| Author | Message | ||

Blackflash |

I think the results would of been better if there wasnt a harley tech on your bike. | ||

Cafefun |

So dadams What would you charge to just put some new outlets on the stock pipe that turned outward away from the wheel? Can you do that without going into the pipe? just weld them over the outlets that are all ready there? | ||

T_man |

D_adams - I don't know if this helps but when I installed my HPE exhaust I initially richened it up... only to have the bike flood itself and leave me pushing it home. When I got it home, I leaned it out by 10 AFV F&R and volia... she runs waay better. I would have thought it 'wanted' the extra fuel with a free(er) flowing exhaust but that simply just wasn't the case. It needed LESS fuel. I think you'll get better results with closer to 13:1. Nice to see you actually gettin' out there and doing the field work on the dyno! | ||

D_adams |

Cafefun, I dunno, use the stock tips, one hour to cut, clean and weld? Different tips, add material costs? Not sure exactly what you'd want, straight, slashed, radiused and possibly slash cut? Not sure what shipping would run you, send me a pm for my address, pipe weighs 22-23 lbs, figure on 25 lbs to ship though. T_man, I'll look into tuning, gotta sort some other stuff out and I'm looking at some other material to try for the outlets just for the fun of it now. I have $$ and time to burn, winter is almost here. | ||

Blackflash |

I was also wanting to add that when i purchased my ohio tune I noticed the noise changed it was slightly louder and stronger sounding than with the stock tune.Revved alot harder. | ||

Easyrider |

It took me more then 1000 dyno runs to make our Torque Hammer exhaust for the 1125. Exhaust developmend is one way sience and the other way just dong it.. DAdams, I appricied that you went all the way from A-Z That's the way it should be, and when there is not the result you like, Sit, think about it, and do it again.. | ||

D_adams |

I'll be ordering more tubing as well as the other stuff I need for the other project I have going on Thursday or Friday this week. I'll see if I can get some 45 degree tubing and straight stuff for making the outside mod for guys that don't want to change the sound of the pipe. Any suggestions on what options would be favored most? Slash as shown but with no internal mods, straight cut on an angle, radiused and slashcut or radiused and straight cut? I can do pretty much anything you'd want, 304 or even 321 stainless steel. Another option is just re-use the stock tips. Easy, I've done a total of maybe 11-12 runs now, just to compare baseline to the mods. I wish I had that much access to a dyno to do tuning like what you do. Gateway just got a permenant dyno installed last weekend, so there's one available, but it will cost me a bit of change to keep using it. | ||

Geforce |

Any updates? Thread is about to go archived. | ||

Blackflash |

Its where it need to go with all the other failed attempts.Any local welder would love to weld stainless tips on a pipe for 100$ Shipping rates are ridiculous on the heavy cans also.$50 to $60 in shipping both ways within a couple states.Tips looked nice but mod didnt go well. | ||

D_adams |

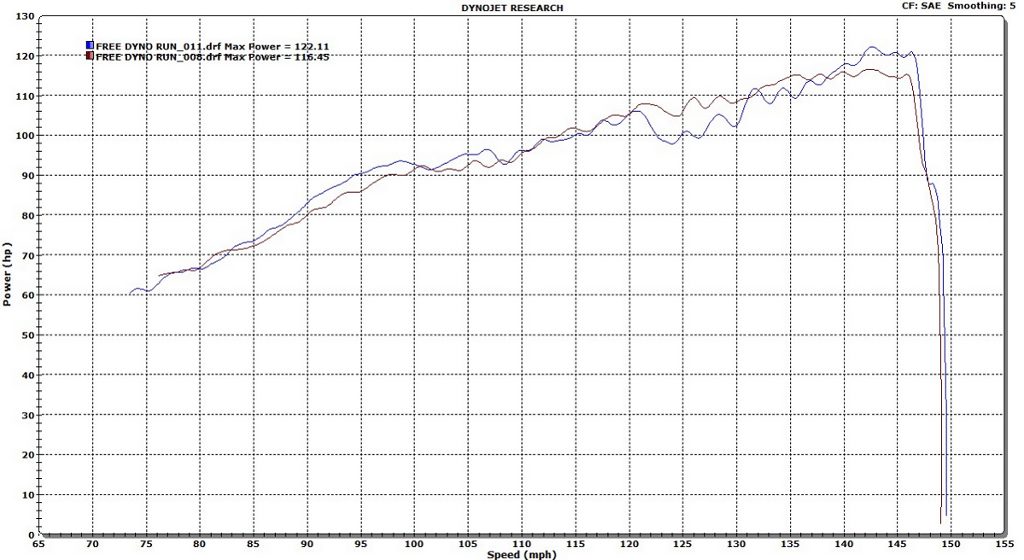

Waiting on tubing to show up. Had the 062 flash done today, if you haven't had it, go get it. Seems even smoother in the midrange. I need to schedule another dyno run to see what it really did. I do know there were some software changes in the diagnostic mode. Blackflash, who says it's a failed attempt? Just because yours didn't work out, doesn't mean mine didn't. I learned something from it. Look at the hp/torque curve compared to stock. Other than running rich, I'd call it good. Slight loss of peak hp from running rich. Much smoother EVERYWHERE else. Oh darn, total failure again.... not. Just for reference, I'm not ashamed to show the results. The blue line is stock, red line is modified.  | ||

D_adams |

Btw, archiving is fine by me, there's always the awesome search function, or a new thread could be started. | ||

Blackflash |

Your right its not a total loss.That dip at 120-135 mph stock blue line is normal but with the stock can and the o s b tune mine screams in that area now.That was the worst area when i raced my buddy in his 01 r1 .He would pull hard on me in that area. But with the tune its pretty close.Leave your pipes alone everyone, Buy a tune!!! Its a shame dave doesnt get hooked up with more people from this site .They dont know what the best bang for the buck Is.And they dont have to resort to this crap!!! Headed to dragway 42 sunday to get some et slips with this tune. Your right its not a total loss.That dip at 120-135 mph stock blue line is normal but with the stock can and the o s b tune mine screams in that area now.That was the worst area when i raced my buddy in his 01 r1 .He would pull hard on me in that area. But with the tune its pretty close.Leave your pipes alone everyone, Buy a tune!!! Its a shame dave doesnt get hooked up with more people from this site .They dont know what the best bang for the buck Is.And they dont have to resort to this crap!!! Headed to dragway 42 sunday to get some et slips with this tune. | ||

Blackflash |

Your right Ill start a swiss cheese airbox modd .  | ||

Redscuell |

Dadams, I think you should be encouraged by making progress; good on ya for giving it a go, as we say here. I do think you'll need to adjust your understanding of how the oem muffler works to make a gain over it. There is no meaningful restriction in the muffler (assuming that mixing the gases from both cylinders is a good thing; given that it's not done on bikes like Honda's VTRs and Ducati's 1098s etc.) except the final exit into two less-than-half-size outlet pipes. I predict that when you make those two pipes into 1 3/4 inch versions (REPLACE them, not ELIMINATE them as you've done), you will get the power and sound improvement you're wanting. My Third Pipe Option accomplished both (136 hp, thumping sound, 111 tq.), so yours should be able to equal it with two x 1 3/4 inch exit pipes. (Message edited by redscuell on November 13, 2009) | ||

Rpm4x4 |

Blackflash, why do you feel the need to continue making an ass of yourself in this thread? There are thousands of other threads on Badweb. Click on one of them. | ||

Blackflash |

RPM4X4 I want to add that your xb is badass.I wish I would of kept mine.1 bike is enough though. Besides that I just want to inform people about what is available .Many people have chopped these pipes and found the results are horrible.And if I can keep people aware of this they will spend there money wisely.Thats all.I was one of the first 08 1125r owners and have spent money on all the new crap that was completely junk,Needless to say I passed the junk on to someone else which then passed it to someone else and so on.Im just letting people know whats the best bang for the buck and what works!!These bikes arent 15k rpm machines and they dont have characteristics of a inline.So opening the pipes will do very little unless you go with a full system.Thats what adams really needs to concentrate on.Thats the ticket.I never bashed his work just his theory on how the pipe worked.And what was removed.His tips were nice .But any joe in town would love to have that job for 100$ .Money shipping & all that crap just isnt worth it to the average joe.So wait for a good answer or hit up your local fab shop or local buddy.Easyrider knows hes even done this stuff already. | ||

Blackflash |

http://www.badweatherbikers.com/buell/messages/290 431/514170.html?1258221412 Exactly what im talking about here. | ||

Redscuell |

"So opening the pipes will do very little unless you go with a full system." Not true, if it's done properly: I'm at 136 hp / 111 tq at the rear wheel with my 'third pipe', and scheduled to boost it a tad more when it's remapped to suit my custom s/s intake stacks in a few weeks' time. | ||

Fresnobuell |

111 tq at the rear wheel with my 'third pipe' Really? | ||

Blackflash |

Go buy a tune, leave your pipe alone ,and you can save time and money that you blow everytime you dyno a new pipe. | ||

Torquaholic |

"111 tq at the rear wheel with my 'third pipe' Really? ...111Nm in Oz should equal 81ft.lbs in our territory. | ||

D_adams |

Tubing showed up today, I'll get it cut tonight and try a test fit tomorrow. This one will be a little bit different, I'm using radiused tubing this time to turn the exhaust out a little bit more. Possible pics tomorrow. | ||

Geforce |

Right on Dean! I can't wait to see it. Keep up the good work. Call me if ya need any input for this round. | ||

Cptncreme |

what if you clear out the cat. converter like on a car? I think that would help with sound and power, since the slip-ons get rid of it completely. | ||

D_adams |

These are 49 state pipes, no catalytic converter on them. The header pipes go into a collector, then to a 2 1/2" pipe to the back and then back and forth until it comes out the exit. Just multiple chambers for muffling the sound. | ||

Redscuell |

"Really? ...111Nm in Oz should equal 81ft.lbs in our territory." Really. The dyno maps have already been posted and vetted. | ||

Fresnobuell |

I knew what you meant, but it's confusing for some. | ||

D_adams |

Ok, revised tubing pics. It's not cut to the correct length yet, but here's the general idea/shape of it. Straight out, slight overlap tilted down.  Tilted down a wee bit more...  Pretty much dead even here.  Square cut top view. Not sure if I like this, but just for reference, here it is.  Top down with a mild slash cut, maybe 25 degrees across. I didn't actually measure this, just guessing.  Straight on rear view for reference.  Roughly 1/2" to the left of the pad, this is how far out they would extend. Essentially flush with the side of the existing sheetmetal, maybe just a hair more past the edge. I got the wrong angle with the camera, so it looks longer than it should.  | ||

Blackflash |

I thought the slash cuts you had looked pretty good.This tubing your installing is this replacing the 2 tubes you took out?I recieved a can in the mail yesterday that i won on ebay and will fab my design.What size tube is that 1 7/8". | ||

Geforce |

I thought you refused and condoned modifications to these exhausts? You have been flinging crap at us the entire time about this. Dean, I like the setup. And I tried my hardest to find some data online about slash cuts affecting performance due to turbulence and I couldn't find anything. Not saying it isn't real or doesn't exist, but we should find some more info out for sure. |