| Author | Message | ||

Xb12mel |

Bump  Just watching! | ||

Ezblast |

me too... | ||

Sub65chris |

will be back in town this week and contiue the posts. | ||

Ezblast |

Cool...;0) | ||

No_rice |

he was just in tonight for a nice long chat, and to pick up some of the ordered parts. alot of discussion on how to go about setting the final drive up. might take a little fab work but shouldnt be to bad. | ||

Ezblast |

Rear motor-mount would be fabbed, the xb stuff mounts on for the belt, use the 05 and up hardware. EZ | ||

Sub65chris |

ez- wich motor mount? the round isolator? also why couldent I use the 03 belt parts? Will they not fit? or are there other problems? | ||

Sub65chris |

almost looks like a bike now! | ||

No_rice |

yep it does! i was kind of wondering what motor mount too. as far as i knew you already had it bolted into the frame and only had to mod the front just a hair. i was also thinking that you need to build some kind of carb support bracket yet also so you dont break a bunch of the intake boots | ||

Americanmadexb |

all you need to do know is add one of these bad boy's to bring it up to speed!!  (Message edited by americanmadexb on May 16, 2008) | ||

Ezblast |

Springs could support the carb - what did you do for a rear motor mount bracket? Looking good! EZ | ||

No_rice |

if you look on the first page. you can see the back motor mount. xb mount bolts right in place of the blast mount. | ||

Sub65chris |

Americanmadexb- lets focus on geting a running bike first. then I can sell some organs to afford one of those.  this one? ez , or do you mean the one that mounts to the rear portion of the cylender head? | ||

Ezblast |

One that mounts to the rear portion of the cylinder head - thank you. Several have figured that an L bracket would have to be used - what was your solution? EZ (Message edited by ezblast on May 17, 2008) | ||

Ezblast |

Rephrased the above - lol EZ | ||

No_rice |

my understanding is that it is going to be attempted to run without that specific one. it will still have all the other mounting points though | ||

Ezblast |

That was done on the track version, but both street Blasts and XB's have a rear one, so It must be a useful item, and only looks like an L bracket with some rubber mounted would do the trick. EZ | ||

Sub65chris |

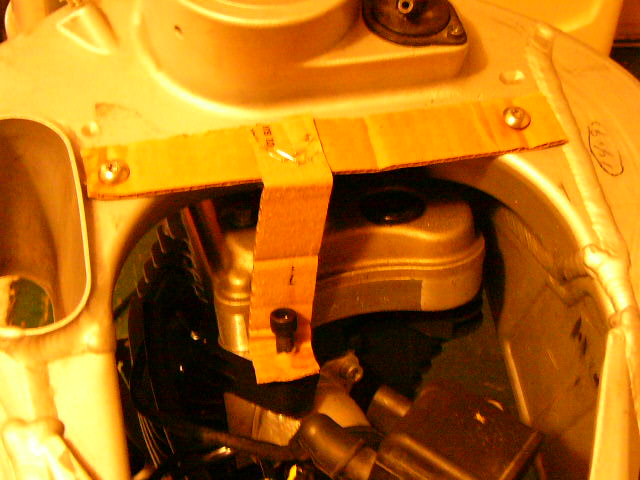

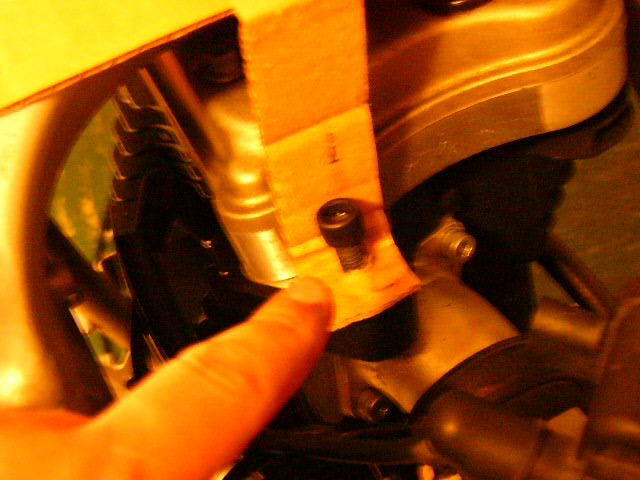

using the existing threaded holes make a strap.  weld the lower portion here  bend it here ( or weld )  posibly mount the coil here? | ||

Bombardier |

How do you go about welding cardboard? Heh Heh | ||

Ezblast |

Throw a strip of rubber on the end where its being bolted to the head and it will look factory - good job. (If you make two of them, I'd like to buy one. - please - lol) EZ (Message edited by ezblast on May 18, 2008) | ||

Sub65chris |

should have it made by tommorow night? if all gos according to plan. | ||

Sub65chris |

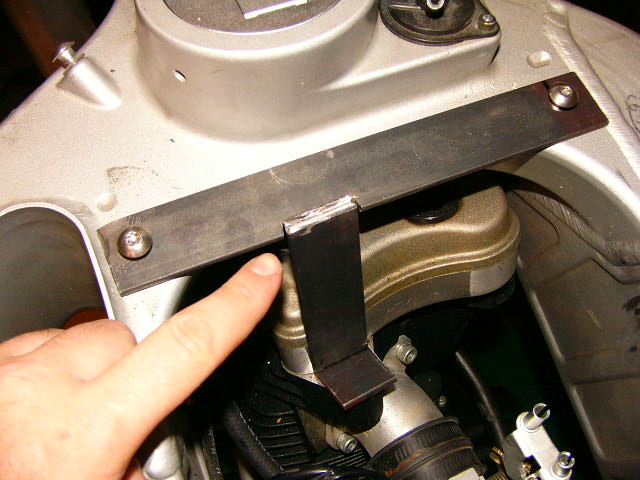

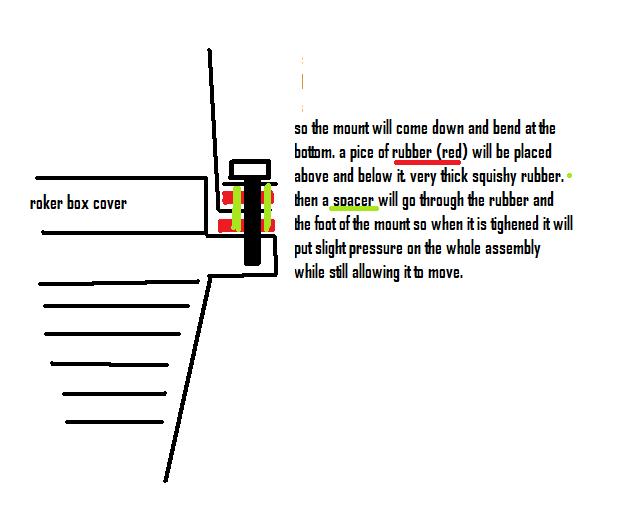

ok , now I can weld this.( when i tried to weld the cardboard is just wouldn't take to a bead.  I am going to sorta rubber mount the end of this thing so my final height will most likely be different. The notch will let me move it up and down for the best fit after the rubber is placed above and below the steel foot. I think a big washer adn a spacer will dothe trick nicely. hope my rough layout is going to work. I cant see the motor moving that much so I think this will work. any ideas or comments besides welding cardboard?  | ||

Jos51700 |

I was gonna say, that mount won't work, because the rest of the motor is rubber-mounted. It needs to have some flex in a fore-aft plane, but not in the side-to-side plane. Also, how do you plan to determine the replacement "top" tie-bar length? It needs to be correct, as it controls the rear wheel camber in relation to the front. | ||

Jos51700 |

If anything, I'd make the bracket rigid, and coming down on the RH side of the frame, with a tie-bar (from a tuber, adjustable for length so you can set your wheel alignment) running to that neat boss on the head, similar to the original Blast setup. Crappy drawring:  | ||

Jos51700 |

Transmitting that vibration to the aluminum frame would be bad for both your mount, and the frame. | ||

Sub65chris |

this is what i was thinking. as far as teh rear wheel i think(hope) I am pretty safe beacuse of the other two tiebars on the motor the one that is on the very front and the one by the rear isolator. also from what I have gathered the fireblast did not run one of the top mounts at all. Now I know that that bike didnt see everything that a street bike might but they did pretty well i am told. I am going ot continue to think this over adn not rush it because if I screw this up  | ||

Ezblast |

Looks to me you pretty much have the right of it - just about what I and Erik Oberg thought would be needed - the rubber towning down the vibration. EZ | ||

Jos51700 |

There is nothing to control the vertical inclination of the rear tire. Unbolt the top tie-bar on any Buell, and do a little gentle prying, and you'll see the movement I am referring to, and the prying is nothing compared to the deflection while cornering. The little bushing you have outlined will isolate vibration, but you should keep in mind, the tie-bars allow vibration isolation without chassis deflection, and that bushing will allow flex in EVERY direction. Not the hot ticket for a stable, fun bike. Think: To corner, the bike (and therefore, both wheels) lean over. If the rear is not kept in a stable lean, what's that going to do for your handling, stability, and of course, safety? You're not far from adding a tie-bar, and even a rigid mount would be better than a plain-old rubber bushing (Inside-collar notwithstanding). A rubber bushing would've been a lot cheaper than tie-bars. Ever wonder why they didn't just use a bushing? And, that mount will need to be fairly beefy. If it breaks mid-corner, you can guess what would happen. | ||

No_rice |

now its been awhile since i really looked at the tie rods on one of my xb's, but from my parts book pics and my memory i dont believe the tie bars had any kind of rubber bushings or such. there is the rubber rear motor mount and the rubber front motor mount, but all the tie rods connect metal to metal correct? (scratch that i just went and looked, duh we have a floor full of them lol. there is no rubber, its all solid mount metal to metal for those tie bars) sooo, if it works from the factory why would there need to be a rubber mount on this set up? maybe the blast one is different, but from what i remember it is the same way.? im thinking beef up that mount and bolt it up. i see how i think a bracket could be made fairly easy and still retain the original tie bar also. although it would need some beef to it so the bracket didnt flex around. i even have an idea for the same style bracket you have but with some more strength built in. to help that side to side movement. i am wondering if it will tweak that flat steel mount | ||

Jos51700 |

The tie-bar ends have spherical teflon bushing. They pivot. Thus allowing fore-aft movement, but without side-side slop. Solid-mount metal to metal it is not. Simply removing a bolt from one end and pivoting the tiebar out of the way should erase any doubt. I would heavily triangulate that mount, no matter what method of attachment is used. |