| Author | Message | ||

Sub65chris |

ok there are ideas flowing . lets get some drawings and detailed descriptions. I am putting the construction on hold for a week or so to really get the best ideas and designs on the table. please share them all. thanks | ||

Wantxbr |

Jos51700 crappy drawing is a great idea. But that mount will have to be strong. And the upper bolts will have to be larger than the 1/4-20s you have now. (Message edited by wantxbr on May 19, 2008) | ||

Sub65chris |

Jos51700- looking at your "crappy drawing" and the first thing that comes up is the fact that the drop from the bar to the head is about 4.5 inches. so the tie bar would be at a 30-50 degree angle. kinda steep. are you including a drop portion of the braket to lessen the angle? | ||

Jos51700 |

Crappy Drawring is a mix of 2 and 3D. I would (for what it's worth), just use the cross-piece you have now for your existing bracket, and make an arm down for the tie-bar. Then I would triangulate that arm as much as possible. Think: with a true tiebar in place, the bracket isn't really seeing much fore-aft stress, as the pivot-motion in the tiebar eats up all that movement. That particular tie-bar's main job is to keep the engine (and therefore, rear wheel via swingarm) from tilting over to one side or the other. (and the front tiebar keeps the bike from folding in the middle, and the rear bar keeps the rear mount stable) So, the majority of the load the tie-bar sees is side-side. So eliminating side-side weakness will make a better handling, more stable, less-prone-to-breakage setup. Tre-D Drawring:  At this point, I'm wondering if would be possible to also tie into the top tie-bar frame mounting for some additional strength, but that may be overkill. If anything, just a bar from the top frame mount to add some fore-aft stability. Ideally, I'd make the whole thing from one piece of high-grade steel and bend it, or make damn-good welds. Also, no sharp corners. All corners should be radiused to avoid cracks. You could gusset it, too. | ||

Jos51700 |

WantXBR makes a good point, those 1/4-20's aren't as strong as as the (unknown diameter) tie-bar bolts. But, there are two of them. I don't like that they thread into an un-structural, non-reinforced, part of the frame, but I don't know how much load is going into the top mount. The XB piece is beefy, but mounted poorly, really. If strength was that much of a concern, they could have done it differently, and my spidey-sense (often wrong) says it doesn't see a whole lot of side load, you just don't want any side flex. Some redundancy here would be good. | ||

Ezblast |

9/16 on a Blast. Funny thing is though, the rear bracket they have for the Blast is just a flat with rubber added attached to both ends and bolted - no heim joints/tie bars used. EZ | ||

No_rice |

the way i see it, it has an isolater motor mount on the top in the front. it has a tie bar on the front close to the bottom of the motor. then there is the back motor mount and also a tiebar that comes off of there. so the current thought is take that most recent top mount mock up and either use a piece of angle in its place with the one side facing down towards the motor providing a more secure mount that wont twist easily. talked about using a piece of angle to run from the top down to the mount on the motor, but using the flat steel there should work better. that flat steel will stop the motor from having lateral movement because thats the way it is strongest, but will allow some for and aft flex. therefore using its strength to the advantage, but also using its weakness to the advantage. think about it, if you lay that flat bar down flat hanging off the edge it will flex a ways and spring back before it will actually putting a bend in it. lay it on its side and try to do that, its not going to go anywhere. that mild steel will alow alot of flex before ever having a problem. | ||

Jos51700 |

"that mild steel will alow alot of flex before ever having a problem." It will also transmit loads of vibration to the frame, and metal fatique will set in VERY quickly. Again, if it works that well, why isn't the factory using it? That isolator motor mount on the top, in the front, does NOTHING to control the location of the motor. Neither does the rear mount. Take off the tie-bars, and go for a ride. It's a flexi-flier. The tie-bars control the motion of the motor, and therefore the swingarm, in two axis, so it can move to isolate vibration, but not move in undesirable planes. Rigidly mounting anything to two different things designed to move around independently of each other is going to have breakage. | ||

Jos51700 |

"the rear bracket they have for the Blast is just a flat with rubber added attached to both ends and bolted - no heim joints/tie bars used. " Which "rear bracket" are you referring to? | ||

Ezblast |

The rear head engine suport bracket. EZ | ||

Sub65chris |

I think this is the braket ez is talking about.  rear tie bar that hard mounts off of the rear isolators base.  front tiebar that is being made out of threaded grade 8 rod and grade 8 ball joints. this is the stock xb bar. | ||

Sub65chris |

photo shop away so i can understand better what you mean.    | ||

Ustorque |

like this?  | ||

Sub65chris |

that is almost exactally what norice and i were contemplating today. the onlt differnence would be the top bar may get made of angle iron so I can get a nice rigid start for the mount. | ||

Wantxbr |

NO reverse the bracket that goes down to the head so it is to the right of the head. Then connect the head mount and bracket with an adjustable tie bar. The tie bar will mount Horizontally just like the front and rear. It will isolate the upper part of the motor when or if you do any hard cornering and still allow the motor to rock back and forth when idling. | ||

No_rice |

NO reverse the bracket that goes down to the head so it is to the right of the head. Then connect the head mount and bracket with an adjustable tie bar. The tie bar will mount Horizontally just like the front and rear. It will isolate the upper part of the motor when or if you do any hard cornering and still allow the motor to rock back and forth when idling. there is also an idea for a type of cradle that would also connect to the stock tiebar location and do something similar to what you described. the thing i dont think people are realizing is if you tell me the stock setup is completely perfect or they wouldnt have used it. why are things ever changed. take those tiebar mounts that i have been told pivot but but dont alow side to side movement. actually they somewhat force a bit of side to side movement. the part that bolts to the frame is a pivot point. the other end turns on its axis when the motor rocks forward or back the tiebar doesnt change length to compensate. the end bolted to the motor basically has an arced path of movement it is allowed. now ofcourse in the little bit of fore and aft movement that the motor has it doesnt amount to some big arc out of alingment, but that little shift side to side has to be there non the less. if you are telling me it doesnt have an arced path then explain to me how the tiebars are changing length.? | ||

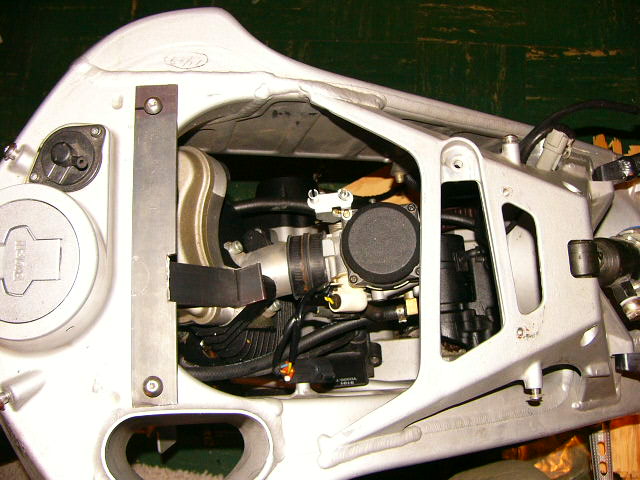

Sub65chris |

| ||

Sub65chris |

dont mind the tape  | ||

Wantxbr |

"there is also an idea for a type of cradle that would also connect to the stock tiebar location and do something similar to what you described. " Nice i'd like to see it. Never said it was perfect. no of this is perfect. Just going with what works. And its a simple design. Yes you are correct it does allow some side to side movement but not enough for you to notice riding.if you Don't have that bracket you may have a lot more that you Will notice while riding. I say use the tie bar because if you solid mount that head the bracket will break. That motor wants to rock. (Message edited by wantxbr on May 19, 2008) | ||

Wantxbr |

Not a lot of room, is there? OK I see a problem (Message edited by wantxbr on May 19, 2008) | ||

Sub65chris |

i can make a shorter tie bar in the same style of the longer one needed up front. | ||

Jos51700 |

Like I said, the big-twin/tube tiebars are adjustable. Most HD shops have some laying around in bolt bins. Adjustable is good, because you will have to "align" the wheels. Chris, your last set of pics is closest to what I had in mind, with bracing like that in the pics of UStorques. | ||

Jos51700 |

A big ol' set of straight tubing going from the front to rear wheels on either side of the tires is a good idea about now. As is the "Vehicle alignment" reading from a late '90's FLT service manual. | ||

Jos51700 |

Ow, My thumb!  | ||

Jos51700 |

Photoshop? I'm in MS Paint, man! | ||

Wantxbr |

I have a question. In the years i've been a wrench i've noticed that when bikes have adjustable tie bars there for alignment purposes but when there a fixed (None adjustable) Tie bar there all the same length. Anyone have a comment on this? I'm thinking you may be giving yourself a problem by having three different size tie bars. They wont have equal movement. I should have looked closer at the pic of the front tie rod before posting earlier. I do realize the movement is very minimal, but the top will move the least but move the motor laterally (like No Rice mentioned) the most. I just want other thoughts on this. (Message edited by WantXbr on May 19, 2008) | ||

Microchop |

yes, they must all be the same length. and think tubing (not flat iron stock) and make triangles in 3 dimensions. you want the fixed "frame" end of the mount to stay "fixed." this is not an area to compromise strength or rigidity | ||

No_rice |

well the blast ones are adjustable, and the xb ones are not....... | ||

Ezblast |

Yes - and the Blast - at least the 2000 - ran unequal length tie bars - the 2000 having an extra for more top end stability, but adds a tad more vibration - so lost in consideration of the target customer - per a most respected source - EZ | ||

Ezblast |

Use the XB bracket and a Blast adjustable Tie Bar? - something like that - Just a thought - my 2000 isn't that different in vibrational level - its barely noticeable - you'd have to trade off while both are running at idle to feel the difference. EZ |