| Author | Message | ||

Rogue_biker |

Please help me on suspension tuning/adjustment. About 3k miles ago I replaced the seals on my front fork and had the shop replace the fork fluid. I did not specify to them anything other than OEM type fluid and fluid levels. Upon installing my “rebuilt” forks, I immediately noticed the overly stiff damping. I have both rebound and compression damping backed all the way out and the front forks are still overly stiff on both compression and rebound. As a result, I get beat up. I remember the bike was not like this before the forks were done, although the forks still felt too firm. I am now going to take the forks back to the shop. What do I need to get done to get the forks to “loosen up” on the damping? Put less fluid than what Buell recommends? Put lower viscosity fluid? Suggestions please! I have an ’08 1125R that I ride 100% in the street. I commute on it 80% of the time. The last 20% is canyon carving. | ||

Stirz007 |

- did backing off C/R have any effect? Those orifii are kinda small and if blocked, they would certainly affect performance. - What was the "OEM" fluid they used? For heavier fluids, cold weather will make them feel stiffer, so that may be part of the issue... (I run 2.5 to 5W in mine, but best weight for you may vary) | ||

Nuts4mc |

have to agree with secret agent man (Stirz007) 5 or 2.5 wt...to the correct level/volume you can buy it here: http://www.redlineoil.com/Products.aspx?pcid=18 If i remember I needed 2 bottles HD has many "OEM" oil weights/viscosities for all the different types of bikes they build ...all heavier than 5 wt suggested above ...don't be afraid to ask questions when you get to the shop...or to be bold enough to tell them/supply them with what you want! | ||

Rogue_biker |

Backing off the C/R did have some effect but not as much as when the forks were OEM/untouched. The bike will absorbe big bumps, but small bumps rattle my teeth! It feels like the front forks don't want to compress and rebound quickly enough to react to small bumps, dips. | ||

Rogue_biker |

2 bottles per fork? | ||

Stirz007 |

If you have a strap wrench, and can get your hands on a spring compressor, the whole rebuild job takes an hour or two. Although replacement is recommended, you may be able to avoid replacing the new seals if you work carefully - I've done it when I tried a new fluid, ran it a day and then decided to change to another. You really need to take the forks off to do fluid replacement right - first to get all the oil out and then to set the levels correctly. For me - I run lighter weight when it's colder. I'd suggest sticking with a fork oil brand/weight you like, then your suspension settings will be more repeatable. The "better" brands seem to resist breakdown better. I've seen guys run the same fork oil for 10 years or more - I'm a little tougher on them so I do a full tear-down two or three times a season and a rebuild (new seals, mainly) every winter. Some race guys do it after every race. I have factory forks with Showa Race Cartridge Kit, 5 weight oil and it takes just a bit over 2 pints to do the job with 100 mm** air space. (** at least that's what I remember - I'd have to double-check to be sure) But yeah, if you have the time and inclination - do your own rebuild. Then you can make sure everything is clean, the levels are right and you can experiment to find "what you like the best". Maybe start with a 5 or 7.5 weight. At the end of the day, the stock suspension is quite good, but it will be sensitive to a change to a heavier fork oil (stiffer, more sluggish) because it's harder to squeeze that thick juice through them little holes.... (Message edited by Stirz007 on January 03, 2012) | ||

Sprintst |

Pork up - put on some weight! | ||

Nuts4mc |

2 legs per bottle????(J/K)...1 leg = 1 bottle...i think it was like 425cc...each bottle is 16oz = 473cc ( 1 oz= 29.6cc)...if you're a "purist" you gotta drain the cartage by pumping it dry ( gotta build a tool to remove the spring....a PIA) for a quic experiment drain the oil to the best of you ability and refill with 425cc (5wt) (a plastic baby bottle usually has graduated marking in both oz and cc and they are cheap) | ||

Timebandit |

baby bottle for a graduated cylinder. nice. | ||

Stirz007 |

A little over a pint per leg, or a little over two bottles for the entire job.... | ||

Rogue_biker |

I lost 60 lbs. in the past two years. I ain't about to gain all that back! LOL! Okay I will specify a lighter weight oil. I noticed on hot, muggy days, the fork is more compliant. So my guess is the oil is too heavy for my forks. I plan on removing the forks and taking it to the shop. I don't have the tools to change rebuid them myself and my weekend time is limited. I really should learn how to do it. Maybe I should replace the rear spring and/or rebuilt it too? Although truthfully, I don't ride hard enough to really tax the bike's suspension. I just want compliance and control at The Pace riding level. | ||

Stirz007 |

Fork Rebuild = Relatively Easy to do with basic tools and know-how Rear Shock Rebuild = Requires special tools and know-how - not generally a DIY job | ||

Rogue_biker |

Okay, I will buy the two pints of Fork Oil and bring it to the shop for them to use. Apologize for the silly question but: which is thicker 5 or 2.5 pt. weight? I'm seeing suggestions going from 7 - 2.5 so please clarify. Should I go to the lightest weight oil to get the compliance I need? I don't ride at the track...ever....not yet anyway. | ||

Dannybuell |

Find out which oil is in it now and decide from there. It sounds like your oil is too heavy. The major benefit of lighter (smaller number) oil? The forks will work immediately in any weather especially colder weather. 7.5 fork oil warmup times in 55F weather seem to be about a half hour. As oil gets older (sludge) it takes even longer to heat up and thin out. | ||

99buellx1 |

What kind of shop is the "shop " you are getting the work done at? I would find a local or semi-local suspension shop, or a MC shop that works with racers. They will be very knowledgeable and capable of building you what you require, and not just by putting the stuff together by the book. You may think there isn't a place like this close to you, but it may just be that you aren't aware of them. | ||

Nuts4mc |

from "vtwin forum" - the HD designation: Type "E" is 5 weight - the lightest one Type "B" is 10 weight Type "screamin' eagle" is 15 weight Type "screamin' eagle racing oil" is 20 weight see if you can find your old work order/bill and see if there is any reference to the above...good luck PS: higher the number thicker the oil - stiffer/slower the action automatic tranny fluid = 10 wt....in the old days - thats what we used/thats all we had...not a bad starting point and it's not as costly as the "special fork oils" (Message edited by nuts4mc on January 04, 2012) | ||

Rogue_biker |

Thanks all. The shop is called Mach 1 in Costa Mesa, CA. They do in fact specialize in high performance tune ups, builds, and standard maintenance. | ||

Tbowdre |

you might consider lowering the oil level a bit. Additional stiffness can be felt if the air cap is too small. Increasing the air cap will give the forks more of a progressive feel. 0.02 | ||

Timebandit |

on a related note, H-D did something like that with the FXRS-SP and FXRS-CONV forks. they had a schrader valve on the bar ends to allow you modulate the air pressure on top of the fork oil to tune the shock. | ||

Jdugger |

Using air as a spring sucks. It gets stiff as it's compressed instead of being linear. | ||

Timebandit |

when i typed that i knew somebody would say that air sucks. i was prepared for that. i was saving this reply: "I never said that it was a good solution, I just said that's the way that H-D did it."  now here's the real kick in the teeth -- we can thank Erik Buell for that. (Message edited by timebandit on January 04, 2012) | ||

Blake |

So use nitrogen. | ||

Rogue_biker |

I plan to instruct the shop to put 1 pint per fork. If the fork takes just over 1 pint, then I should have slightly more compliant damping for a smoother ride. That's the theory anyway. I will speak to them and get their opinion on it. Thoughts on this from anyone? | ||

Stirz007 |

Spend the money and buy three pints. Have the shop fill to levels specified in service manual. Only my opinion, which isn't worth a whole lot. | ||

Timebandit |

I'm missing out on why N2 would be better than air in that application. | ||

Nuts4mc |

Number 007 has a point if they pump the cartridges dry...most OEM manuals specify an amount of oil if the fork has been totally drained and rebuilt (it is empty and dry) ...you have to fill the leg with enough oil to cover the cartridges which house the valves and work on hydraulic principles...(you can't compress a liquid...the oil must flow thru the orifices in the valves to restrict motion = dampening the forks motion). the "air spring" above the fork oil is another issue as all gases respond to the simple gas law ( Pressure Volume & Temp)...as a gas is compressed (your forks compress...) it increases the trapped air temperature and in turn the air increases in pressure and your forks "feel" stiffer. ...a long time ago ('70s) guys out here were racing their desert bikes with just air in the forks (no springs) and by the end of the race they would blow out their fork seals...the trapped air heated up and increased in pressure to "blow out" the seals....not so long ago I got to inspect an old Yosh-Mladin Gixxer - the forks were vented to the atmosphere...no extra "preload" from trapped air.... Air and oil can mix and when heated can combust...Nitrogen, an inert gas is similar to air in it's properties except it will not support combustion (and it's cheap to "distill" from the atmosphere)...again a long time ago S&W used to "fill" their shocks with a "bag" of freon (R-12)...the gas would compress when the shock's shaft would enter the reservoir of oil in the shock's body....freon has very unique properties and it's temperature would change quickly as it cools when the pressure (the shock extends)is reduced. The "net" effect was a very stable dampening force/temperature regardless as to the amount of times the shock was exercised. | ||

Rodrob |

IMHO using extra air does not suck. A little progressive compression in the early part of the stroke may be just what the doctor ordered. I went from 100mm to 120mm of air and the handling on the rough track a Willow Springs was noticeably better. I have the Showa Race Cartridges. E-B-R recommends 10wt. Showa fluid which is hard to come by. Equal weight fluids from different brands can vary dramatically, so it is best to find the brand/weight you like and stay with that brand. Here is a link to pictures of how I did my forks without special fork tools. I recommend getting the fork spring compressor from Traxxion Dynamics rather than the hooks I used in the pictures. It's about 30 bucks. http://www.badweatherbikers.com/buell/messages/290 431/559809.html?1272601481 | ||

Rogue_biker |

Dropped my forks off at the shop and told them, "I want softer damping! I'm getting beat up riding my bike on these forks you guys built for me!" LOL! Well see what happens. | ||

Timebandit |

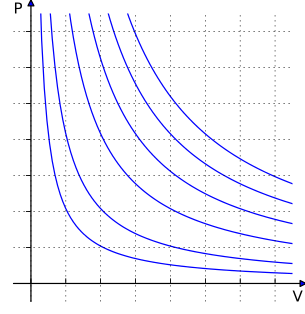

when it comes to compressing air, the results are not linear, like JD noted. here's a picture that's worth 1000 words. the plots are called "ideal gas isotherms". each line represents the change in pressure vs. volume for an ideal gas, while it stays at the same temperature. if there is enough compression/relaxation to heat the gas, you are forced to move from one curve to another. (see pic)  air behaves like an ideal gas in the temperature and pressure ranges we'd encounter. so does nitrogen. although nitrogen has some benefits in tires compared to air (less permeable to leaking out, less oxidation of rubber), it doesn't behave any differently than air in this application. that is to say, i can't explain how N2 could be any better if it really is. back to the graph. i think that what it tells us are that both JD and Rob are right. air (gas) isn't going to be suitable all by itself as the basis for a motorcycle shock because it has non-linear behavior. it's too "progressive." if you used gas in a fork, it's non-linear behavior (compressibility) would be really noticeable and you wouldn't like it. OTOH, if you placed just a little air on top of the oil in the forks, then you've got a little compressibility on rapid/short strokes that may not be all bad. i think that the reason that Erik Buell and Team FXR designed the FXRS-SP and FXRS-CONV with adjustable-pressure air-over-oil was because they understood that having a little more adjustability of the air in the fork could allow the rider to tailor how much smoothing of the ride he wanted on irregular pavement, while limiting the progressiveness of the air component in the suspension. at least that's my theory. FWIW I have one of these adjustable air fork set-ups on my the FXRS-CONV and i think that the ability to add/remove a little bit of pressure to the air in the forks does take away some of the punishment that you get on tough pavement, without adversely effecting the front end. having the schrader valve on the bars allows me to change the air pressure in the top of the bars, which allows me to shift to a new operating point on the graph. Rob effectively achieves the same results by manually removing a little oil to increase the volume of air over the oil. i've never tried this in a race bike, but in the sport-cruiser application the H-D set-up is a good solution for taking the edge off of rough pavement. | ||

Kenm123t |

Time the N2 advantage is its dry and water vapor is in all compressed air save scuba air. Throw some heated water (steam) in that chart and you will find some real crazy curves across the temperature range. If you want to diesel something over oil your favorite super high velocity air rifle. A twofer boom! (Message edited by kenm123t on January 08, 2012) | ||

Dannybuell |

In 1979 I purchased a Honda V-Twin CX500 Deluxe. In my mind it was a japanese guzzi. Atermarket shocks and springs in the back and air forks plumbed together with a dial guage up front. The front bars were from an ATC90, like superbike bars. I was loving the bike to death trying to keep up with my buddies. one on a 750 Honda and the other on a KZ1000 LTD. At 9,000 miles the CX died. Once the warranty motor went in I sold it. The air forks were great. I never blew the seals as many have complained. I stayed on the low side of the air pressure guage. |