| Author | Message | ||

Georgehitch17 |

Hey guys I have some bad news!! My Custom Rewind stator seems to be fried after only 700 miles... Its not 100% yet but I check my legs ac volts yesterday one was as low as 16 at 5k rpm the other was in the 30's and one was still at 50. What all could cause a stator to go bad other than heat??? Thank You | ||

Zac4mac |

Heat appears to be the root cause. The best solution looks like a good re-wind with high-temp epoxy and some added oil-cooling for the stator. This seems to be an endemic problem with a compact, powerful engine/trans unit. Contact Custom Rewind and I'm sure you'll get taken care of. Then figure a way to get more oil to the stator or wait for a solution externally. Zack | ||

J2blue |

Zack, another part of "fixing" when doing the rewind may be to lower the output to the 2008 specs. I don't have a lot of gizmos that eat up electrons on mine so I could go with a lower output easily. I wonder if anyone at the former Buell was able to get temperature readings on the stator at full output? How much cooling may be needed? Perhaps the heat could be calculated based on power output and other known parameters. Hmmmmm... | ||

Georgehitch17 |

the strangest part about having it rewound to the 2008 specs is that my voltage seems to be higher after it got rewound compared to what the output was after putting in a brand new 2009 stator. Im not sure if the wattage was reduced enough. | ||

Reepicheep |

Heat would be easy to calculate, but cooling wouldn't. The increment in heat between the model years would be easy to calculate also. | ||

J2blue |

Yeah, I think I am with you Bill. An effective cooling system interface to the stator would have to be known before a cooling capacity could be determined. Oil seems to be the most direct and effective way of transferring heat so an additional oil cooler was what first came to my mind. It would have to circulate well enough around the stator and through the cooler to prevent hot zones. I noticed from some of the pics of stators, both fried and not, that there appears to be a very hot zone and a much cooler zone. | ||

Dannybuell |

The design of a stator rotor has been the same for many years. A bell shaped lid that went over the stator. I call it a lid because apparently the rotax design is a pressure cooker. The Compufire company now has a rotor that is slotted/vented for big twin wet clutch systems. Is this a direction to consider? | ||

Nuts4mc |

G hitch17...how much oil was in the bike? was it low or up to the correct level?...do you do a lot of stop and go traffic - or high speed runs? how's the cooling system? recently had any leaks?...Stators usually fail when the insulation on the windings breaks down...As Zac said heat kills and breaks down the insulation ---once there's an electrical short you're cooked. Zack/Lt. Dan...Has any one (intentionally) over filled the engine with oil?..more oil might carry heat away - but it could also get "over heated" by the additional "churning" it may be subject to when it comes into contact with all the rotating parts ...just a thought. | ||

Rt_performance |

Well i am about 2k miles and mine is working fine please post some pics . I know custom rewind said a year garentee when i sent mine. have you done anything with the regulator? | ||

Zac4mac |

Steve Anderson referenced "machining" the existing rotor for cooling. I would think the compufire rotors are simply "drilled", so I don't know. Perhaps a two stage hole that will scoop oil from the bottom of the cavity and spray it on the rotor like an impeller. Drill the "pickup" from the outside inward and drill a connecting hole to spray on the stator. Angle the pickup for the rotation direction.  Zack | ||

Georgehitch17 |

In the 700 miles it took to fry the stator. It was probably 600 miles high speeds and 100 miles tops in town which in my town isnt really stop and go because its so small. The stator is coming out tonight so I can assess the damage | ||

J2blue |

Yeah Zack, that was kind of what I was thinking, too. But wondering if a small intercooler could be added in the loop to lower the oil temps a bit. Schematically that makes sense, but with the existing form factor and oil nozzle an intercooler becomes impractical at the least. I wonder how much oil pressure exists inside the housing while the motor is running? Maybe the "pickup" could be integrated into a new housing cover near the top instead and routed through an integrated cooler. I'm not next to my bike right now so I'm a little mixed up on where everything is in relation to the rider and other engine components. My thoughts are making matters more complex, too, which isn't very good. | ||

Zac4mac |

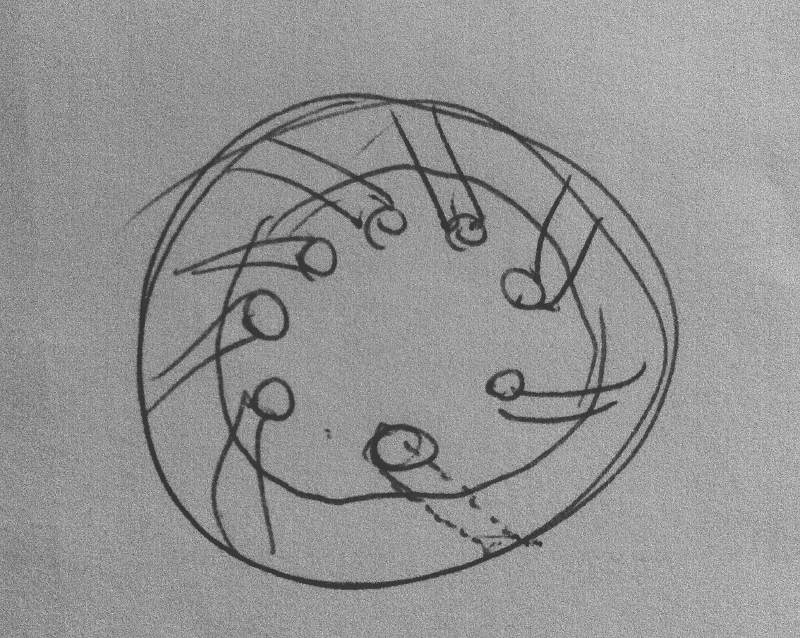

Several things in play when deciding on the rotor mod design. If you change the oil distribution in any way there will be unforseen side-effects elsewhere. So, surely not a good idea to tap an oil line and aim a jet, like one pic I saw. My idea pictured may well NOT work depending on rpm and oil viscosity - another reason to run light oil. BTW, I am NOT a mechanical or fluid engineer.. You definitely don't want to "rob Peter to pay Paul" and starve a part of the motor while trying to charge more oil to the stator. | ||

Dannybuell |

Zac4mac - That looks like the right idea. | ||

Finedaddy1 |

Hey the next time one of you guys are at the next AMA race, while you're drooling over the 1190RS, ask one of the race crew if they have any information concerning the rotor on this bike. I wouldn't mind modifying mine, if I could find someone to balance it. | ||

Nuts4mc |

drilling holes in a rotating mass is NOT a good idea: a) it will cause the part to change it's dynamic balance ( you would have to get the part "balanced" after machining) b) the part may fracture and explode due to the RPMs it is subject to. c) if you should modify the magnets in any way the field produced will change shape. better to: 1) find an "oil jet" to cool the stator, 2) build a baffle to force a new oil level for the fly wheel to "pick up", 3) increase the oil level, 4) get a bigger oil cooler, 5) make the cooling system more efficient (run straight water (distilled) and some water wetter) since it doesn't freeze in my part of the world ...I'm using (5) and a Shindengen VR...so far, this combination works well... | ||

Zac4mac |

Nuts4mc - you are spot on about the balance need, hence why I refer to it as machining, not drilling. semantics I suppose. Any modification to the rotor will have to be "finished" with a fresh balance. ANY modification would be to the steel body of the rotor, not magnets. To be safe, a full FEA stress analysis should be run on the mods(computer simulations). I hope nobody thinks they are going to get their Dewalt and a couple of drill bits going on a rotor.... This is a job for an engineering team for design and a machine shop to execute. Zack | ||

Nuts4mc |

Zac - I haven't taken a look at mine - but a simple Knurl across part of the outer surface of the flywheel (with one wheel of the knurling tool starting in the middle of the rotor and finishing on the outer edge of the rotor - may force oil out away from the engine toward the outer case and drip down on the stator...look at a crankshaft seal from an old VW - or a new one piece seal they put in American cars - there is sprial/knurl molded into those type of seals to direct the oil away from end of the block and back toward the oil pan- that is where I took the idea - a light knurl may work without affecting the integrity of the rotor... a good machine shop could easily do the work. | ||

Black |

I seriously think that even if I did the Custom Rewind fix, I would still keep the harness upgrade. Just me. Also, do you really "know" the stator failed? We had one contributor a while back state that many of the failed stators sent back to Harley had not failed. I don't know. I do know that a burned out stator looks burned....smells burned....and when you megger the thing, it shows grounds.....you can also use a multimeter to detect a short or ground.......Anyway..Good luck.....hope yours is ok. | ||

Wbrisett |

I got an email back from Erik Buell Racing asking specifically about the stators when my first one failed. In the email he said that in their talks with HD, they seemed to think that not every stator being replaced had to be replaced. No other clues, but both Erik Buell Racing and HD don't seem to think the stator is the only cause of our issues. ... I just want my 1125CR back from HD ... it's not that I don't enjoy riding my BMW and Uly, but with my daughter out of school, it's the only time I get to ride the 1125 on a regular basis. Wayne | ||

Aj2010 |

I recall one of the mods that has been done to/for the 1190 is cooling jets. I have not heard about a higher volume or pressure oil pump to go with it, or if it would even be required. I am reasonably sure these jets are simply holes drilled into the stator cover, around the bearing supporting the end of the crankshaft. I would like to know how many holes they drill, what angle they are drilled on and what diameter? as well as knowing if a higher pressure oil pump really is required or not. | ||

Georgehitch17 |

I took the stator out last night and she's cooked good. Only one third is really bad the other is mediocore and one seems to be fine. which makes sense, when i checked voltage i had a 50, 35, and 16 volt reading. Like I stated before I dont believe this stator was rewound to 2008 specs. I feel like I am somewhat to blame I rushed custom rewind to redue my stator so I could have it before the weekend and I think his employee just duplicated my 2009 fried one. This stator produced more power than the first 2 stators on this bike and more than the two previous 2008 25r's I Owned. Pics will be posted tonight... | ||

Wbrisett |

OK, so here's a question. If the 2008 stators didn't have the problems we're seeing with the 2009 stators, can we go backwards? That is, can we put in a 2008 stator in the 2009 bikes? | ||

Lampo |

Yes, no problem fitting an '08 stator and rotor on an '09 Problem is cost (unless you can find used parts reasonable) | ||

Dannybuell |

What would you have to do with the 09+ ECM's stator/harness software to accommodate the 08 change over? | ||

Aj2010 |

Here is a couple pics of an 09 replacement stator after less then 4000 Km's. It was still working fine when I removed it to replace with an 08 stator and flywheel. I just bought myself a torque wrench that goes up to 300 ft/lbs so I should be re-assembling the bike soon  ,  | ||

Froggy |

Yep, many have done it.

Warranty is great

Nothing. | ||

Htekwo |

I would think that replacing an 09' Stator with an OE 08' Stator would not be the right move. Being that the Custom Rewinds Stator is half the price of the OE unit, and presumably a better part, I would think that it would be the better choice. I had them lower the output of mine in an attempt to lower the heat. | ||

Froggy |

Can't beat free under warranty.  The 08 unit has been proven to be effective, the custom rewound ones still are yet to do that. The majority of 1125 owners don't ride their bikes 365 days a year, so it will take time to see if it really is an effective solution, or just pissing money in the wind. I am optimistic about it, hopefully it is the solution. | ||

Sportster_mann |

Has anybody that have had stator problems have the carbon case savers fitted - surely these will help to keep heat trapped in ? I also considered fitting a scoop to the side of the oil cooler to direct more air flow onto the stator cover to help keep it cooler ... | ||

Jdugger |

> Has anybody that have had stator problems have the carbon case savers fitted I have case covers on both of my '09 motors and ride them in 100+ degree heat here in Texas. On the race bike, common coolant temps are 220 or so, on the stocker, it's not unusual to see 240. No stator problems. | ||

Ratgin |

Jim are you riding either bike on the street? Race bike without headlights ect would likely make life easier for the stator. |