| Author | Message | ||

D_adams |

I have some short sections of 1.75" pipe now to show next to the stock pipe. Not sure if these will be long enough though. Gotta do some cutting first, then we'll see how it looks. I'm thinking cut off the stock outlets, open the can, cut/grind out what's in the way, put the tubes in and weld back together. The stock ID for the outlets are 1.125" and these shorties I have are 1.625", so there will definitely be more flow/sound from them. This looks to be the largest OD that can be used without changing the curve of the sheetmetal. Btw, they need a slash cut still, just didn't want to do that until I know the angle on the outlet.     | ||

Geforce |

Keep it up Dean! Still waiting on info. I'll send a message that way tomorrow and see if we can que something up! | ||

Nickg |

i am gonna put turn outs on the stock tips...I am not thrilled with the way they just blow on the rear brake | ||

Zac4mac |

Blowing on the disc as well as the can itself and the 'noid, were all designed in concert for EPA noise and best power out. The exhaust uses the brake disc as a final "diffuser" to break up the sound/air pulses. Bypass the issue and the rear wheel is Sooooo easy to keep clean. I'm not a good welder, so I got a Drummer. I DID like the way my "modified" OEM sounded, but love the sound of the Drummer. <edit> BTW, I love what you're doing, I'm still jealous  Z (Message edited by zac4mac on October 25, 2009) | ||

Tbenson |

D adams, as you already know, I am also very interested! If you can come up with some turn outs, I might just do that. I do not have any of the tools too experiment myself. Some sort of bolt on turn out would be great (no welder either), I can find someone to weld them on if not. Thanks, Troy | ||

Kevin_stevens |

The exhaust uses the brake disc as a final "diffuser" to break up the sound/air pulses. Is that what those large quarter-sized holes drilled in the rear rotor are for as well? KeS | ||

Smoke |

the large holes in the disc allow access to the rear caliper bolts for removal. tim | ||

1buell1125r |

I was hoping to modify the exhaust this winter, just want to turn away from wheel thought about pointing down. Have friend that does welding and said he would be glad to try something. Cant stand the it gets all over the wheel! | ||

Bettybuell |

I have a TM Torque Hammer that directs the flow straight out to the side and my wheel still gets dirty. I didn't realize it was the exhaust. Anyway, probably the only way to keep the wheel clean is to run the exhaust further back, like under the seat  | ||

Crkev |

I'm going to keep an eye on this, very interested | ||

Blackflash |

me too .http://www.badweatherbikers.com/buell/messages/290 431/507667.html?1256631755 | ||

Redscuell |

D Adams, unless you cut out the full lengths of the exit pipe, you'll not get the improvement you want. And if you cut them out, you'll need to have them bent into 'S' curves to fit into the outer shell. I started out to do the same thing; and wondered if rewelding the skins (it's a two-layer shell) in place afterwards would change the dynamics of the shell movement. It was so much simpler to add a third exit (which mine is 1.75" i.d.). As for the notion that the exits onto the rear wheel/rotor are for noise reduction, I'm trying to be polite here, so I won't say exactly what I'm thinking. What I can give you is facts: my cat-free muffler gave up EXACTLY the same decibels in stock form as AFTER installing the third outlet, which is directed away from the bike (and therefore the wheel/rotor). So the facts say that 'sound diffuser' is unlikely, whatever BMC's intent (claimed or actual). That was using the Australian standard test method (stationary) in an identical position on my driveway; the metre is positioned at a 45 degree angle to the uppermost pipe and about a foot away, as I recall; and the decibels taken with the engine briefly at half max-hp rpm. | ||

D_adams |

Still waiting on the go-ahead for this, so started in on the other project again. Still need to order parts for the muffler, have the tubing all cut close to what I need except for final trimming/shaping. Collector is expanded and slitted for clamping to the headers. Looks like tomorrow will be mild and dry again, so will be riding instead of taking off the stock pipe. Gotta get the rides in while I can, it (the weather) won't last much more this year. | ||

D_adams |

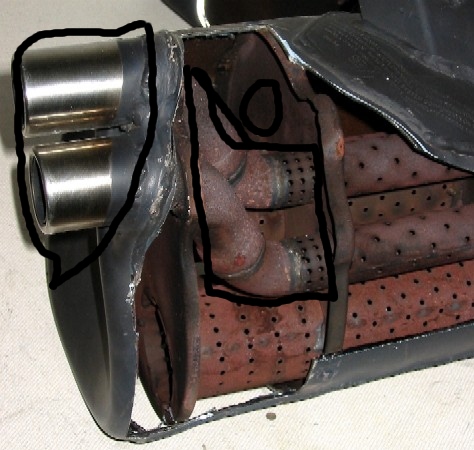

I marked the tubes to cut away, also add one extra hole to increase output for additional flow, possibly volume/sound. If the short tubes will work, no bending will be required, which is what I'm hoping for. Just waiting on a reply to get started. It's not my stock pipe we're playing with here. The other project, yeah, thats all mine. Also, the skin will be cut on top where the cutting/welding will be less visible once the pipe is back in place. The 1.75" tubes will go through both the rear wall where the original pipes exit as well as the 2nd wall in from the back. Each will be welded on the inside and out.  | ||

D_adams |

We have a GO! The green light has lit, and the cutting will commence shortly. | ||

Justa4banger |

Be sure to take plenty of pics  | ||

Rpm4x4 |

Thats exactly what I was planning to do. I was going to wait till after the snow settles in to take my bike apart. Be sure to get a sound clip! | ||

D_adams |

Looks like these 4" stubbies will work after all. No pics from the good camera yet, but the cuts I made turned out exactly how I wanted/thought. None of the pics show it, but it's been stated that it's 2 layers of sheet metal. This is correct. Looks to be 20 gauge or thereabouts, it's pretty thin. I'll try getting the outlets cut and dressed today if I can. Gateway HD is planning on having their permanent dyno running sometime in the next week or so, waiting on a speed sensor I think. If I can, I'll get this dyno'd this week again. | ||

D_adams |

I know this is just a photochopped pic, but this is sorta what we'll end up with. Kinda. The outlets will be pretty much exactly where the stock ones are, just pointed up and out. Also, not quite as large as the one's pictured here. This pic shows about 2" pipes, maybe more, so they sit too low on the pipe.  | ||

D_adams |

Cell phone pics of the cuts. Looks like the pipe is really restricted inside. Might just be me though.    | ||

Bobbuell1961 |

how strange, a rusty Buell muffler! lol keep up the good work | ||

Geforce |

You can tell this sucker didn't stay on my bike long. Dean I think you are doing great man, I should be back on Wednesday around 11. Like I told ya on the phone, take your time, no rush. I think it's going to look and sound great! | ||

D_adams |

If I get it done tonite or tomorrow morning, I'd like to put it on and test it for a few days. You mind? Ok, if it sounds like what I'm expecting, it might be a week or so before I give it up. I want to force the ecm to learn new values ( 110F/100R ) and see how it runs, along with a dyno run if possible. | ||

Geforce |

Be my guest, I have the D&D on right now, and the bike is hoisted over the cement on T-Rex stands and sitting pretty. I won't have any time to ride this next week anyways. We get done testing on Tuesday then I have to come back and do some briefings for the brass. THEN I have to go to a conference next week on the east coast. By all means... fire it up! | ||

D_adams |

Making progress, need an opinion from you Cory. Straight or slash cut? I'll cut them tonight and get pics of it that way, but even with them cut, I can go either way. Your call. They point up slightly and out at about a 40 degree angle, roughly.       | ||

Bicycle_man |

Another Rotax powered beast...I'm at work right now and this video sure makes me wish I wasn't on this sunny day. I like the exhaust outlet(s) on this one! http://www.ktm-rc8.net/fileadmin/rc8/video/vid_2.p hp | ||

Geforce |

Dean, I think you're headed in the right direction. Just like we talked about over the phone, keep up the good work! I can't wait to see/hear my new pipe! ***Provided you don't like it more than I do!*** | ||

Imonabuss |

Dean, you will go on your dick if you lean hard to the right with those sticking out like that. They will lift the rear wheel right off the ground. Of course if you're just using it for cruising, maybe OK. Bicycleman, that is not a Rotax engine. Rotax and KTM are not the same, and NOT friends. That'd be like saying a Harley has a Victory engine because they come from the same country! | ||

Augustus74 |

Buss- you missed the post where he asked the owner how he wanted the pipes cut. Obviously they are not staying like that. | ||

Geforce |

Yeah, that is just a fitment pic. They won't hang out there that much. Suspension travel is being taken into account. Dean is going to slash cut the outlets for a look similar to the Raptors and Rockets bike pictured above. |