| Author | Message | ||

Timebandit |

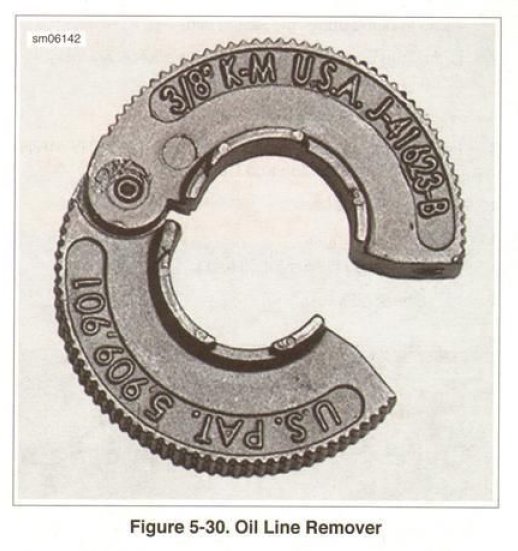

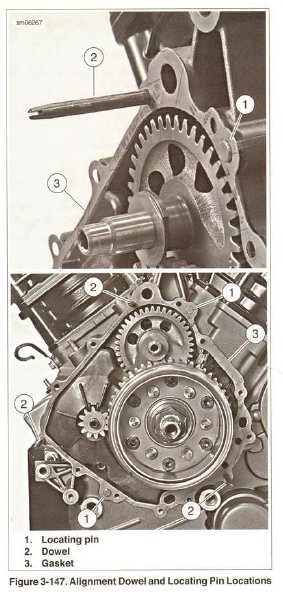

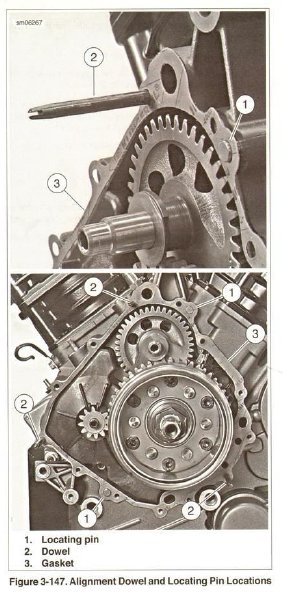

Rotor Swap Tool Checklist - Part 1 I've got some questions about the specialized tools required for performing an exchange of the charging system rotor. 1. Oil Line Removal Tool. HD-46503 / Kent Moore J-41623. According to the pics in the service manual, this tool bears a Kent-Moore part number of J-41623. According to the imprint of the tool in the pic, it's for 3/8” line fittings. See Pic.  A problem is that the fitting on the bike looks like it's a 1/2” fitting. So I thought I'd ask if anyone can confirm whether the 3/8” tool or the 1/2” tool are right for the job. I seem to remember reading on this site that somebody ordered the tool using the Kent-Moore part number in the picture, and it wouldn't fit the bike. It seems that there's some disinformation in the repair manual. Can anyone confirm if the HD-46503 is sized for 1/2” lines, which would mean that the Kent-Moore 3/8” tool pictured in the manual is a photo of the wrong tool? (BTW, I know that you don't have to have this tool if you're good at dealing with spring clips.) 2. HD-46503 Price. Does anyone know what the tool costs through HD parts? The Kent-Moore tool retails for about $75 (gasp!), but I've seen the HD part number in catalogs for 35 Euros. Haven't been able to find the price in dollars. 3. V-Rod Cover Alignment Dowels. HD-45340. It looks like the 1125 uses the same alignment dowels that are used for installation/removal of the rotor cover on the V-Rod.  Although the V-Rod only uses two dowels, it looks like 3 dowels are required for the 1125, so I'd have to buy two kits.  I haven't been able to find price/availability of HD-45340 in US dollars. Does anyone have a price? 4. Alternatively, I've thought about DIY by threading some steel rod. Can anyone tell me the thread size for those fasteners? I found part numbers in the parts manual, but the parts manual never gives any info on fastener sizes. | ||

Timebandit |

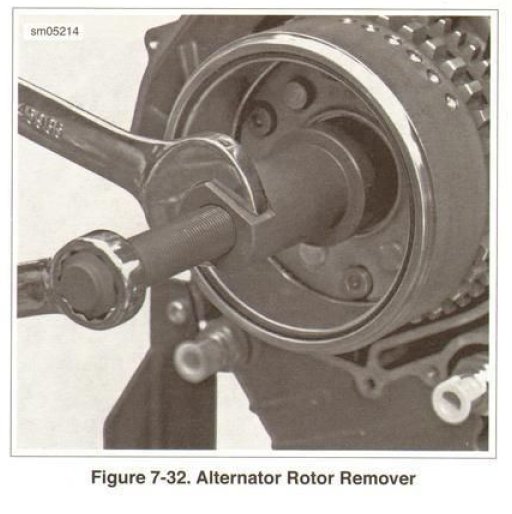

Part 2 5. Crankshaft Locking Tool. B-48858-A. $59.09 from EBR. Just wondering if anyone could put a caliper on it and tell me the diameter of the hardened steel shaft, the shaft length, and the thread size for the hook-up. I'm thinking about DIY for this part. 6. Alternator Rotor Removal Tool. B-48857.  Looking for price/availability in US dollars. I'd also like to ask if anyone who has actually pulled a rotor has actually needed this tool. Seems that some people have gotten by without it. Thanks. | ||

Timebandit |

Made a call to EBR and got some quick answers. Those guys rock. 1. they just use picks instead of using the line removal tool. 2. the cover bolts are M6. you can get the cover on/off if you're careful without the alignment dowels. I need alignment dowels I'll just cut the heads off of some M6 bolts. 3. you should be able to get by without the rotor pulling tool. they said the rotors come off easily once the bolt is off. 4. You've got to buy a new rotor bolt. don't re-use the old one. 5. I'm ordering the crank locking device from EBR. | ||

Dannybuell |

FROGGY - This should be a sticky | ||

Froggy |

The only thing sticky around here is my keyboard. | ||

Xtreme6669 |

And the Pilot Powers your running... | ||

Nillaice |

just buy/beg/borrow or steal the locking tool. the engine locking tool is hardened (as you know) for a reason. the first ones they made were not, and i don't have to prove it to my self that they need to be hardened by breaking it off in my crank shaft. get a new rotor nut from EBR while you're at it. and FYI; i took off the oil lines with a screwdriver. i just pulled the wire clip off the coupler, and then put it back in the slots so i wouldn't loose them. NO TOOL REQUIERD | ||

Steve_a |

And make sure you retorque a NEW rotor nut to the specified torque. It got raised after the 2008s came out for a reason. And if you happen to be running a chain drive kit, be doubly sure you hit the recommended torque, even if it takes a pipe over the end of your torque wrench, and absolutely do use the specified thread locking compound in either case. | ||

Zoolander |

Nillaice, EBR sells the new rotor nut you're recommending be changed? | ||

Nillaice |

that's where i got mine, but i don't see it listed as an item on thier website. ... maybe send them an e-mail. your other option would be a stealership. and you don't need special tools to get your rotor off    i used some 1/4-20 allen bolts and nuts to do it, but longer metric M-8 (IIRC) bolts would do the trick easier, cuz they thread right into the rotor => no backing nut necesary. ... i just used what i had in my bolt bin | ||

Timebandit |

I didn't have that such a problem taking the rotor off. My rotor just pulled right off by hand with a firm pull, no coaxing, no tools required. But then I removed the entire assembly: rotor, sprag clutch and starter gear. They came right off as a unit without any difficulty. Then I put the rotor face down on a table, grabbed the starter gear by it's teeth, and gently lifted while twisting. The starter gear came right off of the sprag clutch without lifting the weight of the rotor. The only hard part of the job for me was pulling off the ignition cover. A 2009 rotor has a strong magnet. I see an impressive pile of gaskets in the corner of one of your pics. | ||

Timebandit |

... the new rotor nut you're recommending be changed? I talked to an engineer at EBR about this. Changing the rotor nut really isn't a recommendation. It's an absolute requirement. Some rotor nuts have been found to come loose under "sustained high-RPM conditions". (I think of that as their euphemism for high heat conditions.) If the rotor nut comes loose, that's a disaster. To understand this, it's important to think about fasteners as springs. When you torque a fastener, you're actually imposing enough torque to place the proper amount of spring tension on the nut and bolt to hold them together. The crankshaft is hardened. You won't be able to deform it to impose spring tension. The rotor nut is much more compliant. If you look at a new one and place it on a straight edge, you'll see that it is actually curved. This is because the rotor nut provides all of the spring tension to lock the rotor to the crankshaft. If you look at a used rotor nut, it won't have the curvature any more. When I checked mine it was flat. The reason you must replace the rotor nut is because the old one will be sufficiently deformed from it's previous use that it won't work as well as a spring as a new one. Your local dealer can order one for you. I got mine from EBR. (Message edited by timebandit on January 24, 2012) | ||

Yugi |

There is also crankshaft locking tool from Twin Motorcycles:  http://www.twinmotorcycles.com/webshop/artikel.asp ?guid=YXHFSC&aid=4129&cid=9922&s=&aname=Buell_1125 _RCR_TM_Crank_TDC_locking_tool_ | ||

Nillaice |

i thought twin moto's description says it is not tempered and is for locking the motor for valve maintenance | ||

Timebandit |

From their website: This tool is a easy to use tool developed by Twin Motorcycles to lock the Buell 1125R and Buell 1125CR crank in TDS for service on camshafts or timing chain adjustments. You need a tool with a hardened steel shaft if you're going to put 400 N-m on the crankshaft. Twin Motorcycles doesn't specifically say that their tool is hardened; if it's not, then you don't want to use it on a crankshaft, and you should limit it's use to their description -- servicing the top end. This is the one you want: Kent-Moore version with hardened shaft. B-48858-A.  | ||

Yugi |

BTW, crankshaft locking tool from this list costs $24.75 http://harleytools.spx.com/pdf/HD08-669_NewDealerK it.pdf | ||

Timebandit |

Get a clue, dude. B-48858 != B-48858-A | ||

Jdugger |

huh huh huh uh uh huh huh uh huh... you said hardened shaft. (Sorry, watching old re-runs last night...) | ||

Timebandit |

| ||

Nikponcherello |

So what is the diameter of the locking tool? Did anyone ever measure one? From the pictures it looks like about 7 mm ??? Can anyone confirm? Thanks! | ||

Timebandit |

Now that the thread has been resurrected, I thought I'd post this in case it helps anyone. Getting the ignition cover off and on while making sure that you don't let the stator hit the rotor magnet is a lot easier if you use the H-D alignment dowels. I think they're pretty expensive for what they are, in addition to being difficult to source from some H-D dealerships. So I DIY'd a set out of some 80mm M6 hex cap screws that I bought at Menards. Here's what the H-D part looks like:  Here is my DIY-equivalent. I just bought some M6 hex cap screws, and rounded-off the hex caps on a lathe. I didn't bother to slot them, I just put them in finger tight.  I know this isn't rocket science, but I just though I'd post this info in case it helps anyone. Here is a pic of where you're supposed to locate them:  |