| Author | Message | ||

D_adams |

Easy, could you PM me the name of the software in question? I realize it needs to "stay in house" so I'll keep it that way. I'm not a dyno operator and have no need for it other than to ask the guy running it what he has. Mike, you are partially correct. I think I've already failed now. It runs good, it sounds good, it has no flat spots that I've felt anywhere throughout the rpm range. I have not convinced the general public at large that I've done it right. Yep, I failed in an epic manner. I'm starting to believe what I read on the internet. Everything.  | ||

Easyrider |

D_adams, Blackflash is right .. | ||

D_adams |

Ok, I'll bite. What, exactly, is he right about? The software? Or is it something else I missed? | ||

Blackflash |

Im letting it go for now.I just dont want others to ruin there pipes and make the mistakes I made. | ||

Avalaugh |

Woooooo, think us mear mortals are so lost now  So on Saturday afternoon, will we have a winner haha. I reckon most owners dont want/need anymore power, as most will be road riders ! what we do want is more noise and the same great riding bike as standard. Bring on the weekend.......... | ||

Markrd500 |

Like Ive always said it take a genius to make a perfect flowing pipe.Buell had tons of r&d in this pipe. Is that the same R+D that spent time on the fuelling, routing of the front brake line, fitting of the seat, indicators, gearbox lubrication and dipstick design? O dear, have I said too much! | ||

D_adams |

You know, the guy I ride with regularly always teases me about my Buell. He's always ragging on and on about it being a HD. His suggestion was to add the fishtail pipes off of a bagger to make it look right. I might just go that route now, since I have the pipe design all wrong. | ||

Blackflash |

Heres a scheme for you adams?  | ||

Blackflash |

I admit I have to much time on my hands. | ||

Avalaugh |

dudes, kiss n make up, just use each others info to improve your own designs. were all in it together  | ||

Bob_thompson |

Avalaugh said, ".......just use each others info to improve your own designs". I think this is a great idea. I have learned much from these kind of conversations. Following this thread I have seen what I think are some mistakes, maybe not, but that is what trial and error fabricating is all about. As an example: With yours Blackflash, when you added the screen to your outlet you might have tried a CONE shaped perforated baffle to have enough exhaust square area for at least sufficient flow. I believe your flat screen too much restricted the flow. Just a thought so both of you guys, and anybody else, keep the ideas coming. Great stuff for us home designers/fabricators. Bob | ||

D_adams |

I actually have a couple of other designs in the works besides the modified stock pipe. One is a 2 into 1 turbo style all SS slipon, the other is a 2-2 with a crossover X-pipe. That one will take a bit more work though. Figuring out how to hang those cute little tassles that the man from ohio came up with is gonna be the hardest part. I might have to sub out some work. I dunno if I'm qualified to do that complicated stuff. Any volunteers for that? | ||

1buell1125r |

this has been interesting!  | ||

Bob_thompson |

Dean, forget about the bling and keep on with the brunt(grunt) of this matter. I'm looking forward to the 2 into 1 SS turbo system and how it compares with my own. Bob | ||

D_adams |

The 2-1 is about 1/2 completed, you've seen pics of it. It got put on hold for this project though. You should have yours run on a dyno, I'm curious about what the results would be. The Drummer is supposed to get 10-15 hp, maybe more in the midrange? Yours and mine are similar in design, just different size tubing. Drummer, 2", yours, 2.25", mine is 2.5" and the Buell race pipe is 2.5" although the race pipe is ungodly loud I've heard. I'm sure the results will vary widely, but with a baseline run on each, it should prove interesting. Almost like a mini-dyno shootout. Btw, I was kidding about the tassles crap. I'm horribly overqualified. I'll leave that to the guys that need distractions from the performance related issues. As cute as it is on my bike, I'm thinking it won't help much. I will say that the wife liked it. She thinks this whole "You've RUINED THE PIPE" stuff is downright hilarious. | ||

Avalaugh |

Saturday afternoon now here in the United Kingdom..... waiting for some dyno figuers kids  | ||

Torquaholic |

Dean, in case you haven't been able to get the measurements. I ran a quick set of measurements on the spare headers I have. ID of the header inlet at the exhaust port: 28mm, roughly 1.125"(x2) OD of the header inlet at the exhaust port: 31mm, roughly 1.25" (x2) OD of the larger primary where it meets the Y-pipe: 1.75", roughly 45mm ID of the larger primary where it meets the Y-pipe: 1 11/16", roughly 43mm wall thickness of the larger primary tube seems to be spot on at 1mm thick. I don't know what gauge that converts to. these measurements are the same for each header. I don't know if that helps anyone. That's what I just came up with, using a cheap manual Vernier Caliper. --Kevin | ||

D_adams |

Loading up to leave now. Give me a few hours to run down there and back. | ||

D_adams |

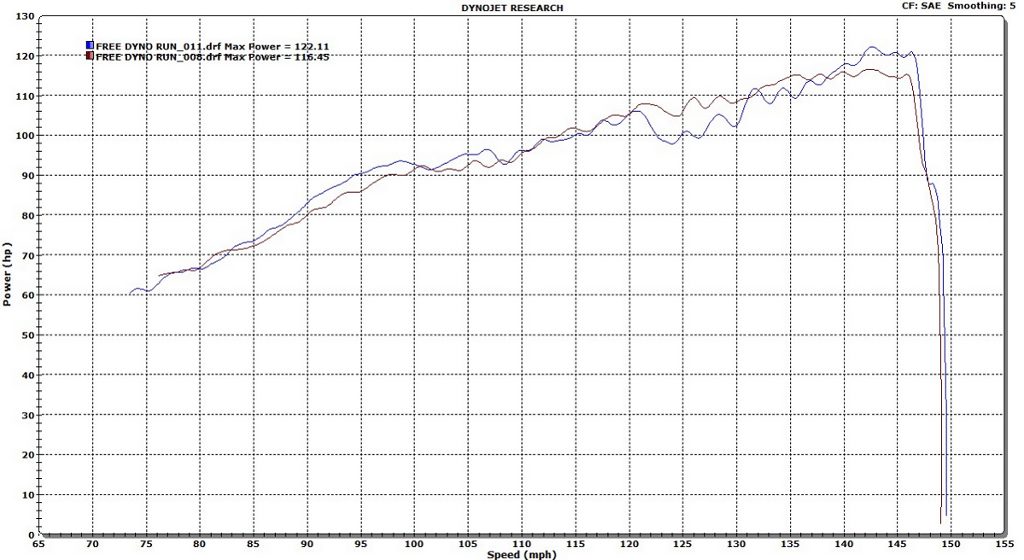

Ok, huge disappointment, no massive gains. Actually lost a little peak HP. I'll post the dyno sheets and videos in a bit, need to get a bite to eat. Looks like the stock pipe ran at 14:1 air/fuel and the modified one was actually rich at 12:1 so that's where it lost power. One major gain was how smooth it is compared to stock. Torque curve was considerably flatter and smoother, even though it's down 2 ft/lbs peak. More to follow in a bit. PS, it topped out at 174 mph. | ||

D_adams |

Weird, still no torque curve in the drf files. I saw it on the machine, got the raw files from it, but no torque values now.  Anywho, I lost 5.5 HP peak, gained some in the middle and smoothed it out a lot. The torque was even smoother, but I have no idea where it has wandered off to now. Also, it ran rich with the modified pipe, ie; 12:1 air/fuel. Very consistent across the board, rich all the way up. I wonder if leaning it out would regain the lost 5 HP.  | ||

Milleniumx1 |

On the forced induction cars I've built and tuned, I generally go a bit rich (on purpose) even though it costs me a few digits on the dyno. You don't race dyno sheets after all! BTW, your integrity has been noted - Not many people would put that many hours into something, listen to some online naysayers, and then admit they didn't get what they hoped. Keep at it Sir! (Message edited by milleniumx1 on November 07, 2009) | ||

D_adams |

Audio quality absolutely sucks on this one. Totally overwhelmed the mic on the phone. | ||

Lew360 |

How did it go rich? I "assume" you are using a stock tune and I can't figure out how more flow would cause it to go rich. | ||

D_adams |

At this point, I really don't know. I guess I'll be looking into getting some wideband o2 sensors and a controller. The air/fuel was almost perfectly flat on both runs. All I can say is, it sounded freakin awesome. Just wish the mic would have not gotten overwhelmed. 174 mph at WOT sounded unbelievable. I guess I could just do the O S B tune and force a drop of 10% fueling and run it again. Out of time to play with it this weekend though. I gotta work tomorrow and have a lot of other stuff to get done today. | ||

Geforce |

Dean, don't beat yourself up. I'm not upset with it at all. We learn from failure and even though there is a lot to be curious about, now we can try something a little different and see what happens... if you are still up to it that is. This is certainly a good start. | ||

D_adams |

After doing some light reading on air/fuel ratios, 12:1 isn't actually a bad thing. 13:1 would be better, but at this point, it may not just be fueling, but ignition timing instead. http://www.bristoldyno.com/tech/airfuel.htm

Certainly food for thought. I'll have to invest in some additional equipment now. | ||

D_adams |

| ||

Geforce |

Dean, do you need me to bring you my 1125r and some additional cash for an OH-SSS-Bee tune? I leave monday morning... if the weather is nice I can ride it up to ya if you have room. Or we can guinea your 1125r, don't bother me. | ||

D_adams |

It's up to you. Mine is here, I don't mind the wear and tear, it was built to run it's ass off. If you want run yours up my way, that would be fine also. I also have room, so take your pick. Gateway's dyno is supposed to be operational now, I stopped by and talked to Buzzie on the way back home earlier. He said they were just sorting out software bugs, etc. I guess the speed sensor came in late yesterday and they got it all hooked up. I've already got a cable as well, so thats one less thing to get. I'll be shooting Dave an email shortly to find out his opinion on the tuning and air/fuel ratio changes. | ||

Blackflash |

Im gonna say add some more baffling somehow.I ran the local ohio performance tune with my modded pipe and it ran even worse.I say that the afv went rich for the reason that the backpressure is lost.Ideal afv is set at 13.2 afv for max power so ive been told by a local twin tuner.I run the stock pipe and the o s b stock utility.And she has run great ever since.Im not changing anything right now .The only other option is a cam and intake along with a full exhaust system.And I believe 99 percent of us cant cough the cash up for that. |