time on the rotor. Could the reason to use a new one be because the old rotor nut had 363 on it? (green). Could it be because some people couldn't be trusted to adequately clean the nut with BraKleen? Could it just be because their time is valuable and they have lots of clean nuts to work with? I was told that they have had problems with "stator nuts" coming loose in the field under sustained high-RPM conditions. Yikes! That's an exact description of my riding style (bars always buzzing), so I just took their advice as gospel. If you adequately cleaned the nut and crank stud, used red loctite, and used the 300 ft-lb torque spec, then I think you'll be OK. Just be aware that if you ever hear the clatter coming from the rotor area, you should shut the bike down and call for a tow. I wouldn't try riding it home as the results of a loose nut could be wicked. If you're really worried, just open it up again and use the new nut. | ||

Duphuckincati |

Thanks for the info. I'm going with the fact that I did the cleaning etc very well and am not doing track day type sustained high rpm, and I really don't want to bother the eighteen-wheeler repair guy for a third time to borrow his $1500 600ftlb torque wrench. But be assured I'll keep an ear tuned for clatter. | ||

Timebandit |

glad it was helpful. when it comes to dealing with that nut, the EBR guys told me that they use air. that makes sense. those things can produce lots of torque, and it's not like you're going to damage the crank nut by over torquing it. it also explains why some of their fasteners are such a bitch to get off. | ||

Avc8130 |

Time, They use air for installing it too? Do they set final torque by hand? ac | ||

Timebandit |

didn't ask. sorry. | ||

Bextreme04 |

i would assume they impact it on and then just check to make sure it is AT LEAST 300 lb-ft with the torque wrench  | ||

Oldog |

I would not use an impact on a rotor unless it is rivited and not glued then I would still not to avoid damaging the magnets the older ( hd powered buells ) had warnings about doing that damaging the rotor All you need is a 6mm (1/4") diameter hardened steel shaft to lock the crank. It doesn't have to be threaded if you've got a helper (or some duct tape) to hold it in place when you use a 1/2" air gun to take off the rotor nut. any issues with the threads in the hole that the rod presses on ( the aluminum threads ) when you apply 300 foot pounds of torque, I would worry about the threads getting mashed.. } (Message edited by oldog on January 18, 2012) | ||

Timebandit |

Does the large hole exist in the rotor already, where the "tooth" is "missing"? sorry, missed that question. nope. it has to be added as part of the mod. | ||

Duphuckincati |

But the hole is already in the proper spot of the crankshaft oddly enough. Wonder why that is...? | ||

Timebandit |

But the hole is already in the proper spot of the crankshaft oddly enough. Wonder why that is...? I wonder if that's a dirty little secret that's being protected by non-disclosure agreements. It doesn't take a rocket scientist to look at the crankshaft stud and realize that the plan to implement oil cooling for the stator existed when the crankshaft was made. What you need to be asking is this: Why would someone decide not to connect an existing oil cooling orifice in the shaft to a similar oil cooling orifice in the rotor when the bikes went into production? The answer has to be manufacturing cost. This modification requires complex machining that could have easily added a couple hundred dollars to the cost of the bike. To a manufacturer, that kind of additional cost per unit is HUGE. (Message edited by timebandit on January 20, 2012) | ||

Froggy |

If you knew even half of the things that never made it into production for one reason or another, you too would want to decapitate some HD execs  | ||

Timebandit |

any issues with the threads in the hole that the rod presses on ( the aluminum threads ) when you apply 300 foot pounds of torque, I would worry about the threads getting mashed.. yes, you need to protect the threads. there are a number of ways that you can do this. one fellow drilled out an M12 bolt to protect the threads while allowing the rod to pass through. another option is to just use a hardened rod that already has a centering handle attached to it. necessity is the mother of invention.  | ||

Timebandit |

2009 Rotor, backside. Sprag clutch removed. Note that oil jet pilot hole is absent.  |